Tile flooring is carried out in rooms with high humidity and high traffic. Typically, this cladding option is chosen for the kitchen, bathroom, corridor and balcony. In summer, walking on such a surface is pleasant and comfortable. However, in the cold season, the substrate gets cold and the fabric flooring is not the best solution in terms of aesthetics. Laying underfloor heating under tiles is the best way out of this situation both for a private house and for an apartment in a high-rise. Even an inexperienced master can do this work. The main thing is to choose the right material and observe the technology of its installation.

Pros and cons of underfloor heating under the tiles

Installation of heating elements under the tiles, like any technical solution, has its pros and cons. They must be taken into account before making a responsible choice in favor of their installation.

Underfloor heating under tiles gives the following advantages:

- Uniform heating of the surface. Providing comfortable movement on warm material without socks and slippers.

- Maintaining a comfortable temperature in the room. Underfloor heaters can be used as auxiliary or independent heating.

- Prevention of the development of fungus and mold. In a healthy environment, people will only look prettier, forgetting about allergies and infectious diseases.

When deciding which floor heater to choose, you need to remember about the disadvantages of such devices:

- High energy consumption. This applies to both water and electrical products. Even using the elements as auxiliary heating can seriously impact the family budget.

- Increasing the load on the floor slab. In addition, the use of a cement screed leads to a rise in the floor level by 5-10 cm. The exception is film elements, which can be placed under parquet or covered with tile glue.

- The risk of an emergency. The use of electricity in wet currents is fraught with danger. The water circuit or shut-off valves can be depressurized, and this is fraught with flooding of the lower levels.

Nevertheless, warm floors have long ceased to be an attribute of luxury.

Which warm floor to choose

Modern technologies provide consumers with a wide range of heating appliances and devices that can be placed under ceramic tiles. You need to choose products taking into account the characteristics of the property.

Electric

On sale are products made in the form of cables and mats.

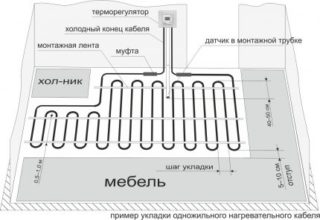

Heating cables are 8-15 mm thick and made of 1 or 2 cores. Depending on the diameter, the wire has a minimum turning radius that cannot be reduced. Installation is carried out with a snake with an indent from the walls by 10-15 cm. After fixing, the structure is poured with a cement screed and tiled. Such an electric underfloor heating for tiles is mainly used in new buildings without finishing and during major repairs, when it is necessary to level the base plate.

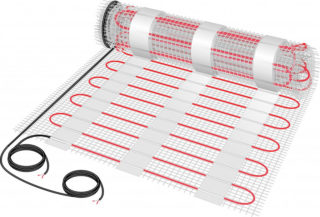

Mats are more popular despite their high cost. This is due to their low thickness and high efficiency.The finished product is a thin heating wire fused into a heat-resistant polymer mesh. The thickness of the canvas does not exceed 3 mm, which makes it possible to lay the tiles directly on the mats, without pouring the screed. Due to the close arrangement of the conductors, a more efficient heating of the surface is provided.

Electricity consumption for cable and matte products is 120-300 W / m² with a service life of 10-15 years.

Water

In terms of energy consumption, the water floor is the most economical, but it has restrictions on the place of installation. It is forbidden to make such systems in apartments of multi-storey buildings, except for the first floors. This is due to the risk of leaks and the large weight of the screed, with which the contours are filled.

Water systems are made of continuous polymer pipes, metal and polypropylene sections. The connection is made to a heating riser or heated towel rail. The disadvantage of such devices is the dependence on the schedule of heat supply by utilities. Another disadvantage is the complexity of arranging the system with shut-off and control valves. To set the optimal temperature and maintain uniform pressure in the circuits, the installation of a mixer, a manifold and a shut-off valve is required. Together with the thickness of the screed, this makes many property owners refuse this option for heating their homes.

