When creating or reconstructing a home pipeline, it is worth considering the quality of heating, the efficiency of the heat carrier consumption and the cost of utility bills during the heating season. To choose pipes for heating, it is necessary to take into account the power of the boiler, the total load on communications, material and technical parameters of the products.

- The main criteria for the selection of pipes for heating

- Material characteristics

- Varieties of heating pipe materials

- Features of the metal pipeline

- Specificity of products made of composite polymers

- Reinforced-plastic pipes

- Pros and cons of steel and copper pipes

- Features of steel pipeline

- Features of copper piping

- Polymer and metal-plastic type of fittings

- Characteristics of polymer reinforcement

- XLPE piping

- Features of metal-plastic reinforcement

- Which pipes to choose

- Size selection rules

- The specifics of installing heating pipes in a private house

- Execution of a one-pipe scheme

- Implementation of a two-pipe scheme

The main criteria for the selection of pipes for heating

It is not possible to select universal tubular products. If the system is just being designed or it is planned to replace an outdated highway, it is worth paying attention to the following factors:

- pipe section parameters;

- boiler power indicator and type of fuel;

- the general square of the heated premises;

- type of laying - it is equipped in an open and closed way;

- features of creating a contour - you can perform an external or open arrangement, install it in the floor or walls, bring it to a radiator;

- the presence of a pump for forced movement of the coolant;

- temperature indicators of a separate section of the circuit;

- pressure in the system - in the centralized system of a multi-storey building reaches 16 atm., in an individual private - up to 2-3 atm.

Consider the presence of unheated rooms and the maintainability of the line.

Material characteristics

In a private house or a country cottage, a pipeline made of metal (black, copper, stainless steel) or plastic (polypropylene, cross-linked polyethylene, metal-plastic) is advisable. To compare the operational characteristics of pipes intended for heating communications, it is worth referring to the table:

| Material | Working temperature, ° С | Roughness, mm | Pressure loss probability, hPa / m | Linear expansion coefficient, mm / m * deg. |

| steel | 130 | 0,07 | 5 | 0,012 |

| metal-plastic | 95 | 0,004 | 1,5 | 0,025-0,03 |

| polyethylene | 90 | 0,007 | 1,8 | 0,15-0,17 |

| polypropylene | 70 | 0,01 | 2 | 0,15-0,17 |

Metal products can withstand high loads, but inside the house it is better to use options that can withstand hot water temperatures.

Varieties of heating pipe materials

The performance of the system, the method of its installation and the possibility of independent calculation of heat loss depend on the type of material. Manufacturers produce metal and polymer pipes.

Features of the metal pipeline

For the manufacture of pipes, black, stainless or galvanized type of steel is used. This metal is durable and resistant to mechanical stress. The operating temperature of the line is 130 degrees, and the maximum pressure is 30 atm. Steel does not ignite if there is a hot coolant inside.

The disadvantages of black and galvanized pipelines are heavy weight, difficulty in self-assembly, high heat loss and roughness of the inner layer, where deposits can accumulate. All types of metal, with the exception of stainless steel, must be painted.

The metal type of pipes without an anti-corrosion layer has been in operation for 15 years, with a special coating - up to 50 years.

Specificity of products made of composite polymers

Polymers are polyethylene, polypropylene and metal-plastic. These pipes are best used for heating a private house due to their long-term operation - about 30 years. A coolant with a temperature of 95 degrees can circulate through the system.

Composite polymers are distinguished by their plasticity, which excludes cutting of the route, the number of fittings. Plastic does not corrode, so you can make hidden installation in the wall or arrange a warm floor. It is necessary to select the wall thickness (from 1.8 to 3 mm) according to the level of the circuit pressure.

The disadvantage of composites is deformation during overheating, rupture when the coolant freezes. Due to the smoothness of the inner walls, deposits do not form on the pipes.

The contour of modifications with an anti-diffusion layer is not airborne.

Reinforced-plastic pipes

The products are distinguished by an attractive appearance and a variety of diameters - from 16 to 63 mm. The walls of the fittings are 2-3 mm thick, the permissible long-term temperature of the coolant is 95 degrees, the short-term temperature is 110 degrees.

