Domestic warm floor Warmstad - inexpensive equipment from the Teplolux company. It is suitable for installation under all types of flooring. The complete set is represented by heating elements (cable section or mat), mounting tape, protective corrugated tube for the sensor.

- Appointment of underfloor heating Varmstad

- Advantages and disadvantages

- System specifications

- Cable characteristics

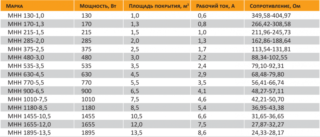

- Characteristics of heating mats

- Varieties of warm floors Warmstad

- Cable Sections WSS

- Thermomats WSM

- Film floors

- Installation of underfloor heating Varmstad

- First turn on

- System safety and operation rules

Appointment of underfloor heating Varmstad

Varmstad products provide a comfortable microclimate and normal heating of the house. The system is mounted in order to:

- heating the main floor covering;

- maintaining normal temperature;

- the main source of heat in the house or apartment;

- backup heating in case of using a heating system.

The manufacturer establishes a 25-year warranty on products.

Advantages and disadvantages

Heating devices are intended for residential and non-residential premises. They have several advantages:

- a large assortment - the manufacturer's lineup includes 16 models for different heating areas;

- inexpensive cost - real savings are provided on the repair or replacement of communications;

- quality due to multilevel protection - aluminum-lavsan insulation, XLPE sheath;

- compatibility with all types of coatings;

- warranty period of use - 25 years (from August 2018);

- ease of installation and connection.

Among the disadvantages of Warmstad floors are a decrease in the usable area of the room when using mats, the absence of a self-adhesive base, and reinforcement for punching.

System specifications

Warmstad underfloor heating is produced in the form of cables and mats. The technical parameters depend on the type of product.

Cable characteristics

The cable sections are different:

- length from 7 to 213 m;

- heating element in the form of a resistive screened cable 5.5 mm in diameter;

- the number of wire cores - 2;

- heat dissipation power - 150 W / m2;

- moisture protection IP67.

The cable is laid in a cement-sand screed or under a floor covering.

Characteristics of heating mats

The characteristics of heat looms include:

- heating area - from 0.65 to 14.5 m2;

- thermal power - 150 W / m2;

- diameter and type of cable - 2-core 3 mm;

- installation method - in tile adhesive or screed.

Heating mats are compatible with tiles, parquet boards, carpet, laminate, linoleum.

Varieties of warm floors Warmstad

The electric type of underfloor heating is a high-quality and versatile heating system. The Teplolux company produces several product options.

Cable Sections WSS

Suitable for screed mounting because cut into pieces. The base is a two-wire heating element about 5 mm in diameter. The standard kit includes a two-core shielded cable for 220 V voltage, termination and connecting sleeves, and an installation wire.

The features of a warm floor for a screed 3-5 cm thick include:

- Heat flow uniformity. Depends on the installation step.In a cool room, the distance decreases in order to transfer more heat, in a warm room it increases to capture more space.

- Electrical safety - Alumolavsan shielding on the surface of the conductors.

- Long-term operation due to polymer insulation with increased heat resistance.

- Adhesion to concrete screed.

The power of heating communications depends on the location of the cable turns.

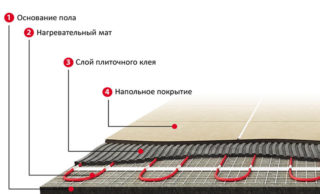

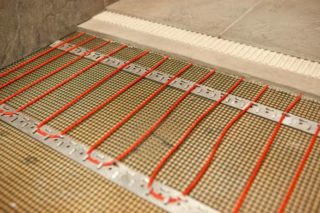

Thermomats WSM

Electric heating mats are produced in the form of a thin (3 mm diameter) cable fixed to a plastic mesh. The same pitch is observed between the turns. The standard equipment is represented by a heating cable on a roll mesh, a corrugated tube for a sensor, and couplings. The thermostat is completed with a regulator.

