To build an electric heated floor under the tiles with your own hands, you need to familiarize yourself with some of the details of its arrangement. These include both the choice of the method of electrical heating, as well as the preparation of a solid foundation. In addition, the user will need to understand the methods for calculating the power of electric floors of the selected type.

Possible options

Electric floors are classified into the following types:

- heating cable systems;

- warm floors based on IR films;

- heating mats.

The first and third varieties are best suited for a tiled finish. Heating mats and heating cables are similar in design, differing only in design details. When meeting with them, pay attention to the following nuances:

- The underfloor heating cable goes on sale in the form of coils of a given length, differing in thermal efficiency.

- Electric mats are made by laying the cores of the same cable on a pre-formed base. It is wound with a certain pitch and has a heat transfer corresponding to the number of turns.

- Infrared systems are equipped with IR films, along the edges of which there are electrical contacts for connecting power.

To determine the number of cables, mats or IR plates required for arranging the floor, you will need to calculate the total power sufficient to heat the house.

Calculation of the power of underfloor heating

You can start installing an electric underfloor heating under the tiles after determining the power required to heat one room and all rooms. To find this indicator, it is most convenient to proceed from empirically obtained data. To heat 1 square meter of area, an electric cable heater with a capacity of about 140-180 watts is required. Based on this indicator, you should choose the desired length of the heating cable, having familiarized yourself with its passport data.

When choosing a heating film coating, one should proceed from the fact that the required power in this case is on average 150-220 W / sq. meter.

When choosing any option, it is also important to determine the electrical power that will be consumed by the elements of the underfloor heating from the home electrical network.

Preparatory stage

Before making electric underfloor heating under the tiles with your own hands, you will need to prepare a reliable base. It can have the following versions:

- wooden (parquet) floor;

- concrete pouring;

- reinforced concrete floor slabs.

Preparatory measures are reduced to their alignment and placement of structural elements, on which cables, mats or IR films are subsequently mounted. If necessary, you will have to insulate the base. You should also worry about the purchase of all the necessary equipment and prepare the tool, without which the installation of the heating system is impossible.

Tools and materials

When arranging a warm floor, the following electrical installation tool will be required:

- side cutters for cutting wires and stripping insulation, screwdriver and pliers;

- a soldering iron used for tinning bare ends, as well as solder and flux;

- to cut through the grooves in the floor and wall, you need a grinder with a stone disc or a perforator;

- for continuity of electrical circuits, you should stock up on a measuring device - a multimeter.

In addition to the electrical operations, construction work is ahead, during which devices will be required to prepare and level the screed. In addition to a drill with a nozzle, a typical kit includes a spacious container and a full set of leveling tools:

- ordinary and notched spatulas;

- the rule of the required length;

- rollers and brushes for applying and leveling the primer;

- devices for marking and controlling surfaces: tape measure, building level, ruler and markers.

From the materials, you will need to purchase elements of the underfloor heating of the selected type in appropriate quantities, as well as hardware and components for leveling the base (preparing the screed).

Pouring screed and laying tiles

To increase heat transfer, the heating cable under the tiles is often installed directly into the cement grout. When arranging it, the following options are possible:

- wet screed, made on the basis of a cement composition with the addition of various plasticizers and fiberglass;

- semi-dry mixture obtained by limiting the amount of water in its mass;

- dry screed, prepared on the basis of ready-made mixtures containing small expanded clay granules or slag fragments.

The thickness of the electric underfloor heating installed in the screed is usually set in the range from 3 to 5 cm. It is not recommended to violate these indicators for reasons of safe operation of the heating structure. Laying tiles on a ready-made electric floor is allowed only after the previously poured screed is completely dry - after four weeks.

Floors without screed

The design of heating mats and heating cables does not exclude the possibility of laying them without a screed. In the assortment of electric type underfloor heating offered on the market, there are samples with flat and very thin cables. It is laid directly on the concrete base, and then fixed with the hardware supplied with the kit. The step-by-step procedure for arranging an electric floor allows ceramic tiles to be laid on top of a securely fixed cable or flat mats. Sometimes moisture-resistant multi-layer plywood is used as a substrate for it.

Electrical connection

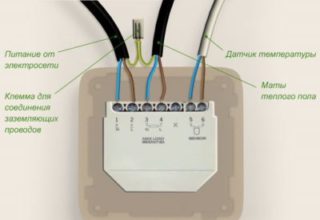

To connect the electrical elements laid in the heated floor installed under the tiles, you will need to allocate a separate power line. It must be protected with a circuit breaker, for reliability to include an individual RCD in series with it. Before starting electrical work, you should decide on the connection area for the warm floor. To do this, you need to select in a convenient place on the wall a site for installing a thermostat, to which the power supply line of the heating system is connected.

In rooms with high humidity, the thermostatic control unit is moved to another room or corridor, where there is free access to it.

A control unit with a thermal sensor is purchased separately, only in rare cases this device is included in the delivery set. In this case, as a rule, there are no difficulties, since all blocks have standard dimensions and are easily mounted on a standard socket. The advantages of this option include the ability to choose any sample you like from the assortment offered by the market. It can be a simple electromechanical model or a modern electronic control module with an option for programming operating modes.