The level of comfort of living in an apartment and a private house largely depends on the efficiency of its heating. On the construction market, there are many modern systems designed for the main and additional heating of premises. Cable underfloor heating is an excellent option for arranging living and auxiliary rooms. In this case, the installation can be done by hand, without involving hired craftsmen.

Cable floor types

The basis of heating devices is a wire that generates heat when an electric current is passed through it. At the same time, the options for the operation of the elements have significant differences.

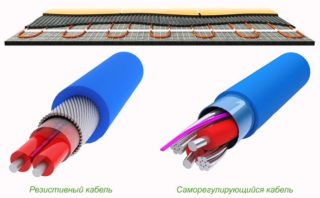

The following types of heating cable are on sale:

- Resistive single-core. Consists of one wire, which is laid in a closed circuit. The core serves both as a heater and a conductor. Differs in reliability, ease of installation and temperature unevenness throughout. The product emits high electromagnetic radiation, not suitable for installation in bedrooms and children's rooms.

- Resistive two-wire. It is a line with two cores. One wire creates heat, and the second is short (wired). The system is easy to install and generates virtually no electromagnetic radiation. It can be placed in rooms where people stay for a long time. However, the price of the product is quite high.

- Self-adjusting. This is the most complex but effective design. The heating material is a matrix that maintains the same temperature along the entire length of the line. The conductor resistance is automatically regulated, which eliminates the possibility of overheating.

Heating products are manufactured in the form of continuous wires and mats. The first type is laid with a snake on a previously prepared base. The mats are made in the form of a polymer mesh with a wire embedded in it. Coating is carried out by area in accordance with the configuration of the room and the arrangement of furniture.

Construction device

The basis of the cable floor is a metal core, which is made of high resistance metal. The thicker the wire, the more reliable, durable and more accurate it is in regulation. However, thin cables bend better and are easier to shape.

On top of the metal there is a layer of insulation made of polymer material resistant to high temperatures. The insulation is flexible, elastic, due to which the probability of its destruction when laying the cable is completely excluded.

The next layer is a dense copper braid. It serves to protect the internal insulation from external damage and neutralize electromagnetic radiation.

Another layer of insulation is applied over the screen. It protects the structure from moisture penetration into it, which can cause metal corrosion. The polymer coating is characterized by increased strength and sufficient elasticity.

Depending on the capacity, the cable lines have a thickness of 4 to 10 mm. Thinner wires are used in mats. Their cross-section varies within 2-5 mm, but there is no risk of damage during installation, since the mats are already sold with cores rigidly fixed on the base.

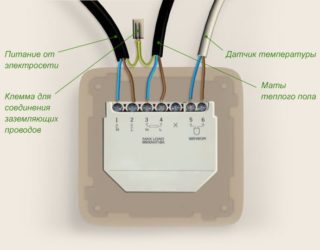

To increase the efficiency and safety of cable products, the equipment for regulation and control is included with the product.

- Thermostat. The device is designed to set and maintain a certain temperature in the room. On sale are mechanical and electronic devices, including those with remote control.

- Thermal sensors. These are devices that measure the room temperature and send a signal to the controller. Depending on the coating used, the parts are installed outside and inside, or only on the outside of the flooring.

It is recommended to purchase cable heaters and control devices at certified retail outlets so as not to run into a fake. If the wire burns out, it will not be possible to repair it, based on the installation features.

Advantages and disadvantages

Cable heaters compare favorably with film and water counterparts.

The main advantages are as follows:

- Efficiency. Ensuring effective heat distribution throughout the room.

- Comfort of living. Walking on a warm surface is much more pleasant than walking on a cold one. Reduces the risk of colds.

- Versatility. Installation of a cable floor can be carried out in any type of premises - bathroom, kitchen, balcony, corridor, nursery.

- Power. With the right approach, the floor from the heating cable can be used as the main source of heat.

- Environmental Safety. No harmful substances are released during operation.

- Reliability. The wires are strong enough to withstand tie pressure and bending.

- Durability. Quality products are designed to last at least 25 years.

Disadvantages include:

- raising the floor above the level of the floor slab;

- a tangible price that not everyone can afford;

- large electricity bills.

The listed criteria will help to determine which warm floor is better, film infrared or cable.

Power calculation

When calculating the amount of material, the amount of power per unit area should be taken as the basis. For main heating with a cable system, the required value is 100 W / m². With auxiliary heating, the value can vary between 20-50 W / m². Proceeding from this, you should select a product, focusing on the heat release of products per unit of length.

Manufacturers produce cables with indicators of 15-25 W / r.m. This data will help you calculate the need for a wire. It should be borne in mind that the distance between the turns should not be less than 30 cm so that the heat distribution over the floor is even. Do not get carried away with high-power conductors, since most thermostats are designed for 2-2.5 kW.

Laying rules

Each heating device is accompanied by an instruction, which describes the rules for installation, operation and recommended safety measures.

The heating cable can be laid in the following ways:

- On a layer of heat insulator under a concrete screed up to 150 mm thick. This option is called accumulating. The generated energy is absorbed by the thickness of the stone, which stores it for several hours. This solution allows you to run the heater periodically and save money on bills.

- In a screed array (direct action). The cable is located at a distance of 2-3 cm from the outer surface of the screed, which allows the maximum heat transfer to the finish coating.

- Under the finish. This technology involves the use of heating mats. The products are pre-fixed on the base, then ceramic tiles are laid on them without additional pouring. A good and effective solution is the arrangement of a self-leveling polymer floor.

To ensure full heating of the room, it is necessary to cover at least 70% of its area with a cable system. When laying, sharp bends and intersections of wires are not allowed. It is inappropriate to place them under cabinet furniture and household appliances.

Combination of cable underfloor heating with coatings

Heating efficiency with cable heaters will be achieved if a material with high thermal conductivity is laid on top of them. Otherwise, it will act as an insulator, absorbing the generated energy.

The best solutions for covering a cable floor are the following:

- Tile or porcelain stoneware. Together with glue, this material perfectly conducts heat with minimal losses. It can be used in rooms with high humidity and in living rooms, provided that you choose products with a color, relief and texture that matches the interior.

- Laminate. The panels pressed from several layers conduct heat somewhat worse, but well enough for the matte system to perform its functions efficiently with an average amount of energy consumed.

- Linoleum. The polymer heats up well from the mats, practically not absorbing heat. You need to purchase rolls without a backing, made from natural materials.

When choosing a topcoat, you need to make a choice in favor of durable materials, since replacing them after installing the furniture will be a very problematic event.

Maintenance and repair

It is not recommended to set the maximum cable temperature during operation. This leads to its rapid wear and tear. For prevention purposes, it is necessary to periodically change control and monitoring devices. It is advisable to do this before the expiration of the warranty period.

Only the thermostat and sensors are subject to repair. After pouring with concrete, cables and mats become non-removable, it is impossible to get them out of the screed or from under the tiles without damage.