Infrared

The infrared floor is a polymer film 0.3-0.5 mm thick with carbon-coated wires located inside. Products are produced in the form of plates 50 × 50 cm. Under the influence of current, the elements emit infrared radiation, which has a heating effect. The advantage of such elements is that they can be placed not only under the tiles. After covering the heaters with a damper cloth, laminate, parquet, massive and engineered boards can be laid on it.

Preparation of the base

Correct installation of underfloor heating requires preparatory work carried out in the following sequence:

- Drawing up a diagram, calculating the need for materials and tools.

- Removal of old cladding, surface inspection, removal of unstable elements, sealing of cracks.

- Treatment of the slab with deep penetration impregnation.

- Pouring a light leveling screed if there is a sag of more than 10 mm.

- Thermal insulation of the base using foamed foam. This is a good insulation up to 12 mm thick.

- Installation of a damper tape around the perimeter of the room.

- Laying and fixing on the base of a metal mesh on which the cable line, matte sheets or water line will be attached.

- Drilling recesses in the walls for fixing the control equipment. After that, you can install a temperature switch, thermostat and other devices.

If electrical devices are installed, it is necessary to consider the issue of connecting a cable to them from the junction box. To do this, you need to make a strobe in the wall, into which a corrugated plastic tube with an exhaust cable is walled up.

Laying technology

Do-it-yourself installation of a warm floor under the tiles is done in accordance with the manufacturer's instructions. The technique differs depending on the type of heating system.

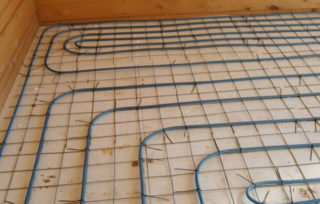

The water circuit can be laid between self-tapping screws screwed into the floor or in foam blocks with channels under the tube. After placing the line, its ends are rigidly attached to the manifold pipes connected to the mixer. The performance check is carried out under working pressure for 2-3 hours. Only then can the screed be poured. It is allowed to use the premises after the concrete has completely hardened.

The heating cable is attached to a pre-laid metal mesh, which also serves as a frame. Fixation is carried out with plastic ties, allowing you to do the job quickly and safely.During installation, the distance between the turns must be observed to ensure an even distribution of heat. After making sure that the cable is securely fastened, you can pour the tie. Its level must be at least 10 mm above the level of the heating elements.

It is better to fasten the mats to the base with staples or self-tapping screws with wide caps. Another option is to glue the plastic mesh directly. After that, bypassing the stage of filling the screed, the tiles are laid. The meshes in the net provide good contact with the substrate.

The infrared film is attached to the base with construction tape. Mechanical fixation should not be used, so as not to violate the integrity of the film. After fixing it, the finishing coat is laid: ceramic, polymer or stone tiles. The solution should be selected taking into account that the film surface has very poor adhesion.

How much warm floor is heated under the tiles

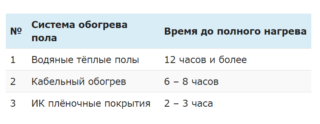

The quality of surface heating depends on the type of system installed and the material applied to it. The water circuit is inert, but retains heat longer due to the energy stored in the pipes and cement screed. Electric heaters heat up faster, but also cool down quickly. The film reaches the set temperature and loses it almost instantly.

The average floor heating time is:

- water circuits - 10-15 minutes;

- e-mail cables - 7-8 min;

- mats - 4-5 minutes;

- IR film - less than 1 min.

This consumes approximately the same amount of energy.

Manufacturers rating

In the ranking of the 10 most famous domestic and foreign manufacturers of underfloor heating, the following companies are leading:

- DEVI.

- Nexans.

- Ensto.

- Hemstedt.

- Profi Therm.

- Extherm.

- Fenix.

- Woks.

- RATEY.

- Teplolux.

The products are distinguished by high efficiency, reliability, safety and long service life. All equipment is adapted to the conditions of Russian housing and the parameters of the current flowing into it.