Housing standards do not allow residents of high-rise buildings to unauthorizedly connect to the heating main. A permit is required to make underfloor heating from central heating in the apartment. Waterproofing will prevent leaks, and removing multiple radiators will keep the system under pressure.

- Restrictions when connecting underfloor heating from central heating

- Connection diagrams

- Radiator connection

- Connection via a heating radiator with a regulator

- Heat exchanger connection

- Serial connection

- Horizontal wiring

- Choice of pipes

- XLPE

- Polypropylene compound

- Copper

- Metal-plastic

- The nuances of connecting a warm floor from central heating

- Warm floor or radiator

Restrictions when connecting underfloor heating from central heating

The underfloor heating belongs to systems with high temperatures, so the heat carrier, according to the standards, cannot be heated more than + 55 ° C. In practice, pipes get +35 - 45 ° С.

The temperature of the water and floor is different, it is recommended to heat the surface:

- in living rooms - up to + 26 ° С;

- in the premises of the kitchen, corridor, bathroom, balcony, loggia - up to + 31 ° С.

The difference in heating value between the supply and return side should not exceed 10 ° C.

Connection diagrams

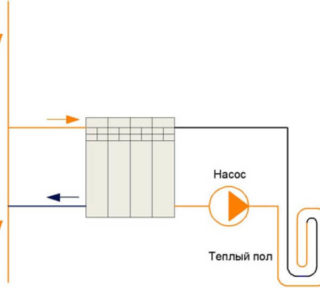

The principle of underfloor heating is based on the principle of connecting a low temperature circuit. The correct scheme ensures that the coolant flows through the riser, which is located separately from the radiator pipeline. It can be a heat exchanger at a general heating point, a unit in a high-rise building or in a consumer's dwelling. The scheme is negotiated with the heat supplier and the management office. In practice, the floor is connected according to one of the schemes, permission is issued in half of the cases.

Radiator connection

The system is made in the form of two pipelines. After the tie-in, a shut-off valve is placed in the main riser, on each battery there are 2 valves on the return and supply lines. The material of the circuits is 25 mm polypropylene, and the heat exchangers are connected with a 20 mm pipe.

If there is a return flow on the upper line from the bottom, and the supply to the battery from the top, the floor heating works efficiently. On the lower branch, return and supply are supplied from the bottom, so only 85% of the energy is used.

Connection via a heating radiator with a regulator

Thermal heads of the RTL type control the temperature of the heating medium with a direct connection of a water heating floor.

An automatic valve cuts into the return and coordinates the set temperature:

- water has not reached the set value - uninterrupted circulation is allowed;

- the temperature rises to normal - the head drive closes the valve, the fluid supply stops;

- cooling down leads to the opening of the passage and the movement of water.

The connection through the radiator to the regulator helps to reduce the surface heating to a comfortable perceived value. Installation of a thermal head and a three-way valve is required.

Heat exchanger connection

In such a scheme, the negative impact of a warm water floor in an apartment with central heating is eliminated.

The heat exchanger is selected in accordance with the capacity of the batteries, installed in place of the radiator and performs the following functions:

- maintains the hydraulic section of the line;

- allows you to independently regulate the heating of two circuits.

The underfloor heating pipe does not have a direct outlet to the common system; in case of an emergency, it is not required to disconnect the common riser from the boiler. Reduces the risk of flooding downstairs neighbors in an apartment building.

Serial connection

To supply a warm floor from heating through a one-pipe system, you need to include a pump and a mixing unit in the connection diagram.

During installation, the following conditions are met:

- the inner diameter of the supply pipes is not less than 25 mm, while the largest number of batteries on the ring should not exceed 5;

- the loop of the water floor is connected to the return line after all radiators;

- a three-way mixing valve is cut in to maintain the required temperature.

This connection is used by the owners of old-style apartments for unauthorized insertion into a vertical single-pipe riser.

Horizontal wiring

A design pipe layout is used, which ensures a rhythmic distribution of heat over the area. This takes into account the distance from the vertical barriers and the furniture arrangement plan. Such planning of horizontal wiring allows you to efficiently use the energy of the coolant in the pipes.

The collector-beam pipe arrangement system is popular. The collectors are installed so that the size of the laid areas between the heating floor zones and the distributors is the smallest. This helps to balance the line and coordinate the temperature in different rooms.

Choice of pipes

The materials used have similar properties and are used for underfloor heating systems. Copper pipes are durable, but they are expensive, which limits their use. Polymeric materials are affordable and provide the desired performance during operation.

XLPE

Differs in acid resistance, high wear resistance and flexibility.

The following types are produced:

- pePEX - with an internal anti-diffusion coating, used for underfloor heating;

- PEX - for cold and hot supply;

- evalPEX - for radiator heating.

The disadvantages are manifested in the impossibility of welding, therefore, the entire section changes in an accident. External insulation is used to limit heat loss.

Polypropylene compound

The advantages are good sound insulation and low friction, which leads to the maintenance of the flow rate.

Views:

- PN10 - cold water;

- PN20 - hot;

- PN25 - heating (with internal reinforcement).

Polypropylene pipes do not conduct heat well, therefore they do not require a protective layer, are impermeable to acids and have a low price. The disadvantages include a short service life - about 30 years.

Copper

High quality copper or zinc-copper alloys (zinc 5%) are used. The pipes are coated on the outside with a layer of polyethylene or polyvinyl chloride to reduce heat loss. For heating systems, products are used with the EN 1057 marking, indicating a phosphoric treatment to increase resistance to moisture.

Copper does not corrode, has durability, therefore it is used for up to 100 years. The pipes can withstand temperatures from -100 ° C to + 250 ° C without cracking and deformation.

Metal-plastic

The material has a low elongation index, which is close to metal. Flexibility allows collectors to be stacked in hard-to-reach places. High-quality metal-plastic has a high price and is not welded.

Thermal conductivity with a coefficient of 0.45 expands the scope of pipes, the material works effectively in a warm water floor system.

The nuances of connecting a warm floor from central heating

The quality of the wiring and installation of the elements will affect the life of the water floor, heating efficiency, safety. Professional plumbers from the service office provide a warranty period to identify problems.

Warm floor or radiator

The underfloor heating system keeps your feet warm. Comfort matters when choosing how to heat a room.

Radiators dry the air in the apartment and contribute to a deterioration in well-being; underfloor heating does not have such an effect on the atmosphere.

In the harsh Russian climate, only a warm floor will not be enough - the home will not completely warm up. Experts advise installing at the same time a warm water floor system and leaving batteries in the room for efficient heating of the area.