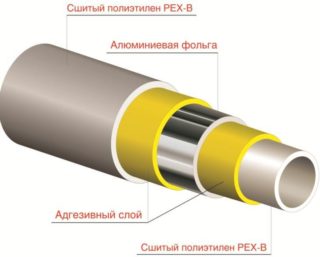

The construction is multilayer, which allows the line to withstand heavy loads. A standard reinforced plastic pipe consists of the following elements:

- outer layer - cross-linked polyethylene, resistant to temperature, shock and chemical influences;

- sizing - needed to bond materials;

- reinforcement - flexible and durable aluminum is used;

- inner layer - smooth cross-linked polyethylene.

The reinforced layer can be up to 190-300 microns in thickness, which allows it to withstand pressures up to 8 kPa.

The track is connected by pressing with fittings or collets using a special key. The docking method is selected by the owner or the on-site installer. The material is flexible, which makes it easy to self-install with a pipe bender.

The bend of a metal-plastic pipe is formed manually, with an optimal radius of 80-125 mm.

Pros and cons of steel and copper pipes

Features of steel pipeline

Until the end of the twentieth century, a steel pipe was the only way to equip heating. Currently, the owners of private houses prefer to make communications from carbon steel.

The material has several advantages:

- resistance to water hammer, temperature and pressure fluctuations;

- excellent indicators of strength and resistance to mechanical stress;

- minimum expansion coefficient excluding expansion joints;

- good thermal conductivity;

- inexpensive material price even when buying consumables.

The steel type of communications has a number of disadvantages:

- minimal resistance to corrosion;

- the roughness of the walls, as a result of which deposits are formed;

- risks of corrosion due to leaks;

- heavy weight;

- the need for welding skills and special equipment for installation;

- painstaking thread cutting when threaded connection;

- the transmission of stray currents by iron.

Galvanized models are practically non-corrosive.

Features of copper piping

The copper battery and similar fittings are still used today in private homes. The reasons for their use are:

- durability - metal material does not deteriorate for 100 years;

- high indicators of tightness, corrosion resistance;

- no deposits inside;

- high thermal conductivity;

- operating temperature range from -200 to +500 degrees;

- resistance to pressure drops.

The disadvantage of copper piping is the high cost of the material itself.

Copper pipes cannot be combined with unalloyed steel products - they will rust quickly.

Polymer and metal-plastic type of fittings

Characteristics of polymer reinforcement

Modern PP pipes are made from a non-toxic synthetic polymer. They are distinguished by impact resistance, the possibility of repeated bending, wear resistance and dielectric properties. PVC pipes used for heating can withstand pressures up to 25 bar at temperatures from 0 to +25 degrees and 10 bar with short-term heating (from 70 degrees and above).

The polymer type of reinforcement has several advantages:

- versatility - an apartment, production area or a private house is equipped with such a highway;

- ease of installation with your own hands in the presence of a boiler with a maximum heating of the coolant up to 70 degrees;

- minimum costs for components;

- the smoothness of the inner surface, where deposits do not accumulate;

- using simple installation tools;

- long period of operation - almost 25 years;

- beautiful appearance of the track;

- resistance to low temperatures.

The plastic type of pipes is characterized by low rigidity, as a result of which the lines can sag, crack and break.

The efficiency index of the home system depends on the reinforcement of the PP pipe. Manufacturers use several types of reinforcing material:

- Foiling - sealing is done outside, in the middle and inside with non-continuous, corrugated and solid sheets. The foil prevents expansion when heated.

- Fiberglass layer - Placed in the middle of the pipe by coextrusion. Fiberglass when welding the fittings creates a strong bond that does not delaminate.

- Composite mixtures - compositions are used in which polypropylene is mixed with fiberglass. The pipes receive additional strength and resistance to mechanical stress.

Fiberglass reinforcement is the best option for home construction.

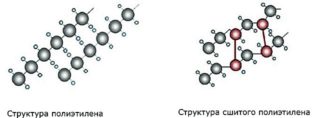

XLPE piping

- good shrinkage performance;

- retention of shape at the level of the connection even when the temperature rises to 200 degrees;

- wear resistance and preservation of integrity under high pressure conditions;

- low thermal expansion coefficient;

- the possibility of laying in a hidden way;

- the ability of fragments to memorize the position in the system.

The polyethylene type of pipeline is destroyed by ultraviolet radiation.

Features of metal-plastic reinforcement

For production, plastic and an aluminum foil frame with an adhesive bond are used. The fittings are suitable for rooms with constant heating. It is connected using fittings - detachable and one-piece. The threaded coupling should only be carried out by a specialist.

