Installation of a metal bath stove will help save time on the construction of a stone structure and reduce financial costs. It is necessary to think over the area where the system will be installed at the design stage, taking into account fire safety, dimensions and weight of the product. Self-installation of a stove in a bath also provides for the organization of a chimney, water supply systems, drainage and a place for a water tank.

- Step-by-step algorithm for installing a bath stove

- Features of the choice of location

- The nuances of preparing the foundation

- Preparatory work for the walls

- Assembling the heating device

- First fire

- Chimney installation

- The process of self-installation of a wood-burning stove in a bath

- Installation of a stove structure on a wooden floor

- Installation of modifications with a remote firebox

- Installation rules for electric furnaces

- Extinguishing media and personal safety

Step-by-step algorithm for installing a bath stove

Before starting installation work, it is required to draw up a project taking into account the fire safety of the structure. You will need:

- pick up non-combustible finishing materials;

- choose a cladding for wooden buildings - thermal insulation and steel sheet;

- leave a gap of 110-125 cm between the stove body and the wall surface;

- lay the thermal insulation covering so that 50-80 cm remains.

Supporting structures, shelves and partitions are placed 110 cm from the stove.

Features of the choice of location

It is worth installing a ready-made stove in a sauna or bath so that the heating of the dressing room and steam room is of high quality, and the operation is comfortable. At the same time, a person must freely move around the steam room.

You can put a heating device:

- In the steam room. The owner controls the fuel combustion process, can put it on. The disadvantage of this zone is the cost of arranging ventilation and the presence in the room of a place for firewood. For year-round use of the bath, you will need a second stove.

- In the dressing room or bath. The unit will heat two rooms and the steam room will be larger. A good ventilation system is organized for the dressing room.

- With the removal of the firebox towards the street. The stove will not burn oxygen, but it will not be possible to control the combustion from the room. Under the remote firebox, you will need to demolish the wall, make a non-combustible portal.

After choosing a place, you will need to refer to SNiP 41-01-2003, which indicates the location of the furnace relative to all areas of the room:

- between the steel body and the wall - 38 cm;

- from the unit to the wooden wall - 50 cm;

- from the point of outlet of the fuel channel to the door - 25 cm;

- the presence of a non-combustible wall 12.5 cm thick;

- from the ceiling with thermal insulation - 80 cm, without insulation protection - 1.2 m;

- from the firebox door to the wall - 1.25 m;

- from the load-bearing wall to the front wall of the modification with a remote firebox - 3 cm.

The installation of a sauna stove in a niche is prohibited.

The nuances of preparing the foundation

The equipment of the floor for the stove depends on the material of the bath and the weight of the product. The concrete surface does not need to be reinforced, but for comfortable cleaning, you can trim the stove zone with fireclay bricks, tiles or porcelain stoneware.

If the room has a wooden floor type, you need:

- make a special podium - a separate foundation, taking into account the weight of the metal product, protective screen, filled tank and chimney;

- bring the pedestal 15-20 cm beyond the line of the metal furnace;

- select the depth of the base according to the depth of the main foundation;

- do not tie the structure to the load-bearing foundation so that the structure has a normal shrinkage.

When preparing the base, a concrete solution is used from 1 part of cement, water, 3 parts of sand. Initially, a pit is dug, then formwork is placed, a reinforcing mesh is laid and concrete dough is poured. After hardening, the structure is covered with double waterproofing, and then the brick is laid in two rows. As a result, the foundation will be 20 cm smaller than the finished floor.

Preparatory work for the walls

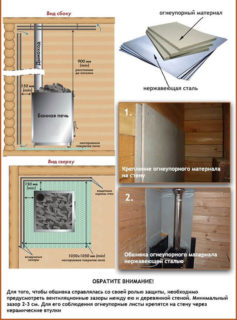

Installation of the stove in a sauna made of non-combustible materials or installation at 50 cm from the flammable surface does not require wall preparation. A portal is needed for a stove with a remote type of firebox. You can protect walls from the effects of fire and hot metal as follows:

- applying plaster on a metal mesh with a layer of 2.5 cm;

- installation of a special stainless steel screen with further installation of non-glue materials;

- porcelain stoneware or stone cladding on a non-combustible surface per 1 cm layer;

- additional processing - the frame is covered with a fire-retardant agent, finished with volcanic stone, soapstone.

