During the construction of a house or renovation, insulation is often used under the floor screed. It allows you to significantly reduce the percentage of heat loss during the heating season. Different materials can be used for this technology. It all depends on the characteristics of the future flooring.

Requirements for heaters

Before using one or another version of thermal insulation, it is necessary to take into account some operational characteristics, as well as the permissibility of using the material for the screed device.

- Any type of insulation at the time of installation and during its service life must maintain the shape specified by the manufacturer.

- The material should be as environmentally friendly and safe as possible. Once fixed under the screed, it should not emit unpleasant odors.

- Good vapor permeability will provide moisture to the outside, respectively, the material will not get wet.

- The dense structure will make it possible to create a sufficient level of thermal and noise insulation.

Each of the materials has individual requirements for installation, differs in its own characteristics, which are permissible for use in a particular case.

Screed insulation materials

In order to properly organize the insulation, it is necessary to choose the appropriate raw material option.

Styrofoam and styrofoam

You can create an optimal level of thermal insulation at home using foam or expanded polystyrene. These materials have a relatively elastic structure. They are laid in slabs, having previously selected the desired thickness. This raw material contains 96% air, therefore it is considered natural. Thanks to this material, it is possible to minimize the heat transfer rates under the concrete screed in the house and in the apartment. The main advantage of the canvas is its versatility.

Expanded clay

Foil insulation for concrete screed

The foil fabric consists of two layers. The first plays the role of a base and substrate, the second is a reflector. Such insulation is usually based on expanded polyethylene under the screed or polystyrene. It comes in white or blue. It is laid under concrete and has good reflective properties. The product with foil retains heat well and also prevents moisture penetration.

Mineral wool for concrete

This insulation under the screed is considered inconvenient for installation on concrete floor slabs. It is quite difficult to properly lay it and isolate it from moisture. Raw materials require special surface preparation, in particular, laying a vapor barrier film. A special waterproofing material is also laid on top of the insulation before pouring concrete.If this is not done, the interior equipment of the floor will not fulfill its function.

Polystyrene boards

They are a kind of foam. You can fix the insulation on the floor under the screed using special glue or cement mortar. It is also allowed to make a floating insulation cushion. This material has good deformation resistance and excellent moisture resistance.

Polystyrene boards are capable of retaining up to 93% of the heat in a room. The option is acceptable for insulating a private house or apartment.

Rough screed waterproofing

Rough screed is found mainly in their own homes. It is the pouring of concrete directly onto the ground. Also, this design is optimal for arranging a yard or garage structure.

After the stage of filling the screed, waterproofing should be performed in order to completely eliminate the formation of condensation from the soil. It is mounted using special roll insulators - usually a bituminous sheet or membrane films.

The insulating layer must be applied to adjacent walls approximately 10-15 cm. To remove the excess layer, sand the surface must be performed.

If it is not possible to lay the waterproofing material on the ground in front of the concrete screed, first fill in a small layer of the monolith. After solidification, a layer of bituminous material or roofing material is applied.

Options for floor insulation under the screed

There are several options for installing insulation under a concrete screed. Each of them is applied in individual cases.

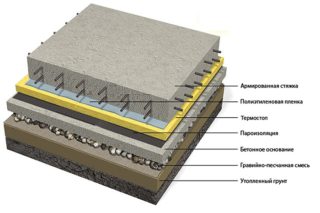

- Floor slab. In such designs, it is advisable to use a standard film, which is laid in two layers. This makes it possible to achieve an insulation thickness of 300 microns. Fused bitumen is also used. However, it is not very practical, as it retains all the unevenness of the concrete screed.

- In the basement level. There is usually a basement, garage or cellar under the floor slab. In this case, thermal insulation is made from materials that are not subject to moisture absorption (styrene foam, polystyrene and others).

- Between floors. So that no heat loss is observed in the apartments during the heating season, thermal insulation is performed between floors in layers of concrete screed. For such structures, expanded clay, basalt wool or expanded polystyrene are considered the best options.

Liquid insulation in apartment buildings is practically not used as thermal insulation. It is rational to use it in partitions where pipelines pass, subject to the presence of another insulation.

Installation tips

To properly lay the insulation on the floor on the screed, you need to follow some simple guidelines. Every nuance can be decisive in the installation process.

- When screed is made, a gap of 1-3 cm should be left between the wall and the floor.

- Without waterproofing, thermal insulation for a concrete screed is not made.

- It is important to follow the sequence of work when organizing thermal insulation.

- The floor cake should have at least five layers.

Upon completion of the installation of thermal insulation for a concrete floor screed, professionals recommend additionally installing insulation reinforcement.