Studies of thermal performance indicators and practical measurements show that up to 25% of the heat in a private house is spent on heating the soil. It is uncomfortable to be in rooms with a cold coating. The problem is solved by installing a warm floor on the ground floor on the ground floor. The arrangement is within the power of home craftsmen, but there are nuances that are studied before starting work.

Purpose and features

The composition and characteristics of the soil, hydrological and meteorological conditions in different climatic zones, the requirements for the design of the premises force homeowners to think about arranging concrete floors on the first floor of the house.

Building structure:

- prevents heat loss, saving money on energy costs;

- prevents the penetration of moisture and groundwater into the house, prevents the development of mold and mildew;

- serves as the basis for the topcoat;

- helps to quickly and evenly warm up the entire volume of the room;

- insulates the building from extraneous noise in a low range, emitted by passing vehicles.

The construction of floors on the ground with insulation should be taken responsibly - in case of disturbances in the operation of the heating system, you will have to dismantle the concrete screed, which is an expensive and time-consuming procedure.

In an area with a high level of groundwater, the wrong technology will not allow protecting the building from flooding the first floor.

For a warm floor, a headroom is needed in the room - the thickness of the floor cake on the ground with insulation reaches 35-50 cm.

Having made the decision to make a warm floor, they begin calculations, procurement of materials and tools.

Materials and tools

To equip the rough and final screeds, heat and waterproofing you will need:

- quarry or washed river sand;

- crushed stone or gravel with a fraction size of 20–40 mm;

- heat insulator - extruded or foamed polystyrene foam;

- material for steam and waterproofing;

- reinforcing mesh for finishing screed;

- cement grade from M-300;

- damper tape.

For the heating circuit, pipes made of metal-plastic, copper or cross-linked polypropylene are purchased. You will need a cabinet where distribution and control valves (manifold, taps) are installed. Special fasteners for pipe laying speed up the work.

Before starting work, prepare the tool:

- a concrete mixer or metal sheet for mixing the mortar by hand;

- shovels, buckets, grout;

- tape measure, bubble or laser level;

- drill or hammer drill;

- floor leveling guides - permanent or removable.

For compaction of soil, special devices are purchased or made from wood. Mechanical rammers with petrol or electric motors can be rented.

Prepare a supply of water if there is no centralized water supply on the site.

The calculation of the required materials is carried out based on the geometric dimensions of the building and the thickness of the layers of the "pie".

Layer-by-layer composition of the warm floor

Durability requirements impose special conditions on the arrangement of the base.

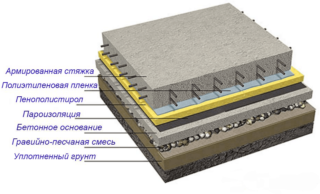

The underfloor heating cake on the ground includes layers:

- prepared soil base;

- sand;

- crushed stone or gravel;

- rough screed;

- waterproofing;

- insulation;

- reinforced finishing screed with pipes poured into it;

- topcoat.

It is important to follow the installation procedure and technology.

Step-by-step instruction

The work on laying a warm water floor consists of the stages of preparing the soil surface, installing the base under a layer with heating pipes, laying and pouring heating elements and finishing the surface.

Preparation of the earth surface

The markings start from the front door. Using a level, draw horizontal lines on the walls - it will be convenient to measure the desired surface height from them when mounting the cake. The horizontalness of the surface is checked after laying each layer.

The surface is leveled over the entire area, removing the soil. The depth of the resulting "pit" should be 30-35 mm.

The layer of earth with organic matter is completely removed - in the process of decomposition of the remnants of vegetation, the floor will sag and the screed may collapse.

If you had to dig too deep, the lack of soil is compensated for with sand.

When groundwater is located close to the surface, a clay castle is made. To do this, greasy clay is soaked in water for 2-3 days. In the process, the readiness of the material is checked. The mass compressed in a fist should not disintegrate. The clay is well crushed and laid in a layer of 5–10 cm. The layer is tamped. After drying, they begin to arrange a rough screed under a warm floor on the ground.

Installation of a drainage system can be an effective solution for areas with high groundwater.

Installation of a rough screed

A layer of sand 5–7 cm thick is poured onto the prepared base. The surface is spilled with water and tamped. Use a device made of a block of wood with handles or a power tool.

The next layer, 30-50 mm thick, is made of gravel. The material is compacted and rammed in the same way as sand.

If expanded clay is cheaper than crushed stone in the construction region, it is better to choose this material for backfilling - it will provide additional thermal insulation.