It is allowed to use ready-made protective screens in the bath room. Reflective sheathing is positioned with 2-3 cm ventilation gaps. The sheets of refractory material are fixed with ceramic bushings. Fire-resistant gypsum board is mounted on a profile or glue, superisol - on glue or disc dowels.

A protective brick frame can be erected from 2-3 sides of the stove. It will prevent the impact of a hot stove on the combustible wall, accumulate heat and maintain the temperature in the steam room. The laying scheme is implemented step by step:

- The choice of material is red, clinker, bassoon or fireclay bricks with a half-brick arrangement.

- Preparation of mortar - cement or fireclay clay.

- Compliance with the distance to the wall surface of 5-15 cm.

- Compliance with the building height - 20 cm more than the heating unit.

- Organization of vents (holes) or combustion flaps for normal circulation of air masses.

The optimum thickness of the brick screen is 120 mm.

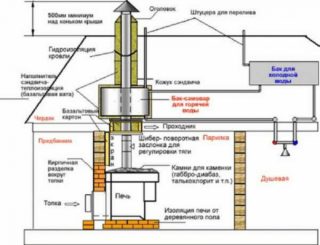

Assembling the heating device

The step-by-step algorithm for assembling the furnace is usually indicated by the manufacturer's instructions. For example, Vesuvius models with a remote firebox are difficult to install, but easier to operate. In general, the assembly of units is carried out according to the general principle:

- Installation of the stove taking into account the distance to the ceiling (120 cm) and walls (32 cm). For modifications with asbestos-steel protection, it is allowed to reduce the distance to 26 cm.

- Installation of a hinged tank on the air duct nozzle. The volume of the tank is selected according to the number of family members at the rate of 10 liters per person.

- Installation of heat exchange equipment. The heat exchanger is positioned so that the bottom of the tank is above the upper connection.

- Organization of the pipeline. The pipes are fixed at an angle of 30 degrees. To eliminate the risk of water freezing, a drain valve is installed.

- Fastening of a straight chimney 5 m long (from the mouth to the grate). The chimney should rise 50 cm above the roof covering or ridge and 150 cm away from the parapet.

A spark arrestor can be installed to protect the roof from fire.

First fire

The stove is heated on the street with a preliminary inspection of the body, grate, door, heat exchanger for damage and ease of opening. The firebox is performed as follows:

- Installing the unit on a level surface.

- Connecting a temporary heating system to a heat exchanger and filling it with water.

- Fastening a temporary chimney to a height of 2 m.

- Putting ½ the volume of firewood in the firebox, lighting the fire.

- Combustion support for 1 hour.

- Periodic lining of firewood.

During the heating process, the quality of the stones is checked at the same time. An unpleasant smell indicates the presence of sulfur compounds in the material. It is not recommended to use it in a steam room and a bath.

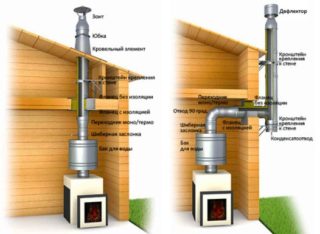

Chimney installation

A Finnish sauna or bathhouse can be equipped with ceramic, brick, single-walled metal or sandwich channels for fume extraction.For self-arrangement, a sandwich pipe in the form of two tubes of acid-resistant steel with internal thermal insulation is suitable.

Observe the instructions for assembly work:

- Mark the hole for the stainless steel cutting pipe and dismantle the overlap along the line.

- Apply fire-resistant impregnation to the log house.

- Fix the cutting tube with self-tapping screws and fill the gap with a heat insulator to a layer of more than 7.5 mm. A blockage of 13 cm should remain from the pipe to the beam, 38 cm from the chimney to the wall.

