The disadvantage of centralized heating mains is the slow heating of radiators. The process of pumping a comfortable temperature can be accelerated by using a water heater. A water heater for heating is connected to the system, collects heat flows and distributes them around the room. Before installing the equipment, you need to understand the features of its operation, types and installation procedure.

- Application specificity and design

- Classification of heaters according to the shape of the tubes

- Smooth pipe

- Lamellar

- Bimetallic

- Varieties according to the method of installation

- Conditions and features of operation

- Pros and cons of a water heater for heating

- Installation tips

- Specificity of using water heaters for heating

Application specificity and design

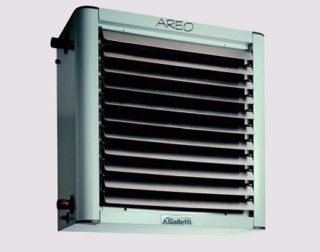

The fan heater is suitable for rooms from 150 m2, but it can also be used in everyday life to enhance the capabilities of radiators. The device is also mounted in large spaces without batteries. The optimal location of the water heater is supply ventilation, because the inlet flow will be heated.

It is possible to heat the supply stream for the purpose of heating and preserving heat. Water models also prevent condensation in the air ducts. Currently, heating heaters are popular, which consist of the following elements:

- Heating unit. The main part of the structure is a steel tube with aluminum fins. The outer diameter of the nozzle is 37 mm, without ribs - 16 mm, the distance between the ribs is 2.8 mm. The protruding parts give off heat, retain it even with an intensive blowing mode.

- Tubes. Arranged in 2, 3 or 4 rows in a flat rectangular frame. Air masses are supplied by an axial or radial fan.

- Jalousie. Carried out to the front, they provide the direction of the flows working for heating.

- Electric motor. Ensures the operation of the fan. With a heating power of 115 kW, the electric motor can have a power of 0.5 to 1 kW.

- Housing with mounting holes. Made of anti-corrosion steel or plastic.

Air heaters are designed for a maximum coolant temperature of 200 degrees and a maximum pressure of 1.2 kPa.

Classification of heaters according to the shape of the tubes

The devices are equipped with tubes directed across the air movement. To eliminate the risks of airborne airing, water is directed through the nozzles from the bottom up. The connecting flanges at the ends of the body have holes located for connections with ventilation ducts. Depending on the shape of the tubes, there are several modifications of the air heaters.

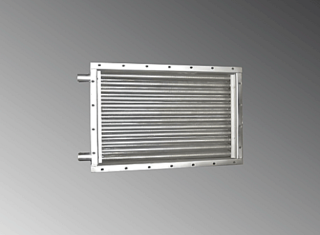

Smooth pipe

The heaters are made of hollow pipes 20-32 mm in diameter, located at a distance of 0.5 cm from each other. The heater can be selected according to the location of the tubes in the water heater:

- Corridor. The ends of the elements are welded into the upper and lower manifolds. The water is directed through the inlet to the distribution box. It moves through the pipes and heats them, being discharged in the form of condensate or chilled liquid.

- Chess. Differs in high resistance to air currents. The heater works normally when the air dust content is less than 0.5 mg / m2 and the inlet water temperature is +20 degrees.

Smooth pipe devices are suitable for low air consumption.

Lamellar

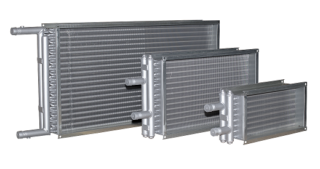

Modifications with ribbing to increase heat transfer. Plates are rectangular and round.The elements are equipped with tubes on which a corrugated sheet of steel 1 cm wide and 0.4 mm thick is wound.

The medium-sized model is a 3-row version, and the large one comes with 4 rows of pipes. Dimensions of plates of medium variation with a thickness of 0.5 mm - 11.7x13.6 cm. Large plates differ from them only in length - 17.5 mm. The large plates are arranged in a zigzag manner, and the middle ones are arranged in the form of a corridor.

The type of heating plate heaters can be identified by the marking. Models СДТ4009В are compatible with steam and are installed vertically. Air heater STD3010G can be connected horizontally to a system with water.

Bimetallic

A device with spiral-rolled type fins, suitable for water heating medium with a maximum temperature of 180 degrees. Bimetallic air heaters of the KSK3 and KPZ series are medium in size and are equipped with 3 rows of tubes. Large devices such as KSK4 and KP4 have 4 rows of nozzles.

