The used equipment is dismantled and replaced with a new one to improve the thermal regime in the room. Removing the heating battery is a simple process if you know how to remove the radiator correctly. The work is carried out in the summer so as not to drain the water from the main. The thread is unscrewed or a grinder is used if a welded joint is used.

- Situations for dismantling a radiator

- Dismantling methods

- Fitting connection

- With the help of squeegees

- Cutting off the heating agent supply

- Top connection

- Bottom connection

- American women

- Squeegee batteries

- Welding battery

- Materials used

- Mounting radiators on the wall

- Installation of through and blind plugs

- Pressure test

Situations for dismantling a radiator

The works are carried out independently in the technological sequence. The equipment is removed carefully if further use is required. The brackets must remain intact, otherwise they will require additional reinforcement or replacement.

Batteries are removed for various reasons:

- Leak between sections. The radiator wrench does not reach the nipples behind the blind plugs. The heater can be removed from the supply side.

- Leak in the place of the eyeliner on the squeegees. Dismantling is required to change the threaded pipe section.

- The need to replace the radiator with a device with different characteristics.

- Prevention. The sections need to be descaled and replaced with gaskets.

- Renovation of the room. The batteries are dismantled to decorate the wall behind them.

Removing the radiator is required if the system is being converted, for example, from a one-pipe circuit in a house to a two-pipe one.

Dismantling methods

The battery is removed during the heating season after the riser has been emptied. In a private house, this concerns the owner, and in a high-rise building, the permission of the management office is issued. The service is paid and is carried out at a convenient time for housing and communal services. Most heating devices are equipped with blocking valves, the coolant ceases to flow to a separate section.

Fitting connection

The thread is retained intact if the center-to-center dimension from one connection to the other in the new device is similar to the old battery.

Dismantling procedure:

- The locknuts are twisted along the connections with plugs. If a layer of paint interferes, the connection is warmed up with a hairdryer or blowtorch. The old winding is removed from the thread.

- The radiator cap is unscrewed using a gas wrench number 3 or 4. Usually, a right-hand thread is used for side connection.

- The radiator is removed from the holders.

- Radiator plugs and locking elements are twisted on the liner.

The existing connections are cut off if it is planned to transfer the heater, install a tap, thermostat, or re-install it on American women. In fresh areas, a new thread is made for taps or fittings.

With the help of squeegees

The tightness is ensured through the use of a two-nut system. One connects the radiator to the pipe, the second is a locknut. An element of a smaller size is unscrewed along the length of the cutting of the squeegee, then they also come with a connecting nut. The process is carried out on the supply and return lines.

The radiator is removed from the mountings. Cast iron products are heavy, so help is needed, or the radiator is split into separate sections. Water remains in the battery, so rags are used so as not to flood the neighbors.

The problem appears when the joints are rusted and become immobile. The blowtorch helps or the joints are cut off. The remaining length may not be enough for a new cut, so an additional squeegee is welded on.

Cutting off the heating agent supply

Before unscrewing the battery, turn off the system and drain the water. In individual heating, in order to remove the battery, the circuit is drained from the stove.

In a multi-storey building, the options depend on the design of the heating system:

- Newly built apartments have a separate circuit. The water is shut off by a tap embedded on the way from the riser to the radiator.

- In the old residential area, the water is cut off in the common riser, and the valve is in the basement.

- The last installations are carried out with a bypass insert on the battery. The specified valve opens, the coolant supply valve closes, after 5-7 minutes the outlet valve is turned off.

It is easy to disassemble a bimetallic heating radiator or an aluminum battery, since a Mayevsky tap is installed on them for safe draining of water. On inexpensive models, a plug is installed that can be unscrewed with a wrench. The thread can be right and left, you need to be careful not to break it.

Top connection

In this version of the wiring, the shut-off valve is located in the attic. It overlaps, but the plug remains in place. In the basement, the common riser and the distribution of the return flow are turned off. In the attic, the plug turns a couple of turns and you need to wait until the pressure of the water flowing down the thread decreases. A decrease in pressure indicates the serviceability of the locking devices.

The plug is unscrewed completely. The suspended coolant will merge after opening the supply pipe to the battery.

Bottom connection

The riser on which the radiator changes, and two adjacent ones overlap. Valves on adjacent risers are closed to reveal a twin riser. Then the plug is unscrewed on its own and the cranes on the neighboring ones are started one by one. Opening the shut-off device on the twin riser will discharge the coolant. This valve closes, the second one starts.