- Attach a single-wall pipe to the furnace nozzle, apply welding or mastic along the seam, put a gate.

- Attach the adapter to the sandwich chimney.

- Install the rest of the parts on the brackets so that the joints do not fall into the groove.

The deflector is placed after the roof cut.

The process of self-installation of a wood-burning stove in a bath

A wood-fired type of metal stove is the best option for self-installation. The work is done as follows:

- Primary firing on the street for removal of production coating and testing for integrity.

- Preparing the hole for the pipe. When it is withdrawn through the ceiling, a non-combustible protective ring is applied to the site.

- Installation of thermal insulation materials and protective screens on the walls. If a stove in a sauna or bath is equipped with a heating chamber from the steam room or dressing room, you will need a protective portal.

- The metal unit is mounted in a prepared place.

- Execution of a brick casing.

- Installation of a chimney and other elements.

- Test furnace - the quality of heating and the level of smoke production are checked.

The heating in the room is carried out on condition that the tank is filled with water and there are stones in the stove.

Installation of a stove structure on a wooden floor

If the iron unit weighs up to 700 kg and needs to be installed on strong logs, the foundation is not equipped. The organization of a heat-resistant podium is allowed:

- a sheet of metal is placed on a sheet of basalt cardboard;

- brick, natural or artificial stone is laid on the floor;

- the pedestal is decorated with ceramic or porcelain stoneware tiles.

To prevent ignition from sparks or coals, the area in front of the firebox is finished with a metal sheet with sides of 40 cm.

A massive sauna stove is placed on the foundation:

- For plastic soils with high GWL - screw. A pile is screwed in at the corners of the furnace to the depth of the main foundation, to which channels and heads are attached. A sheet of metal is welded on top, concrete dough is poured onto it;

- For hard soils - shallow. The monolithic base is poured 30-40 cm.

A shallow foundation does not need reinforcement.

Installation of modifications with a remote firebox

The factory heater is installed according to the manufacturer's instructions. If it is planned to install a powerful sauna stove after the construction of the building, the distance from the product with a remote firebox to the wall is observed. Models in a heat-resistant housing can be removed by 25 cm, without it by 40 cm.

The wall surface is covered with thermal insulation, then with a steel sheet. A gap of 50 cm is required between the unit and the wooden wall. The area next to the furnace is lined with refractory materials.

The fuel niche is lined with bricks with a thermal gap for metal expansion of 2-2.5 cm. An asbestos cord should be placed in the gap. Brickwork is allowed around the building.

Installation rules for electric furnaces

In private construction, to equip saunas and baths, electric cookers powered from a 220 V network are used.When installing them, the following rules should be observed:

- Select the type and cross-section of the cable according to the power of the stove. For modifications for 3; 4.5 and 6 kW, a 1.5 mm2 conductor is suitable.

- Lay the floor under the electric heater with ceramic tiles.

- Leave a gap of at least 7 cm from the stove fence to shelves and flammable objects.

- Place the washed stones only on top of the heating element.

- If you have a stove, use lamps designed for a temperature limit of up to 140 degrees.

- Place the ventilation opening behind the heater at a height of 5-10 cm from the floor.

- Serve the water as carefully as possible, do not pour the stones with sea water.

Do not use abrasive products to care for the sauna heater.

Extinguishing media and personal safety

The bath room may be equipped with automatic or manual fire extinguishing systems. In saunas, drencher or sprinkler sprinklers are justified. Smoke detectors or devices can be installed in the dressing room or dressing room.

For the purpose of personal safety, it is necessary:

- Do not cover the stove with various objects.

- Control the steam temperature and air circulation;

- Do not be in the bath with high blood pressure or drinking alcohol.

- Use special aromatic oils intended for baths.

- Do not put clothes on the oven to dry.

The air temperature in the steam room is set individually.

Self-installation of a metal stove in a sauna or bath room is possible subject to certain rules. The serviceability of the equipment and human safety depend on the preparation of the installation site, walls and chimney.