Warm floors are suitable for installation in any room, they allow you to keep the height of the main covering. It is advisable to install them as backup heating. The Warmstad heating mat has the following features:

- quick installation work;

- uniformity of heat supply;

- protection against voltage surges and surges of the electromagnetic field;

- preservation of the height of the floor covering due to the small diameter.

Thermal mats are not suitable for parquet materials.

Mats and sections are cable products, consisting of two heating cores for uniform heat supply, eliminating the risk of overheating. To achieve electrical safety, the manufacturer uses a screen based on alumolavsan.

The insulation is made of polyethylene with chemical crosslinking, the shell is polymer, heat-resistant. The mats are equipped with ribbed couplings that increase their mechanical strength and durability.

Film floors

Infrared construction with a thermal output of 150 W / m2 is made from fine carbon filaments baked in flexible plastic. 3 micron carbon materials are processed at a temperature of +140 degrees.

The film product is installed under all types of coatings, it is distinguished by its power and energy efficiency. Carbon is used as a heating element, laid along the film in thin lines. The advantage of infrared floors is uniform and fast heating in 5-40 minutes.

The set of IR films does not include a temperature regulator and thermal insulation.

Installation of underfloor heating Varmstad

Before starting installation work, the permissible wiring power is calculated by summing all household appliances. You can consider the installation process using the example of laying mats.

- Preparation of an even coating. The surface is primed to improve the quality of the adhesion, cleaned of debris and dust.

- Screed organization for uneven floors. The heating line will be located on the reinforcing mesh.

- Preparation of the layout scheme. For the correct distribution of the mats, a drawing is drawn, which indicates the installation points of the thermostat and temperature sensor.

- Installation of mats according to the scheme or cable tie on nylon clamps. The product can be cut without touching the veins. When laying out, the coils are at the same distance - about 5 cm.

- Compliance with the distance from the walls - 5 cm.

- Grounding the mesh with a copper wire through the thermostat when laying in the bathroom.

- Installing the regulator 80-90 cm from the tile in a convenient place.

- Installation of the temperature sensor at a distance of 50-60 cm from the walls in the tube.

- Closing the tube with a plug and checking the free play.

- Laying the cable in a pre-punched wall.

- System health check.

Warm floors in wet rooms are installed without regulators.

First turn on

A trial run of the system allows you to check the quality of the installation, the functions of the main elements and the quality of heating. Testing is done like this:

- Turning on the power supply of the warm floor.

- Starting the thermostat and leaving it on.

- Inspect the mats for heating.

- Turn off the thermostat and the system.

At the time of the initial start-up, the thermomats will heat up in 8 hours - 2 days, depending on the floor area and the purpose of the communications.

System safety and operation rules

The manufacturer offers instructions for use in conjunction with the passport of the device. The document highlights the features of the system.

- Installation is carried out on a screed from 3 cm (cable) and glue (mats).

- Installation of cable sections is carried out under the screed of laminate or parquet, mats - under tiles or natural stone.

- Before installation work, check the conformity of the underfloor heating to the heating area.

- One cable or mat cannot be laid in two rooms.

- When connecting, you must be guided by the color of the insulation of the cores. Yellow-green is thrown to the ground, brown - for a phase, blue - for zero.

- The thermoregulation sensor is connected to terminals 1 and 2, alternating voltage is applied to terminals 5 (zero) and 6 (phase).

- Mats and cables are connected through an RCD with a rating of up to 30 mA.

- Heating products from 2 kW are connected to a separate line through a difavtomat.

- Do not put mechanical stress on the mats.

Safety regulations:

- Neat cutting of the mesh at the time of laying. Other deformations and breaks in the material are unacceptable.

- Connecting the system to a 220 V network.

- Connecting products through a thermostat.

- Elimination of the influence of greases and oils on heating devices.

- Use soft shoes or cover the cable / mats with plywood while walking.

- Full filling of screed or tile adhesive.

It is better to entrust the maintenance, installation and repair of the system to specialists.

The operation of underfloor heating Varmstad, equipped with thermostats, allows you to reduce heat loss in the room. The equipment is economical, because heating consumes 30% of electricity. You can choose systems in the form of a heating cable or thermomats for any type of coating.