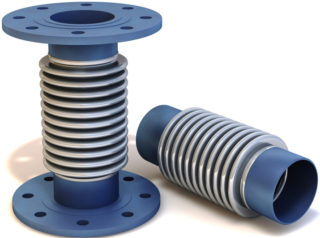

Expansion compensation devices prevent the destruction of circuits when heating mains. The bellows expansion joint for steel pipes balances the misalignment in the system due to improper installation, reduces the loads from the operation of the units and the movement of flows. The bellows is a corrugated springy capsule of a single or multi-layer structure made of metals, non-metals or composite materials.

The principle of operation of the bellows expansion joint

Stresses arise in the pipeline, the heating compensator counteracts deformation due to the elastic shell. The contours fail due to the load of axial shear and rotation, depending on this, certain types of relief inserts are used.

Devices must be installed on systems:

- heating lines under pressure;

- closed supply and return circuits;

- pipelines for pumping gases and liquids.

Bellows units reliably connect sections of the heating main if they are correctly selected and installed. Structures dampen vibration with small and large amplitudes, while the amplitude of oscillations should not exceed 10% of the total shifts of the compensator.

Universal or balanced inserts are used if typical devices do not meet the requirements or there is a risk of a pressure surge in the network that exceeds the permissible values.

Specifications

Bellows are produced using rolled steel with a thickness of 0.3 - 0.5 mm. The outlet batch is tested for resistance to corrosion from chlorine at a temperature of + 150 ° C. The tightness is tested by hydrostatic compression using bubbles of nitrogen, air or helium. Expansion, test substance leaks and pressure drop are not allowed in expansion joints.

The devices are tested for resistance to heating by increasing the temperature to + 270 ° C and holding under these conditions for at least 1 hour. Internal tears, swelling and delamination are checked. The stiffness test is carried out by compressing and stretching the sample, the value must correspond to GOST 286.1997.

The longitudinal seams of the shells during manufacture are performed by welding at the same distance from each other. Metal bellows are produced by molding with corrugation calibration. Small diameter devices are made by hydraulic pressing.

Basic dimensions

Visual and instrumental examination is used to determine the appearance. The presence of corrosion coating on the pipes and bellows, marking is visually established. There should be no damage, dents, or drops of frozen metal on the body. The compensator for polypropylene heating pipes should not have bundles of different sizes at the ends of the pipe.

Using the measurement, the parameters are checked:

- flow section size;

- working length of the device;

- wall thickness and inner diameter of welding flanges;

- perpendicularity of the branch pipe axis to the cut end.

The diameters and lengths of bellows inserts are determined depending on the installation site, operating parameters of the heating main and the power of the heating equipment.Engineering workers carry out a technical calculation and select the dimensions of the device in accordance with the standard.

Varieties of expansion joints

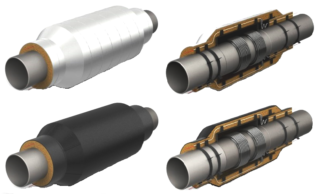

The constructive solution of the compensator determines the purpose of the product and its displacement during operation. Devices without thermal and waterproofing are produced, or preliminary protection is provided on the body, depending on the type of heating main (air or underground).

The manufacturer manufactures types of expansion joints:

- axial;

- flanged;

- angular;

- cardan;

- shear;

- starting.

Unloaded expansion joints are used in heating mains to prevent thrust loads, seismic types are used in areas of suspected earthquakes. External pressure devices are installed in the lines when there is a high pressure of liquid or gas in the environment or a lack of it is felt.

The structures differ in length and diameter, the number of bellows and the type of steel, the size and grade of metal of the branch pipes. Products work in rotation, stretching, bending, compression, and are available with or without connecting flanges.

Axial

KSO expansion joints for pipelines reduce the axial displacement of the pipeline, reduce vibration and prevent destruction from expansion when heated. The efficiency depends on the number of bellows and rings. The difference from other types lies in the threaded connection with the line branch pipes.

Axial expansion joints differ in characteristics:

- through passage size 15 - 100 mm;

- withstands a pressure of 16 bar;

- lengthwise size - 260 mm;

- permits movement along the axis for compression up to 30 mm, for expansion - 20 mm;

- axial stiffness parameter - 30 - 89 kg / mm.

The movement limiter and the branch pipe are made of galvanized metal, the bellows and the inner screen are made of stainless steel. For the protective case, steel is used, the device is produced in one-section and is designed for the temperature of the energy carrier up to + 90 ° C.

Flanged

The bellows of this type is made of rubber or rubber, for the flanges the raw material is heat-resistant metal, and the cord is made of durable fabric. Flange mounting greatly simplifies the installation of products. Compensators are used in a chemically active environment, they are used in heat supply and air conditioning, they are installed during the reconstruction and repair of boiler equipment.

Flanged structures reduce vibration, reduce temperature shifts along the length, and compensate for the deviation from the central axis of the pipeline.

Main settings:

- nominal diameter - 32 - 800 mm;

- withstand the temperature of the energy carrier -10 - + 135 ° С;

- work with a pressure of 16 bar.

Flanges are loose and solid in structure; they are attached to pipe elements with pins, bolts using washers and nuts. Paronite gaskets are used, sometimes steel ones, made of thermally expanding granite or fluoroplastic, are used.

Angular

The KSP (rotary) is placed in the case of limited space, when it is possible to compensate only for the shift along the axis and rotation of the contour without changing the plane. Contains a bellows, a guide element and fasteners. The device provides for the shift of the pipe along the selected angle, for this there are hinged or gimbal stops.

