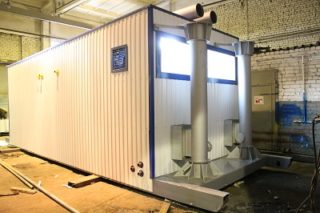

Modern block-modular boiler rooms are designed to heat residential and industrial buildings with gas. BMK are a spatial system not divided by internal partitions. The modules are assembled at the factory and delivered to the site.

- The device of block-modular systems

- Pros and cons of block boiler houses

- The main types of boiler rooms

- Stationary BMK

- Mobile systems

- Fuel classification

- Gas devices

- Liquid fuel systems

- Solid fuel models

- Electrical installations

- Features of production

- Rosenergoprom

- Kotlostroyservice

- Buildkomplekt

- EnergoLider

- AllianceHeat

- Requirements for block-modular boiler rooms

The device of block-modular systems

Boiler equipment is designed to obtain hot water and supply it to heat supply and water supply systems. Manufacturers produce systems in accordance with GOST 15150, the design of which includes:

- block module (one or more) in the factory assembly;

- a metal pipe that provides a chimney.

Boiler rooms are manufactured using technologies:

- closed double-circuit system - a barrier heat exchanger separates the boiler and network circuits to prevent temperature surges, overpressure;

- multi-boiler control systems - air parameters, temperatures are monitored automatically. The fuel combustion mode is adjusted in the same way;

- frequency control systems - variable frequency drives are installed on pumps, smoke exhausters and fans, which save energy;

- vacuum deaerators and vapor coolers - reduce heat loss.

Natural and liquefied gas, diesel fuel can be used as fuel.

Pros and cons of block boiler houses

A block-modular boiler house has several advantages over a stationary one:

- savings on the construction of a capital building for a boiler;

- reducing the cost of using the heating route;

- reduction of heat loss during the transportation of the coolant;

- high category of readiness for commissioning;

- quick installation - equipment is connected in 3-10 days, the system is deployed in 4 hours;

- automation of the management process - reducing the risks of failures and accidents;

- the ability to select a system in terms of power - there are models from 0.2 to 50 MW.

The disadvantages of devices include:

- implementation of commissioning procedures exclusively by specialists;

- risks of emergency situations during fires and unauthorized operation;

- use of explosive fuels.

Block boiler houses are operated according to the design period for 15-20 years.

The main types of boiler rooms

Depending on the design, there are two types of devices.

Stationary BMK

The boiler room is completely assembled at the factory and is designed to provide hot water supply after heating the carrier. Has the following characteristics:

- performance - a heat generator with any power is connected to it;

- admissibility of cascade connection - the technology provides for the integration of several boilers into a common network;

- versatility of the used fuel and connection - compatible with gas tanks and central lines;

- ease of conversion for a different type of coolant.

Stationary devices are delivered to the site and unloaded by a truck crane.The ready-made installation with automation, control unit, circulation equipment, wiring and security systems is mounted on the foundation.

Mobile systems

A transportable modular boiler room is installed in rooms with a maximum area of up to 5 thousand square meters. The capacity of the structure is no more than 500 kW, so it cannot be supplemented with auxiliary systems. Low-power plants are easy to install without preparatory measures.

Mobile BMKs are 30% more expensive than stationary ones.

Fuel classification

To effectively heat a private house or a country cottage, it is worth not only choosing the type of installation. You need to think about the type of fuel used. According to this criterion, block-boiler houses are divided into several groups.

Gas devices

Natural fuel or butane ensures the economical operation of boiler houses. The minus of the installations is the expensive installation, but the low cost of gas pays for the costs already in the first season of operation. The modular gas boiler room is connected to the boiler, which solves the problem of providing the house with hot water.

The gas boiler is safe, equipped with atmospheric burners with a minimum noise level, adapted to low pressure. The equipment is suitable for residential buildings and industrial workshops.

Liquid fuel systems

Block boiler houses run on diesel or kerosene. They will be a good solution for areas without gas mains. The diesel type of modules is distinguished by a low cost of fuel resources, autonomy of operation and high efficiency.

Devices powered by diesel or kerosene are easily converted to gas.

Solid fuel models

A plant fired with coal, briquettes or wood is a backup option. The solid type of fuel is notable for its low cost, and the boiler house itself does not depend on the electric or gas line.

The systems automatically remove smoke and have an efficiency of more than 85%. The disadvantage of solid fuel BMK is the need for storage space for coal, firewood or pellets.

Electrical installations

The construction of the boiler house does not take a long time due to the low cost and ease of connecting the equipment. The structures do not harm the environment, are safe, and have an efficiency of more than 90%. The electric type of block boiler houses has one drawback - the cost of operation is 10 times more expensive than when using gas.

Modern brands also produce biofuel boiler houses, which are more expensive than all these types.

Features of production

Kotlostroyservice - certified modular boiler house 2.5 MW

A block diesel, solid fuel or gas boiler house is not produced at the factory fully assembled. The manufacturer only complements the main unit with heat generators and auxiliary equipment. In the basic configuration, the systems are one or more boilers, water treatment lines, sediments and electromechanical units.

Installations from several manufacturers are in demand on the territory of the Russian Federation.

Rosenergoprom

There are representations in Novosibirsk, Kemerovo region, Yekaterinburg. They produce solid fuel, gas, fuel oil and diesel boilers. Furnaces of devices - manual or mechanical type. They are engaged in the design and installation of systems.

Kotlostroyservice

There are representative offices in many cities, including Moscow, Izhevsk, Voronezh, Novy Urengoy. The production of block modular boiler houses operating on diesel and gas has been established since 1998. The line of free-standing, attached equipment, single and twin boilers is represented by models with a capacity of 100 kW - 5 MW.

Buildkomplekt

Production is concentrated in Yekaterinburg. The enterprise produces mobile and stationary boilers for any type of fuel, provides services for design, installation supervision and commissioning of BMK.

EnergoLider

A manufacturer with a representative office in 4 cities of the Russian Federation, which produces hot water and steam boilers. Carries out a set of works on their design, commissioning, training of service personnel.

AllianceHeat

Brand from the city of Stary Oskol, performing the construction of turnkey systems with a capacity of 1-60 MW. Provides design services for boiler houses with further commissioning. The units operate on natural gas diesel fuel, fuel oil, and are connected to 220 and 380 V.

Enterprises are obliged to provide buyers with documents on compliance with GOST, SNiP and PPB, as well as certificates of conformity from Rostekhnadzor.

Requirements for block-modular boiler rooms

When buying and connecting a boiler room, the following nuances must be taken into account:

- Installation is carried out only after calculations, project approval and visual inspection of the module for damage.

- Smoke exhaust systems must comply with clause 5.12.2 of SNiP for boiler equipment.

- To ensure the safe operation of equipment, a sanitary protection zone is organized on the basis of SP 89.13330 and 42.13330.

- Modular stationary modifications are installed only on the foundation.

- If a dangerous type of fuel is used, before connecting the boiler, grounding is organized, a fire alarm and leak detectors are installed.

- The pipelines of the system are equipped with instrumentation and are connected in a flange-bolted manner.

- The design approval in the assembly is carried out within 72 hours.

The connection and maintenance of the BMK apartment building, administrative institution, production lines must be qualified personnel who have undergone training.

Compared to traditional heating systems, block-modular boiler houses are economical. A private farm, a production workshop or the owners of a residential building save up to 50% of heating bills. In addition to economic feasibility, the units are distinguished by minimal fuel consumption and thermal efficiency.