One of the ways to insulate a house is sheathing with expanded polystyrene. The material is not very expensive, it is quite permissible to carry out the installation on your own. It is possible to protect the cladding from the negative influence of the external environment with the help of a suitable coating. A good option is considered to be facade plaster on expanded polystyrene, which does not require large costs.

Benefits of expanded polystyrene

The material is used for thermal insulation, 98% consists of air. Outwardly, it looks like polystyrene, but in other respects, these heaters are different. Expanded polystyrene plates are widely used for sound insulation and wall insulation.

Main advantages:

- strength;

- moisture resistance;

- high level of thermal insulation;

- vapor permeability;

- there is no reaction with cement, so polystyrene foam boards can be plastered;

- does not contribute to the development of fungi, mold;

- under conditions of correct operation, the service life reaches 30 years.

An outer protective layer of plaster can be laid on the surface of this material.

Types of coatings

In practice, plaster facades with expanded polystyrene can be of several types.

Mineral

They are made on the basis of slaked lime and Portland cement with the addition of stone chips and sand, for example, "bark beetle", "fur coat". They differ from each other only in texture, which is achieved thanks to different types of fractions of pebbles in the filler.

Pros:

- resistance to natural factors: humidity, ultraviolet light, sudden changes in temperature;

- high level of vapor permeability;

- absence of toxic fumes even under the influence of high temperatures;

- good adhesion.

There are mineral-polymer mixtures for external polystyrene plaster. In them, polymer resins are added to the cement base. This slightly increases the price of the composition, at the same time, the elasticity of the coating is significantly improved and the service life is increased.

Acrylic

The basis of the plaster is sand, stone chips, a coloring element, water repellents. Acrylic resins act as a binder.

Decorative plaster on extruded polystyrene foam based on acrylic has the following qualities:

- excellent moisture resistance;

- good elasticity, which eliminates the likelihood of cracking;

- shock resistance;

- a huge selection of shades;

- the possibility of painting facades after finishing finishing;

- high level of adhesion to external coatings;

- aesthetics;

- long service life.

A significant drawback of acrylic coating is its high price.

The dyes that are part of acrylic plasters are unstable to the influence of ultraviolet radiation. For this reason, the color will fade over time.

Characteristics of expanded polystyrene plaster

Facade plaster for expanded polystyrene is in great demand, since it has many positive properties:

- Strength.Due to its qualities, it reliably protects the structure from destructive factors.

- Frost resistance. If you do not pay attention to this indicator, then under the influence of frost, the coating may crack.

- Long service life. Facade plaster on expanded polystyrene can serve up to 15 years.

- Water vapor permeability. The ability to remove condensation prevents damage to the finish and the formation of mold and mildew.

- Ease of installation, maintenance. If desired, the coating can be applied by hand. No special care of the material is required.

Due to the listed properties, the plaster ideally fits on the insulation, performs decorative, protective functions.

Preparation for work

Before plastering expanded polystyrene, you need to purchase the necessary tools and ready-made mixtures.

To cover the walls you will need:

- grater;

- small container for solution preparation;

- mixer or drill with pad;

- construction mesh;

- sandpaper for grouting;

- putty knife;

- level;

- Master OK.

Materials:

- plaster mix;

- primer;

- mixture of decorative coating.

To protect expanded polystyrene, special compounds are produced, on which the result of future work depends, the duration of the use of thermal insulation.

Solution preparation

The mixture is prepared strictly according to the manufacturer's instructions.

A solution from a single manufacturer is used within the same building. Ignoring this rule can reduce the quality of the entire coating.

Calculation of the consumption of universal plaster: from 4 kg / m2 - for fastening a reinforced mesh, up to 6 kg / m2 - for the final leveling of the external walls of the structure.

The mixture should be diluted to a liquid state so that it flows off the spatula.

Styrofoam plaster technology

It is imperative to use an inner mesh to securely fix the flooring. Otherwise, the coating will not last long.

Reinforcing mesh

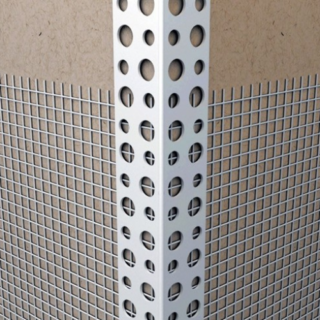

A dense insert is more suitable for working with insulation, since plaster is better placed on it. But in this case, it is more difficult to work with corners. The best option is a mesh with a density of 140-150 g / m2. First of all, they begin to finish the slopes of the room.

The procedure for installing reinforcing material at the corners:

- The mesh is cut into 1-meter strips, which are folded inside.

- A solution is applied to the wall. The area to be covered should correspond to the size of the cut strip.

- Apply reinforcing material to the corner, smooth with a spatula. The latter should move from the top to the bottom, from the central area to the extreme.

Thus, the entire mesh is covered with a layer of plaster.

The installation of reinforcing elements on the walls is performed as follows:

- The mesh is cut into pieces about a meter long. Sequential fastening is done in small pieces, because the mixture dries quickly enough.

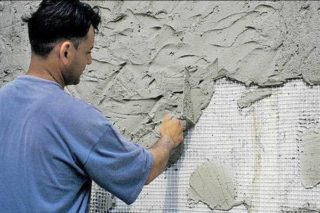

- A solution is applied to the area of one area, on which a piece of mesh is laid out, leveled, fixed with the help of smoothing movements with a spatula.

- In case of incomplete immersion of the reinforcing material, the solution is applied again.

A similar work is gradually done on the following sections of the wall.

Surface grout

The procedure is performed after the walls have dried with sandpaper and a float. After previous work, it can be started after 2-3 hours on warm sunny days, in a day on cloudy days.

Grouting is done in a circle. If wet plaster gets on the paper, it must be replaced.

Alignment

The next stage of work is the application of a leveling layer, surface priming.

- With a small spatula, put the solution on a large one.

- With slow, confident movements, the mixture is applied to the surface of the wall.

- After the applied layer of solution has dried, grout is done (no later than the fourth day after the previous stage of work).

- Treat with an antifungal primer using a roller to prevent mold.

After the primer is dry, you can start decorating.

Decorative plaster

For work outside, there are special mixtures that are resistant to sudden changes in temperature. Their properties depend on the binder, additional elements.

The sequence of decorating plaster:

- A working solution is prepared.

- Apply a layer of plaster (no more than 4 cm). The next one is applied only after the previous one has dried.

- Grouting is performed if the plaster is half dry (fixed, but amenable to correction).

The decorative layer can be applied in the following weather conditions:

- temperature - 10-25 ° С;

- humidity - does not exceed 70%;

- there are no strong gusts of wind.

The special structure of the facade is formed with a specially shaped roller.

Famous brands

Cement plasters for outdoor use must withstand the effects of the external environment, temperature fluctuations. For this reason, frost resistance and strength are especially important for them.

Ceresit

Compressive strength (a characteristic indicating the ability of a material to withstand loads, resist fracture) is 8 MPa. Frost resistance - about one hundred freeze-thaw cycles.

Knauf

Possesses all the properties of Ceresit. The only difference lies in lower compressive strength (7.5 MPa) and frost resistance (75 cycles).

Osnovit

Plaster mixes have high strength - 10 MPa, frost resistance index - 75 cycles. The series contains a variety of types of plasters: winter, reinforced, high-strength.

Plastering expanded polystyrene plates is an excellent way to protect against adverse external influences, to create an attractive appearance of the structure. The technology of plastering on extruded polystyrene foam is quite simple. If desired, it can be easily mastered and performed on your own.