Characteristics of rotary (angle) expansion joints:

- nominal through diameter - 15 - 1600 mm;

- maximum head - 1.6 - 4 MPa;

- movement along the axis - 24 - 200 mm;

- shield and protective box made of steel;

- bellows material - stainless steel;

- available with one or two sections;

- works with an energy carrier heated to +85 - + 150 ° С.

Corner structures are used as part of a heating main and for pumping oil, gas, and are used in the chemical industry.

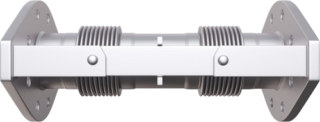

Gimbal

Bellows expansion joints of pipelines balance the movement of the contour in different planes, thanks to the hinge elements, they are bent in the direction of the central axis. The displacement of the line is compensated for along the X, Y, Z axes and in terms of rotation due to shrinkage, vibration. Flexible design allows for deformation in rigid contours.

Specifications:

- designed, calculated and manufactured in accordance with the EJMA standard;

- contain in the structure 2 bellows with cardan-type hinges;

- sideways displaced by a multiple of 100 mm (100, 200, 300, 400), other displacement sizes must be ordered separately;

- nominal through diameter - 25 - 1000 mm;

- works with energy carrier temperatures -190 - + 850 ° С.

The bellows is made of stainless steel, connectors, chrome-plated steel pipes. It is placed in the design position by welding or using a swivel flange. Used in any piping system.

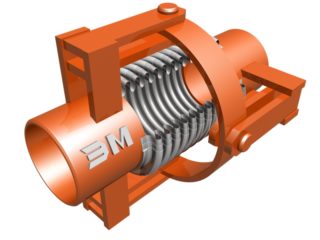

Shear

KSSO compensators balance the shift due to longitudinal compression or lengthening of the contour under the influence of temperature, eliminate the consequences of misalignment. The design includes a corrugated capsule, a guide piece and fasteners. Longitudinal displacement is coordinated by means of guide pins.

Parameters of shear compensating devices:

- nominal diameter of the passage - 32 - 500 mm;

- maximum head 0.6 - 4 MPa;

- bellows, ties and branch pipe are made of stainless steel;

- the material of the protective screen is chosen by the customer;

- withstands the temperature of the energy carrier up to + 850 ° С.

Sliding devices are made in one and two sections, they are used to compensate for the stress in pipelines of oil, water, steam, gas. They are used in various industrial sectors and in energy complexes.

Starting

The SCK compensator is used temporarily as a disposable device when starting the heating main or hot water pipeline.

Technical specifications:

- nominal diameter DN nominal - 50 - 100 mm;

- shift along the central axis - 80 - 175 mm;

- device rigidity at the level of 430 - 2300 N / mm;

- transports water with temperatures up to + 150 ° С, steam - 250 ° С;

- allows the speed of water flow up to 5 m / s, steam - 65 m / s;

- the normalized pressure when starting the line should not exceed 1.5 MPa.

The starting expansion joint is used when laying the contour using the channelless method. The material of the body, pipes and bellows is selected by the customer.

Installing the bellows expansion joint

The reference points for the expansion joints are the location of the supports, when the line is divided into sections and the position is predetermined. The supporting elements are calibrated with a level in three axes to ensure the correct operation of the heating main. Pipes on supports should slide without additional friction; for this, clamps with fluoroplastic gaskets are used.

Suggested installation points:

- behind the thermal support;

- behind supports from bends and deflections;

- between sliding supports.

The course of movement of the energy carrier is taken into account when installing expansion joints with protective inner sleeves. Guiding elements prevent the pipes from sliding along a tangent straight line. It takes into account the diameter DN in millimeters, the working pressure and the ability to balance shifts. The diameter should correspond to the same parameter of the heating main.

Distance between pipes

The main line is divided into sections if one bellows structure is not enough to balance shifts or there are branches on the heating main. The length of the segment should not be more than one expansion joint can cover. The device on site is selected in accordance with the operating conditions and specifications. A description of the compensator model is given in the working documentation for the installation of the heating system.

Usually, the bellows device cuts at a distance of two nominal diameters from the retaining part. If it is placed between the supports, the distance to the supporting elements is 4 DN. Such dimensions prevent bending of the pipeline and keep it to a minimum.

If several polypropylene circuits are installed in parallel, it is taken into account that the diameter of the expansion joint is slightly larger than the diameter of the pipe. In this case, the bellows structures are staggered, and the distance between the pipes does not increase and is done according to the standards of the technical passport of the heating main.

Correct operation

Compensating inserts are thermally insulated with polyurethane foam, if the line is protected from heat loss. Compulsory isolation from leaks is performed.

Waterproofing materials:

- polyethylene - in a closed installation in underground conditions;

- galvanized - for thermal communications, arranged in an open way.

The insulation is set taking into account the possible displacement of the casing during expansion or contraction of the pipeline. The thermal protection is checked and repaired from time to time along with the insulation of the mains.

Safety standards

The service life of the expansion joints is provided for 30 years, while the devices can be stored in the warehouse for no more than 5 years before starting work.

Within the service life, the following loads are allowed:

- compression-stretching from minimum to maximum - 10 cycles;

- reduction or elongation by 70% of the maximum and minimum limit - 150 cycles;

- shifts within 20% of the working stroke - 10 thousand cycles.

Bellows expansion joints must have manufacturer's certificates confirming compliance with the regulations. For welding, certified materials are used, the installation is carried out by certified workers. It is forbidden to use structures in conditions exceeding the permissible ones. Expansion joints cannot be used as props when installing heating mains.