The saddle or bottom connection is carried out with a two-pipe system, a valve is installed at the outlet and inlet of the pipes to shut off. The valve closes, the branch pipes are disconnected, the pipes are displaced to the sides or down, the radiator is removed from the brackets.

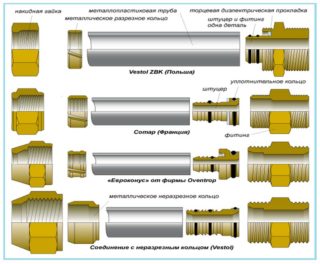

American women

The nuts have a right-hand thread and are screwed in with a pipe or open-end wrench. You can remove the heating battery in an apartment on American women in a short period of time. The supply pipes are separated from the radiator plug by 3-5 mm, then the battery is removed from the hooks. Sometimes force is required to straighten the steel lines in the case of diagonal connections.

The American for polypropylene pipes is characterized by the presence of a clamping nut, unlike other fittings. To disconnect the heating equipment, it is unscrewed until the counter section becomes free. Then part of the tube is removed from the battery.

Old fittings crimp the valve outlets, over time, the thread takes the form of a counterpart and is not reused. In this case, the squeegee or shut-off valve is changed.

Squeegee batteries

If the connection is on one side, the lead-through plugs have a right-hand thread. The diagonal connection is characterized by the fact that one of the bushings will have a left one. The opposite movement is indicated by the letter L on the surface of the plug on the same side.

A pipe wrench is used to rotate the cast iron plug. Sometimes heating of the right-hand section manifold is required, which will lead to easy unscrewing. The squeegee is simultaneously screwed into the radiator by unscrewing the left sleeve.If there is a thread on the connection, the converter plug cannot be removed, but the squeegee is dismantled from the coupling. It will slide into the plug hole, and after removing the battery, it comes out of the socket without effort.

Welding battery

The welded joint belongs to non-separable types, therefore, the places of the connections are cut with a grinder or a hacksaw. For a power tool, a circle is used for working on metal. The cut is guided at right angles to the longitudinal axis. A new thread is made to connect a cast iron or bimetal battery, it may be necessary to lengthen the underwater and outlet sections by welding.

Materials used

Galvanized steel pipes are used to change the system or lengthen the supply lines to heating accumulators. They are joined by threaded connections, no welding is used. The melting temperature of steel is + 1400 ° С, and of zinc - + 900 ° С. Zinc completely evaporates in the weld area.

Components required:

- blind and pass-through radiator bushings;

- two shut-off valves;

- paired locknuts when installed on squeegees, their size corresponds to the diameter of the connections;

- brackets for fixing the convector on the wall.

Sometimes corrugated stainless steel pipes are used. Durable products bend, compression fittings are used for connection, installed with adjustable wrenches.

Mounting radiators on the wall

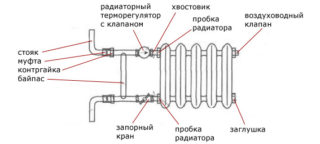

One ball valve is replaced with a thermal head or valve to coordinate the degree of heating and cooling of heating equipment. The throttle (valve) is manually adjusted and the thermostatic element works automatically.

Residents of the upper floors put air vents on the radiators to remove accumulated air. Mayevsky's cranes or automatic devices are installed. In a multi-storey building, the connections to the battery are equipped with a jumper to the valves or throttles. The connection ensures the movement of water in the riser when the underwater section is closed. Full or partial overlapping of the liner without a jumper will lead to cooling of the batteries from the neighbors.

Installation of through and blind plugs

The grouping of sectional collectors is completed by installing bushings in the required combination, which depends on the scheme. Plugs are deaf and straight-through. Blind elements do not have through holes, and the external thread does not differ from the through holes.

Pass-through products are distinguished by a central hole. Both types are available with left and right threading, since the battery section has two corresponding inputs. You can turn the bush on a lathe from steel, cast iron or brass.

Pressure test

The joints are checked under pressure after mounting and connecting the heating equipment. An electric or manual compressor is used that blows atmospheric air. The test is carried out to identify leaks in the system.

Procedure:

- shut-off valves are closed;

- the plugs are wrapped and the air vents on the risers are closed;

- one valve opens on the riser and fills slowly;

- after the hissing sound stops, both cranes start completely:

- leaks are controlled inside the dwelling;

- the shut-off valves in the supply sections slowly open slightly.

First, the lower valve is activated, then the air is removed through the Mayevsky valve, then the valve of the upper connection is opened.

Ventilation is completely removed from the riser if the heating in the house is installed according to a system with a bottom filling. This is done in the apartment of the residents of the upper floor.