Rockwool is a Danish company founded in 1909. It is a world renowned manufacturer of construction products, materials and insulation. One of the main activities is the production of mineral (stone, basalt) wool. It has over 30 branches in Europe, America and Asia, including the Russian Federation. One of the types of insulation Rockwool has the Fasad Butts trademark, it is used to insulate the outer walls of new and reconstructed buildings, including historical monuments. Russian factories of this brand are located in the Moscow, Leningrad and Chelyabinsk regions.

Insulation features

The Rockwool Facade Butts mineral wool produced by the company is made from fibers several microns thick, obtained by centrifuging a molten mass consisting of basalt volcanic gravel and sand.

The transformation of fibers into Rockwool insulation boards differs from other methods:

- irregular entangled fiber structure when forming the product;

- additional impregnation with non-flammable compounds that improve fiber adhesion;

- optimal pressing;

- sintering effect at a temperature not exceeding 1000 ° С.

In addition to thermal insulation, Rockwool panels are distinguished by excellent sound insulation qualities. In terms of protection efficiency, an insulating material with a standard thickness of 80-100 mm can replace a brickwork thickness of one to one and a half red clay bricks. The minimum water absorption of the panels allows the application of a protective wet cement-sand or lime plaster - simple or with decorative properties. For reliability, it is better to use a fiberglass or metal reinforcing mesh with cells of 1-2 millimeters.

The insulation is sold in polyethylene bags with a characteristic pattern and detailed instructions for use. A pack can, depending on the subspecies and thickness of the panels, contain from 1 to 8 units. The maximum weight of a bundle with 8 sheets does not exceed 15.5 kilograms.

Slabs Rockwool Facade Butts can be used when installing a ventilated facade, when between the finishing - various sheet or thin-slab, ceramic, stone or artificial, polymer products - through longitudinal channels are left for free movement of outside atmospheric air.

Types of heaters Rockwool Facade

Materials can be classified into several subspecies, used for specific purposes and for solving specific problems of insulating the facades of various buildings.

Butts

The standard, most commonly used type of insulation. It differs in its size and the number of panels in the package:

- 1000x600x25, 8 pieces per pack; can be used in the restoration of facades for thermal protection of curved finishing details;

- 1000x600x80, 1 piece per package;

- 1200x500x100, 2 pieces per pack;

Butts-D

Plates of double density, marked with the letter "D": 1000x600x100, 3 pieces per package;

Butts-Optima

Panels used in Rockwool Wet Facade Complexes with a RockFasade thin plaster layer:

- 1200x500x150, 2 pieces per pack;

- 1200х500х200, 1 piece per package

Strips of thermal insulation Butts-lamella, not cut into slabs and panels, are distinguished by increased flexibility and transverse arrangement of fibers, perpendicular to the facade.Used for restoration, protection of round and broken parts of facades: 1200x150 / 200x50 / 200

Specifications

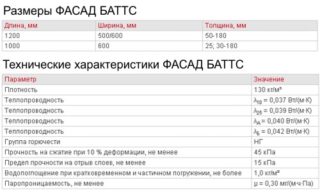

All panels and their subspecies of Rockwool Facade Butts thermal insulation, with the exception of density, have similar physical and technical characteristics:

- Thermal conductivity - 0.037 W / MK.

- Flammability group - NG;

- Compressive strength - 40-45 kPa.

- Adhesive (tear-off) strength - 15 kPa.

- Water absorption from volume - no more than 1%.

- Water vapor permeability - 2 mg / MhPA.

Density of material

In accordance with the fact that the area of use of Rockwool facade heat-shielding plates is quite extensive, for different types and subspecies the density is taken:

- Butts - 130 kg / m³;

- Butts-D - double, for the outer layer - 180, for the inner layer - 95 kg / m³;

- Butts-Optima - 110 kg / m³.

Insulation device and installation

Installation of insulation Rockwool Facade Butts is carried out on the outer surfaces of the walls using special adhesives. To simplify the initial fixation, in addition to glue mastic, special dowels with wide heads are often used, which practically do not crush the material due to its high density.

In the case of using Rockwool for a ventilated facade, first a frame or a subsystem fixed to the outer surface of the wall is made of horizontal and vertical wooden or metal battens. Their dimensions must match in modulus with the dimensions of the Rockwool slabs, as well as the sheet topcoat.

The panels are inserted into the cells with an effort and are fixed with dowels, self-tapping screws, tapes, wire. Sealing of joints is ensured by polyurethane foam or silicone mastic.

Advantages and disadvantages

The positive qualities of thermal insulation material include:

- actual dual purpose - thermal and noise protection;

- high vapor permeability, which allows steam generated inside the premises to escape from temperature extremes and human activity;

- increased modulus of elasticity, which does not allow the slabs to receive damage from deformations of the walls, protected facades;

- incombustibility and high fire safety;

- ease of installation, allowing for hand-made execution;

- service life declared by the manufacturer - at least 50 years;

- resistance to biological pollution and damage by harmful microorganisms and insects;

- absence of emission of harmful vapors and dust, unfavorable for human breathing.

This type of insulation has practically no drawbacks. These include the relatively high cost. But reliable operation over a long period of time makes this disadvantage insignificant.

Rockwool Facade Butts are used for insulation and noise protection of multi-apartment panel and brick houses during their construction or overhaul, for private individual construction - from country houses to suburban or intracity mansions and cottages. Thermal insulation Rockwool can be successfully used for warming attics and installing additional living quarters on them such as attics or mezzanines.