Batteries are actively used as elements of a heating system, but not all varieties are suitable for installation in residential premises. For the choice, the device of the radiator, material and shape matter. The type is determined taking into account the state of the heating main, communications, the type of energy carrier in the pipes and the time of the last repair of the system. The influence of water hammer is taken into account, so a combination of factors makes it difficult to choose a radiator for an apartment or house.

Features of the radiator design

The battery is a separate heating device, which contains elements with internal channels for the movement of the energy carrier. Heat is removed by convection, radiation and heat transfer.

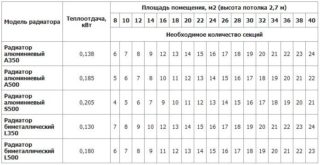

Sectional views allow you to increase the heating area by adding elements. Panel installations cannot be changed in shape, which is taken into account when calculating and installing the system. The accompanying passport indicates the temperature criteria for the operation of the device, the parameters of the working pressure, and heat transfer.

Sectional radiator

The sectional heating battery device consists of a metal pipeline in the form of aligned horizontal collectors through which water flows. The channels are connected using vertical tubes of small diameter, and the entire system is housed in a cast iron, steel or aluminum housing. Separate sections are twisted on the thread.

Radiators are used to heat the room, so the device design affects the quality of heat exchange. The material of the heat exchanger and the body plays a role, therefore, bimetallic options are used, including 2 types of materials.

Radiators should be able to be cleaned periodically as Scale settling on the inner surface reduces heat transfer.

Types of radiators by design

The heating capacity of batteries depends on the exchange area, therefore the design is important.

The choice of form is influenced by factors:

- the height of the ceilings and the area of the room;

- maximum pressure in the heating main;

- duration of operation (long-term or periodic);

- boiler power, pipe material, characteristics of other devices in the system;

- chemical composition and physical properties of the energy carrier.

Radiators are selected in the form of sections, panels, plate and tubular types. The climate in the region and the required heating conditions, the presence of aggressive factors, the cost of batteries affect.

Sectional radiators

In heat exchangers, sections of the same type are connected, which inside have 2 - 4 channels for the movement of water. Prefabricated elements are made of aluminum, steel, cast iron of various shapes and lengths. Heating of the room is coordinated by the number and size of the sections.

Prefabricated batteries transfer heat by convection and radiation, work economically, they are equipped with manual and automatic temperature regulators, taps, valves. The products are inexpensive, the choice of the center distance makes them popular for different buildings.

The disadvantages include the danger of leaks with a sharp jump in pressure, difficulties with cleaning the internal channels and external cleaning of the intersection space.

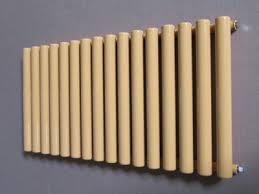

Tubular batteries

The sectional design of the radiator includes 1 - 6 vertical collectors, which are combined by the upper and lower pipes, the coolant circulates freely. Heat transfer depends on the diameter of the pipes and the dimensions of the heat exchanger (0.3 - 3.0 m). Installations withstand pressure up to 20 atm.

Tubular batteries withstand pressure drops and water shocks. Smooth interior contours resist the build-up of dirt and deposits. Welded joints do not leak. The exterior fits into a variety of interiors. Radiators are available in all sizes, differ in the shape of the case. The disadvantage is the high cost.

Panel models

The panel radiator looks like two metal shields welded together. Inside the plates there are vertical channels for the circulation of the energy carrier, and on the outside ribs are attached, which increase the heat transfer surface. The panels are arranged in 2 or 3 rows, the material is steel.

The advantages of the models:

- low inertia makes it possible to quickly respond to changes in external temperature;

- due to its lightness, massive mounts are not required;

- compact devices are located in any part of the room;

- low price.

To heat the model, half the water is needed than for a sectional battery. The disadvantage is that panel installations do not withstand high pressure in the line; a purified energy carrier must be poured into the system without dirt and impurities. Poor painting of joints leads to corrosion and leaks.