The similarity of the KSK of both types lies in the design. They consist of heat exchangers, side shields, tube grids and baffled covers. Heat exchangers are made in the form of 2 tubes. The inner 1.6 cm in diameter is made of steel with aluminum outer fins. The transverse distance between the nozzles is 4.15 cm, the longitudinal distance is 3.6 cm.

Varieties according to the method of installation

Depending on the design of the case, you can choose a fan heater:

- Outdoor type. Installed without fasteners, quickly connected to the water supply. Mobile models are easy to carry to a new location.

- Wall type. The wall heater is equipped with a mounting bracket for adjusting the vertical position. The element is fastened with anchor bolts, after which the water circuit is connected.

Household appliances are single-circuit, connected only to hot or cold water supply.

Conditions and features of operation

The principle of operation of a water heater for heating equipped with a fan is based on the heat exchange of two working media. Hot water is used as the primary heat carrier, and air is used as the secondary one. Heating of air masses is performed by transferring heat from hot water to a cold air flow. The efficiency of heat transfer depends on the temperature difference - it must be large.

When operating devices, several requirements must be observed:

- Performance figures are calculated prior to installation in a large room.

- Household models are compact, compatible with steam or water heating.

- The use of water with a temperature of more than 180 degrees in the mains is unacceptable - the heater will fail.

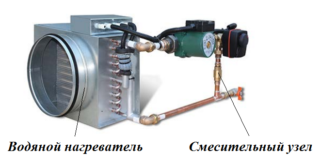

- For large rooms, a power control system for the heater is used in the form of a mixer with a three- or two-way valve.

- The maximum density of aggressive impurities in the air during the operation of the device is specified in GN 2.2.5.686-98 and GOST 12.1.007-76.

- The energy efficiency of the heater depends on the heat transfer coefficient. The value is indicated in the passport.

- Before installation in a home workshop or garage, it is required to install filters to remove chemical impurities.

- Three-row models are suitable for ventilation systems that supply outside air at temperatures from 0 to -40 degrees.

- Four-row modifications are launched in winter only when the temperature increases to 30 degrees per hour.

- The units are not suitable for forced or artificial ventilation - they pump air through duct elements.

The lowest temperature at which the air heater will work is -25 degrees.

Pros and cons of a water heater for heating

The advantages of water-type air heaters include:

- easy installation in comparison with communications where there is a radiator;

- heating efficiency and speed;

- performance - the heater can heat a country house or production area;

- operational safety;

- automatic shutdown and activation of heating for models with temperature sensors;

- smooth adjustment and setting of operating modes;

- compatibility with the central system or local networks - boilers;

- noiselessness of work;

- no load on the electrical line.

Heating equipment has several disadvantages:

- dependent on the presence of water in the mains;

- the coolant must be supplied to the installation area of the devices;

- complexity of maintenance;

- stopping heat supply if the fan stops.

Despite several drawbacks, water heaters are distinguished by heating efficiency and economy of water consumption.

Installation tips

The water air heater is installed in rooms connected to the central heating main. When self-installation, it is worth following the recommendations of specialists:

- The diagonal of the heater depends on the peculiarities of the channel bends, the type of damper and structural elements.

- To protect the heater from freezing, the installation is carried out in rooms with a temperature of at least 0 degrees.

- Before starting the installation, it is necessary to inspect the plates and tubes for integrity.

- Welding flanges are most easily butt welded.

- Direct-flow valves of air outlets are located at the top of the outlet and supply manifolds.

- The joints of the device and the ventilation system are sealed.

- Wall-mounted models are installed by attaching the console with two self-tapping screws.

In the absence of experience in connecting and strapping the work system, it is better to entrust the specialists.

Specificity of using water heaters for heating

Fan heaters of water type are used for heating premises with a large area - shops or offices. They allow you to quickly dry carpets or car seats, so they can be used in car washes and dry cleaners.

Water heat sources are justified for basements with high humidity levels. They can be installed in garages, construction cars, workshops, on the territory of warehouses or workshops for the production of polymers.

Duct water air heaters are suitable for maintaining a comfortable temperature in the home and at work. Energy-saving equipment practically does not consume electricity and gas, which allows you to save on utility bills.