In the manufacture and decoration of fireplaces and stoves, the use of standard cement compositions for adhesion of individual masonry elements is unacceptable. This is due to the special operating conditions of structures that are in contact with a high-temperature environment all the time. For these purposes, a special heat-resistant glue for stoves and fireplaces is used, strong and elastic at the same time. Such requirements are explained by the fact that when heated, all components increase in size, and when cooled, they return to their previous form. When using heat-resistant plastic components, as a result of these changes, deformation shifts, cracks and even the slightest damage are not observed.

Varieties of glue for stoves and fireplaces

Heat-resistant adhesives are classified according to their purpose and application in various operating conditions. In accordance with the second indicator, they are divided into the following types:

- thermoplastic compounds;

- thermosetting adhesives;

- quick-drying and heat-resistant mixtures.

The first two names have good plastic and inert properties, which make them suitable for laying home fireplaces and stoves. The third type of adhesives is designed specifically for use in conditions of sharp temperature fluctuations, within which they retain the declared characteristics.

According to their purpose, heat-resistant adhesives for ovens are divided into the following two types:

- compositions for finishing external and front walls of fireplaces and stoves (portals);

- mixtures for laying out brick or stone bases.

When working with these formulations, you must adhere to the recommendations given in the instructions attached to the adhesive packaging.

Heat Resistant Adhesive Components

Manufacturers are trying to make the oven glue as versatile as possible by improving the following qualities:

- heat resistance and moisture resistance;

- plasticity and ability to heat transfer;

- coefficient of linear expansion.

- ecological cleanliness.

To achieve all these indicators, synthetic additives with a predominance of one or more components are added to the glue.

Formulations that meet all the criteria are classified as universal. These include such well-known ones: Terracotta, Profix, Scanmix Fire, which have a higher cost.

The following mandatory components are distinguished in adhesive mixtures:

- cement used as a binder;

- well-cleaned sand;

- fireclay fibers providing the required heat resistance;

- mineral additives of various types and synthetic components.

The latter are used as plasticizers, giving the adhesive composition the desired plasticity. Together with sand, these substances are fillers that allow you to achieve the desired consistency of the solution. Cement gives the heat-resistant tile adhesive to the stove the required strength, and synthetic additives provide the required moisture resistance, heat transfer and coefficient of linear expansion. The predominance of one of the components changes the properties towards one or another characteristic, reducing the manifestation of all the others.

Required characteristics

There are natural and synthetic adhesives on sale. Both types are used in the assembly of the bases of fireplaces and home stoves, as well as their decoration and differ only in cost. The liquid version of the glue mixture takes a long time to prepare, when applied, it dries quickly, which complicates all the styling procedures. The mixture, produced in dry form, is prepared rather quickly, its cost in comparison with ready-made compositions is slightly lower.

Before you go to the store to buy or make your own refractory adhesive for tiles on the stove, you will need to familiarize yourself with its characteristics.

- The approximate drying time of the adhesive, measured in minutes. It varies from 5 minutes for Penosil samples to 60 minutes for Zollex glue.

- The maximum temperature that the dried composition can withstand. Its values start from 120 for the Penosil brand of glue and end with 1300 degrees, which characterize a high-temperature mixture of the Diamond type.

- The manufacturer's declared value for a specific product.

The average value of the temperature index for most of the known brands of glue is 260 degrees - this is the maximum that the composition can withstand without collapsing or losing properties.

- adhesive product manufacturer;

- structure;

- performance and purpose.

Among the budget options, an adhesive mixture called Spike stands out, often used even for gluing metals. It is available in standard tubes, packaged in 50 grams and costs only 30 rubles.

The domestic brand called Super Hvat is characterized by the best value for money. The cost of a universal product is approximately 45 rubles per 100-gram package.

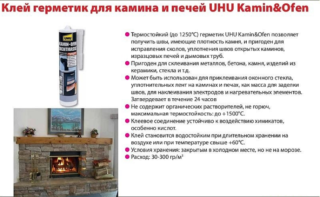

Formulations intended for strictly specific purposes will cost the user more. The price of a 300-gram package of VS-10T glue costs about 2 thousand rubles, the composition under the name UHU Metall costs an average of 210 rubles per 30-gram package.

The most important criteria when choosing an adhesive

Taking into account the following factors will help to determine the choice of glue:

- purpose - for interior or exterior decoration;

- type of surfaces to be trimmed;

- type of tile material and rate of thermal expansion;

- ecological purity of the mixture and resistance to moisture;

- the speed of drying of the composition and its critical operating temperature.

The adhesive solution for facing facades, according to the characteristics declared by the manufacturer, can withstand temperatures up to 120 degrees. When finishing embossed surfaces, it is recommended to choose a mixture with an appropriate density indicator. To meet the requirements for environmental friendliness, heat-resistant solutions are purchased that do not contain toxic components. Moisture-resistant adhesive mixtures are in demand when carrying out finishing work in buildings with a high level of humidity or outside the house. When choosing a temperature indicator, not only the upper, but also the lower limit is taken into account.

Popular brands of heat-resistant glue

- Terracotta is a thermally resistant adhesive composition (withstands up to 250 degrees), characterized by good adhesion to the surfaces of any masonry products. It is used when processing tiles or natural stones. It costs no more than 500 rubles.

- Glue Profix is a mixture used for furnishing and finishing portals, characterized by a high degree of plasticity, due to which the masonry can be carried out in a very thin layer. The maximum temperature is 1200, the cost is 455 rubles.

- Scanmix Fire is a high-temperature compound from a Finnish manufacturer, used in the manufacture of fireplaces and stoves, as well as individual chimneys for them. The maximum heating temperature of these compounds is 1200 degrees at a cost of 600 rubles.

The list is completed by Ivsil Termix adhesives, designed for durable fireplace substrates. They are characterized by a high level of plasticity and are able to withstand heating up to a temperature of 250 degrees. The cost of glue from this manufacturer is 460 rubles. The same category includes hot-melt adhesives for tiles on the stove under the Ceresit Flex CM 16 brand, designed specifically for laying tile finishes on uneven surfaces. The cost of this sample of adhesive is 600 rubles.