Lamellar

The operating principle of the radiator is convectional exchange. The heat exchanger is a core with fixed thin metal fins. The inner tubes are used to transfer water. This type of radiators is installed in industrial and public buildings, multi-apartment buildings with a centralized highway.

The degree of heating is regulated by increasing the number of plates. Radiators effectively heat the room, but when the boiler is turned off, cooling occurs quickly. The coolant must be heated to a high temperature and flow through under pressure.

Classification by material of manufacture

Radiators must serve for a long time and withstand various aggressive influences. In a multi-storey building, the operating conditions are not entirely suitable, since the coolant does not differ in quality. Aluminum appliances are not installed in the apartment. the radiator is worn out and will quickly fail.

Manufacturers take care of damage to the insides and protect the surface with polymers, but such options are expensive and not always in demand. Bimetallic and steel installations are less damaged by corrosion. Cast iron batteries are suitable for centralized heating from a city branch.

Cast iron

The heavy radiator is divided into sections and features powerful heat transfer. The device tolerates energy pollution, but limescale and scale accumulate on the insides. The units operate for a long time, sometimes they are removed, disassembled and cleaned under pressure in order to restore the original heat transfer.

Simultaneously with cleaning, the intersection gaskets change, which eventually fail. Cast iron batteries have an outdated design and are not installed in closed automatic heating systems. In apartments that are heated from the central branch, such batteries withstand pressure changes and water hammer.

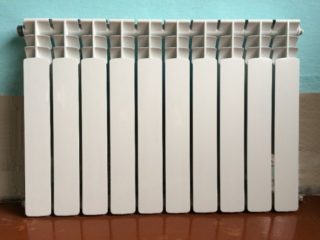

Aluminum

The aluminum radiator in the heating system gives off energy efficiently and has a large area due to the impressive number of fins. Devices are produced that can withstand a pressure in the system of about 12 atm., And the pressure during pressure testing is at a level of 18 atm.

Cutaway options for an aluminum radiator:

- one-piece structures with cast sections;

- extruded type with mechanically connected elements;

- combined options.

The advantages of aluminum radiators include small dimensions, lightness, and large area. The disadvantage is the destruction of metal in an aqueous medium, especially in the presence of stray currents in the line. The oxide film inside is disturbed by an aggressive energy carrier, gas is released during the reaction, which, in a closed circuit, leads to a rupture of the battery.

Bimetal

Bimetallic plants are of high quality. The purpose and design of the radiator allows the device to operate under high pressure conditions and with the danger of water hammer.

Batteries are produced sectional or cast, there are two types:

- made of aluminum and steel;

- made of aluminum and copper.

In bimetallic devices, contact between water and aluminum is not provided. This design improves thermal conductivity, reduces weight and increases strength. Radiators made of two metals withstand pressure up to 100 atm., Corrosion is not observed.

Design and principle of operation

The principle of operation of the radiator is that the heated energy carrier moves through the pipe system and enters the batteries, transfers heat, then moves along the return line to the heating source. The radiator heats the air in the room by means of radiation and convection. The ratio of heat radiation to convection is different for different types of devices.

Steel and cast iron radiators heat the room with radiation, and plate and panel heaters transfer energy by convection due to the large total area of fins and strips. The warm stream tends upward, instead of being pulled in cold air, which heats up.

Diy radiator connection

In the multi-apartment sector, batteries are mounted on one side of the room. The radiator is connected in several ways, depending on the pipe layout.

Diagonal or cross connection is used. The underwater pipe is connected from one side of the battery in the upper section, and the outlet pipe is led out from the other side at the bottom. Such a scheme is relevant for installations with a large number of sections of considerable length.

The bottom connection provides for connecting the inlet and outlet of the radiator from the bottom to two nozzles on both sides of the heat exchanger. The scheme is characterized by low efficiency, but this option cannot be avoided if the heat supply system is arranged in the floor.