Underfloor heating cannot be used with all types of coatings. This is due to high temperature and humidity, which can deform the material. The parquet board is made of wood that is susceptible to moisture. For this reason, the rules for installation work must be followed.

Compatibility problems of parquet and underfloor heating

Parquet board is a good natural insulator that effectively protects from cold weather without the use of additional insulation materials. But in the case of additional floor heating, difficulties can arise. They are due to the following factors:

- Hypersensitivity to moisture and temperature. Exceeding the accepted standard can lead to deformation of the coating and the appearance of cracks.

- Installation of parquet boards for underfloor heating is carried out on self-tapping screws. These fasteners can damage the pipes carrying the heating medium, electrical cable or thermal film. Violation of the integrity of these parts can lead to failure of the entire system.

To avoid these problems, you need to choose the right materials for the warm floor and do the installation according to the instructions.

Device recommendations

In the case of using decorative parquet, certain recommendations must be followed in order to guarantee the effectiveness of the underfloor heating without deformations and damage to the coating.

- Do not use maple or oak parquet under floor heating. These types of wood are deformed at the slightest change in temperature.

- The optimum thickness of parquet boards is 12-15 mm. If a thinner material is used, the risk of fracture increases and the strength of the material deteriorates. Thicker boards do not transmit heat well, which makes the floor ineffective.

- Floating installation should be done. Thanks to this method, during thermal changes, movements of the structure will be carried out, which will protect the material from destruction.

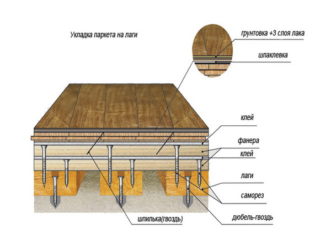

- Underlay plywood must be fixed to the concrete base using a two-component polyurethane adhesive. To additionally fix the structure, self-tapping screws are used. First, you need to make a markup for their attachment.

- A layer of thermal insulation is placed on the surface of the plywood under the parquet. It reduces the temperature effect on the board, but at the same time impairs the heating effect. The layer thickness should be kept to a minimum.

- The maximum heating temperature of the bottom layer of parquet should not exceed 40 ° C. With such values in the room on the surface of the floor covering, there will be a comfortable temperature regime of 27-28 ° C.

- Wooden planks are attached to metal brackets. Thanks to them, you can make a connection without installing additional mechanisms. Also, this method allows you to naturally regulate the contraction and expansion of the board during temperature fluctuations.

- Uniform heating of the entire surface of the floor covering must be ensured.

Strict adherence to the installation instructions will allow the warm floor to function for the stated period and not harm the parquet flooring.

Underfloor heating options for parquet

There are several types of underfloor heating: water, thermal film and cable.In each design, the installation of parquet flooring will have its own characteristics.

Water heating

This type of floor heating is one of the most common. It implies the installation of pipes through which the coolant moves - hot water. Thermal energy is obtained from the existing heating system or from various boilers.

In the case of a water floor, the heating circuit is laid with a snake, snail or other method. To fix the pipes, plastic ties are used, which are pre-attached to the reinforcing mesh.

There are modern options for arranging underfloor heating, which involve the use of an insulating substrate. This design has special protrusions in which pipelines are laid.

The water floor has an important drawback - the pipes must be laid in a thick layer of cement screed. The structure will be heavy, in case of breakdown it will be impossible to repair it.

It is important to test the pipes and check their functionality before pouring. The heating circuit must be made from a single piece of pipes without the use of connecting elements.

Films

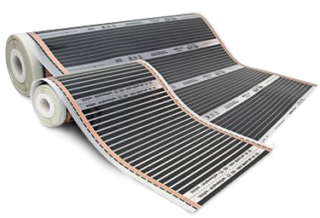

Infrared underfloor heating is a modern solution for home heating. Has many advantages over other systems. When laying, the use of a cement-sand screed is not required, due to which a thin structure will be formed with minimal labor costs.

Installation of heating elements is carried out on a thin heat-insulating substrate with a foil coating. All elements should be connected in parallel with each other. Control of the main temperature characteristics is carried out using a thermostat.

The main advantages include:

- Flexibility. It can be laid on non-standard surfaces - podiums, ledges, steps.

- Ease of assembly and disassembly without changing characteristics. The absence of a concrete screed will make it possible to repair failed elements without destroying the entire system.

- In the event of a breakdown of one of the sections, the entire system will continue to heat the room.

- Long service life.

- High heating rate. The boards heat up in about 10 minutes.

- Energy saving.

- Safety for human health.

The disadvantages include the high cost of the floor.

Cable system

A single-core or two-core cable is a heating element. They are placed on an insulating substrate. Fixation is carried out by means of special fasteners according to a certain scheme, the distance between which depends on the performance characteristics of the floor heating.

Also available as heating mats. Their construction consists of a mesh on which cables are laid. It is easier to install with mats, since calculations of the distance between the turns of the heating elements are not required. A mandatory device in the system is a thermostat. It controls and modifies the parameters of the system to create a comfortable room temperature.

Such heaters are enclosed in a screed layer. After that, the parquet board is installed.

The cable system is the most energy consuming. During operation, the payment for electrical energy will increase.

Installation of underfloor heating under parquet

When using a water-heated floor, the parquet laying algorithm is as follows:

- Installation of insulation on a concrete base. There should be a heat-reflecting foil on one side.

- Laying pipes with a spiral or snake.

- Pouring a cement-sand screed.

- Plywood is attached 28 days after curing.

- Parquet is laid on a warm water floor.

This method is notable for the complexity of the work, so you need to entrust the installation to a specialist.

Installation when using a cable floor:

- Preparation of the concrete base. It is necessary to remove the old coating and clean the surface.

- Installation of thermal insulation.

- Laying cables.

- Pouring cement-sand mortar.

- Parquet laying after the screed has completely dried and strengthened.

Stages of laying a film IR floor:

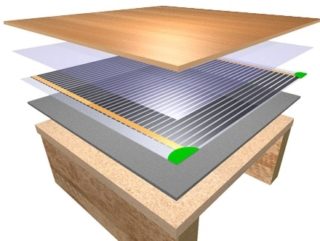

- Preparation of the base. It can be concrete or wood.

- Laying waterproofing.

- Insulation laying.

- Laying of infrared film, which is fixed to construction tape.

- Laying plywood to create the base.

- Installation of parquet boards.

It is also necessary to install a temperature controller.

The infrared system, due to its characteristics, is the best option in combination with parquet. Despite the ease of installation, the parquet should be laid by a master who has experience working with such systems.