The metal-polymer type of the system has the following properties:

- resistance to corrosion - only the plastic layer comes into contact with the coolant;

- smoothness of the inner surface where plaque does not accumulate;

- tightness, which is preserved by foiling;

- good flexibility - convenient for rooms of any configuration;

- sale in bays of 50-500 m, which eliminates overpayments per meter of material, reduces the number of rations;

- service life - up to 50 years;

- low coefficient of linear expansion - the pipeline can be installed in the wall.

The material is not resistant to UV rays, therefore it fits into a corrugated pipe.

Which pipes to choose

Polypropylene is characterized by high tightness, ease of self-connection and low weight. There is no pressure on the supporting systems and the smoothness of the walls prevents the formation of deposits. The stiffness of the material involves using fittings to create the turn.If one area fails, a complete system change is required.

Metal-plastic is reliable, it is distinguished by the simplicity of the independent organization of the highway. You can connect the products with a wrench, but the soldering points can be damaged. Metal-plastic fittings are justified if you need to heat the house in a constant mode.

If you have financial resources, it is worth stopping the choice on a stainless line with a service life of up to 100 years.

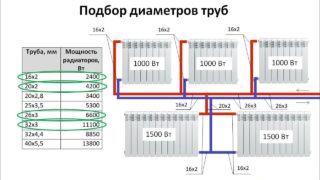

Size selection rules

The pipe sizes depend on the quadrature of the heated area:

- the optimal diameter for crowded places is 200 mm;

- in small houses, products 20-30 mm in diameter are suitable;

- in the presence of hot water supply, a 25 mm pipe is put on the risers, the rest of the sections are made of 20 mm pipes;

- central heating is made of fittings 25 mm in diameter;

- for a warm floor, constructions with a diameter of 16 mm or more are suitable.

For an accurate calculation of the parameters, you should contact a professional or use an online calculator.

The specifics of installing heating pipes in a private house

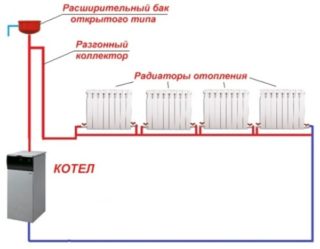

A single-pipe or two-pipe heating system can be used in a private house.

Execution of a one-pipe scheme

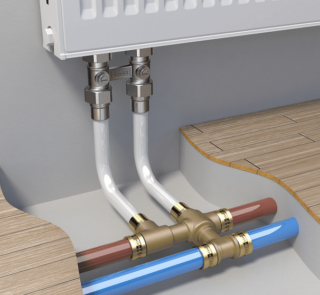

The principle of arranging communications is to connect all radiators to one collector. The device will work for supply and return, and the coolant will move through the batteries in the form of a closed ring.

When organizing a one-pipe scheme, the radiators cool down faster, so you will need to add sections. The collector diameter must be larger than the pipe size.

The scheme is implemented in several ways:

- Leningradka, or horizontal - up to 5 radiators are used. A larger number of elements will not allow the last to warm up normally. Communications are suitable for a small or country house.

- Vertical - you will need one-pipe vertical risers. The design is justified in a two-story house.

The batteries of a one-pipe system act on each other, so it is problematic to connect the automation.

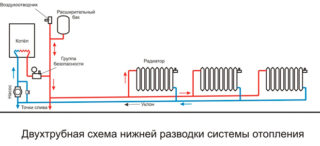

Implementation of a two-pipe scheme

The trunk can be connected in several ways:

- Dead-end - the entire network is divided into several arms (branches). The heat carrier moves towards the pipes.

- Passing - the return collector continues to supply. The coolant has one direction, which is closed in the form of a ring.

- Collector, or radial - wiring provides for the supply of a separate pipe from the collector to the radiator. The highway is hidden under the floor.

When laying large pipes with a slope of 3-5 mm / 1 m, gravity operation of the system is possible.

The selection of heating pipes should be carried out depending on the materials, the possibility of permanent residence in the house. Manufacturers produce several types of products that differ in cost and installation complexity.

At 60 degrees, zinc begins to flake off

more than 25 years of work experience for a private house, the best system in my experience is metal pipes pipes, since they have the highest heat output at minimal cost, especially in the private sector where individual heating is used

Many generations have grown up in log houses and they deservedly enjoy great popularity. Despite the intensive development of construction technologies, most private and country houses are built of wood. In the conditions of the far north - a well-built, properly insulated house, with a well-folded stove, is the only way of living in the countryside.