The insulated Finnish foundation (UFF) is more in demand in the domestic market for the construction of low-rise buildings than the Swedish plate. There are many reasons for this, one of them is that a private developer is more accustomed to seeing buildings with a high basement. At the same time, UFF contains some elements of Swedish technology: an insulated base, which attracts with the ability to avoid unnecessary heat loss into the ground.

- Features of the device of the insulated Finnish foundation

- Pros and cons of an engineering solution

- What is the difference from other technologies

- Applicability of technology in practice

- Technological stages of construction of an insulated Finnish slab

- Site marking and earth operations

- Drainage and subbase device

- Organization of the tape monolith

- Work on laying insulation and filling the perimeter inside

- Waterproofing device

- Filling the floor

Features of the device of the insulated Finnish foundation

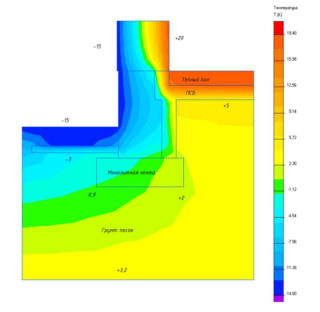

UFF is a construction of the base of a house, in which a strip foundation of a shallow type runs along its perimeter - it is implemented in the form of a monolithic structure made of reinforced concrete or prefabricated from blocks resting on a concrete heel. Inside there is a completely filled plane. The elements are separated by a layer of thermal insulation and are independent from each other. A leveling dump is arranged under the slab, which is also insulated from the screed with extruded polystyrene foam or a similar type of insulation.

Among other things, according to the technology of Finnish engineers, it is envisaged to equip a thermal barrier around the building, laying it under the blind area.

Pros and cons of an engineering solution

The positive qualities of the Finnish development are reflected in the following points:

- Due to the ability to arrange a high base of the tape, there is no need to organize earthworks to deepen and level the base of the soil, especially on a pronounced relief.

- A screed with all utilities can be done after the construction of the box.

- The independence of the tape and the floor allows you to dismantle and repair the latter without the risk of disrupting the supporting structure.

Among the shortcomings in the first place is the complexity of the project and serious financial investments in it. UFF requires a certain professionalism and increased culture of construction work.

What is the difference from other technologies

Compared with other methods, the technology of organizing the UFF can only be compared with the insulated Swedish plate (USHP), which is similar in the principle of construction. The main differences are:

- In the Swedish version, there is only a reinforced perimeter reinforced platform without tape.

- The concrete pouring trough for the USP is extruded polystyrene foam of a special shape with sides.

- In UFF, you can get a higher base, the tape in it is insulated on both sides along the entire perimeter.

- The Swedish technology has a one-piece reinforced frame, while the steel skeleton of the insulated Finnish monolith under the screed and in the tape are not interconnected.

In a financial sense, the arrangement of the UFF can cost more than the Swedish project, but the costs of building the first one can be extended over time.

Applicability of technology in practice

The technical parameters of the standard UFF allow the implementation of this type of foundation in any climatic zones of the Russian Federation. If the weight indicators of the structure being erected are within the normal range (at the rate of 3 tons per linear meter of shallow tape), the Finnish slab can be arranged on soils of any mechanical composition.

It is possible to increase the load on the UFF and erect stone walls with a mass of up to 5 tons per meter instead of frame walls. This will require an increase in the support heel, and for each specific case, it is necessary to calculate the width of the latter.

On average, any one-story houses with light frame-type walls meet the standards of loads on the base of the Finnish-style foundation.

Technological stages of construction of an insulated Finnish slab

The foundation is one of the most critical elements of the structure, therefore, during its construction, certain operational stages are adhered to. The stove, developed by Finnish engineers, due to its complexity, requires strict adherence to the production technology:

- Work on marking and ground planning.

- Organization of the drainage system and waterproofing.

- Filling the strip base.

- Laying of heat-insulating sheets.

- Adding soil under the slab.

- The device is a barrier for moisture and heat transmission under the floor.

- Pouring concrete base screed.

The last three stages from the list do not have to be performed in the first place in the complex of all works on the construction of the building. You can kick out the walls, install a roof, and then prepare a pillow in a weather-protected room and fill the floor.

Site marking and earth operations

It is most convenient to mark the boundaries of the strip foundation with stakes with twine stretched between them. Up to half a meter, they are carried out outside the wall, where the perimeter of the blind area ends. Excavation operations are reduced to the removal of soil (the remaining surface should be free of plant residues) from the trench for the device of the support heel of the tape and drainage.

Drainage and subbase device

In the resulting trench (from the edge of the future concrete heel), a pipe wrapped in geotextile with small holes is laid so that there is a slope towards the drainage of storm water. All this is covered with a layer of gravel 20 centimeters high and slightly compacted. Geotextiles are also placed on top of the rubble.

Drainage when constructing a shallow foundation should be given special attention, since otherwise the base can easily be washed away, and the supporting structure will be destroyed.

Organization of the tape monolith

First of all, a concrete heel with a metal skeleton made of reinforcement inside is poured along the entire perimeter of the building. The width of this support should not be less than 0.6 meters, and the height - 0.3 meters.

Monolithic MZLF on top of the heel must be reinforced with 12 or 14 reinforcement. Therefore, inside the formwork set in level at the height of the plinth, a frame is knitted from a rod. The resulting structure is poured with concrete and allowed to harden and stand.

To make the foundation strong, it is advisable to periodically water it from a watering can, especially on hot days.

Work on laying insulation and filling the perimeter inside

After removing the formwork, the inner part of the basement is insulated with expanded polystyrene sheets (the polymer thickness should not be less than ten centimeters), fastening the latter with umbrella dowels. After that, the entire pit is covered with a geotextile cloth, on top of which a gravel layer is poured, followed by a vibratory rammer.

Waterproofing device

A bituminous waterproofing layer is laid on a gravel pillow, which is simultaneously welded together with a gas burner. There should be at least 3 layers of such a barrier. Also, this material is brought to the basement insulation.On top of this pie, a foam polystyrene insulation with a thickness of ten to twenty centimeters is laid.

Filling the floor

The entire space under the future floor is reinforced with a mesh (you can choose any cell, but no more than 15x15 cm), on which the pipe of the warm floor system is installed. In addition, all communications should also be brought out: electricity, water and sewerage. The screed is poured with concrete.

It is important to fill the floor in one go, avoiding interruptions in time. For this, it is convenient to use the services of trucks with concrete mixers.