For a rough screed, a cement-sand mixture of class B7.5-B10 is used. These indicators roughly correspond to the grades of concrete M100 – M150. To obtain a mixture with the specified strength indicators, cement and sand are mixed. The proportions are shown in the table.

| Solution grade | Cement grade | Proportion of cement: sand |

| M100 | 300 | 1:3,4 |

| 400 | 1:4,3 | |

| 500 | 1:5,3 | |

| M150 | 300 | 1:2,6 |

| 400 | 1:3,25 | |

| 500 | 1:3,9 |

To maintain the level, beacons are installed on top of the rubble. Depending on experience with concrete and the speed at which the mortar is prepared? the distance between the beacons is chosen from 100 to 200 mm. Filling is carried out in stripes.

The subfloor should not have strong contact with the walls. Before pouring, a damping belt is mounted around the entire perimeter of the room. If no gap is left, the screed may collapse from expansion during temperature fluctuations.

The finished subfloor is periodically watered for 2 days. The humidification intervals depend on the temperature and humidity of the air - it is important not to allow the mixture to dry completely. If the surface is left without moisture? cracks will appear in the concrete, reducing the strength of the structure. In addition, the waterproofing capacity of the screed will be lost.

Concrete gains full strength within 28 days, but work on the further construction of the warm floor can be started in 7-10 days, when the surface is dry.

Waterproofing and insulation

Waterproofing is laid on top of the rough screed. A thick polyethylene film, geotextile or roofing material is suitable as a material.The layer is placed with an approach to the walls to a height of 10-15 cm. After all work is completed, the excess is cut off with a knife. The purpose of waterproofing is to prevent the penetration of groundwater into the room through the floor. Modern materials allow waterproofing. by coating or gluing roll materials.

Insulate the floor with expanded polystyrene. Extruded polystyrene is sold in the form of plates with shaped ends. This allows you to lay the insulation tightly, without gaps. Polyfoam, or expanded polystyrene foam, is produced in the form of plates with smooth edges. Joints and seams are sealed with polyurethane foam. According to their characteristics, the materials are very similar, but the price of extruded polystyrene is one and a half times more expensive. For floor insulation, foam plastic with a density of at least 25 kg / m3 is chosen - this characteristic will allow you to walk carefully on the surface without damaging the coating. Foam grades with a density below the specified are intended for wall insulation, they are easily destroyed by stress when walking or under the weight of a screed. The thickness of the insulation is 50–100 mm, depending on the climatic zone.

It is advisable to lay foil-clad material on top of the insulation layer before installing the pipes - this will reduce the outflow of heat from the inside of the room into the ground.

Pipe laying

A reinforcing steel mesh is placed on top of the insulation. For laying, spacers are used, which will leave a gap between the thermal insulation and the mesh. Wire thickness from 3 mm, mesh size 50x50 mm.

Pipes are attached to mesh cells or guides are mounted in a rough screed with special anchors.

When laying out, they are guided by the general rules:

- along the walls, the distance between the pipes is less than in the center of the room;

- the maximum loop length for pipes with a diameter of 16 mm is 100 m, for a diameter of 20 mm - 120 m.

- all sections must be intact, without joints;

- the ends of the pipes are led out into the control cabinet;

- the collector must be located at the highest point of the circuits;

After installation, a trial run of the heating system and pressure testing are carried out. Revealed leaks are eliminated, and the circuit is replaced if necessary. The finishing screed is poured after the coolant has completely cooled down.

The concrete grade is M150. To simplify the work, plasticizing additives are added to the composition, which improve the adhesion of the solution to the reinforcement mesh and the surface of the pipes and simplify the leveling of the mixture. Be sure to install a damper gasket around the perimeter of the room. In the places where the pipes exit into the control cabinet, they are pasted over with the same damper material.

In rooms where high quality surface preparation is required, a "self-leveling floor" is used. The finished mixture is diluted with water according to the instructions and poured over the finishing screed. In this way, a perfectly flat horizontal surface is achieved.

A full start of the heating system is carried out after 28 days, if the final screed was made on the basis of cement mixtures. The same period is maintained after laying ceramic tiles on the floor.

Topcoat options

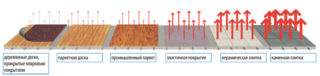

Floor coverings can be used as a final finish:

- laminate;

- linoleum;

- parquet board;

- porcelain stoneware or tiles.

It should be borne in mind that each of the materials has an individual thermal conductivity. The fastest way after starting the boiler will warm up the tiled floor, and worst of all, the laminate will let the heat through.

Linoleum on a pile lining is not used for underfloor heating - the room will warm up for a long time, and it is difficult for heat to penetrate into the room through insulation.

Equipping underfloor heating on the ground is a time-consuming process that can be performed independently, having the skills of general construction work. If necessary and if they are not confident in their own abilities, they turn to specialized organizations. The effort, time and money spent are paid off by saving on payment for energy carriers and comfortable conditions in the house.