Log structures remain in demand, although many new building materials have appeared. Wood retains heat well, regulates the level of humidity in the room well. However, sometimes in winter, residents of such houses observe the freezing of individual walls. Therefore, you should figure out how to insulate a log house from a log.

Requirements for the properties of insulation materials

When choosing insulation for a log house, it is imperative to take into account the characteristics of the wood. A suitable material must have the following properties:

- the same vapor permeability as wood;

- moisture resistance, which will protect the tree from moisture accumulation, decay;

- fire safety;

- immunity to the occurrence of fungus, pests;

- it is good to let air in, create natural ventilation;

- have a structure that allows the insulation to fit snugly against wooden walls.

Insulating a house from a log outside or inside will significantly reduce heat loss and heating costs. Living in the house will become much more comfortable.

For the purpose of insulating a wooden house, you cannot use:

- Styrofoam;

- expanded polystyrene;

- foam for installation;

- sealants.

The use of vapor-proof materials will cause the wood to rot. If you protect it from the inside with a film, a wooden house will turn into a thermos, the meaning of building such a house will be lost.

Recommended materials for insulating a log house

Only natural insulation should be used for wood: sawdust, seaweed, straw and others. For external insulation of an old wooden house, it is allowed to use ecowool and mineral wool. The latter are inexpensive, easy to install, and are similar in technological properties to natural materials for thermal insulation.

Sawdust

In terms of heat preservation, they are no different from modern thermal insulation.

Advantages:

- low price;

- environmental friendliness.

Disadvantages:

- quickly ignite;

- rot in case of moisture ingress;

- pests often settle in them.

Such material is not used in its pure form. Usually, a log house is insulated from the outside with granules or pressed plates. The first ones fall asleep from the bottom and to the top. Since such a material gives some shrinkage, over time, bedding will be required. Pressed boards are securely attached to the battens.

Ecowool

Insulation is made from cellulose fibers (80%) and antiseptic (20%). The latter protects it from mold and rodents. The material is suitable for insulation of any premises.

With proper use, ecowool easily takes the required shape, adheres well to logs. For this reason, it retains heat for a long time.

Advantages:

- reliability;

- combustion resistance;

- inaccessible to rodents;

- prevents the appearance of mold, fungi;

- low thermal conductivity;

- environmental friendliness.

Disadvantages:

- applied using special equipment;

- shrinks;

- under the influence of high temperatures begins to smolder.

Ecowool is applied to a pre-installed lathing by spraying.In this case, the surface must be moistened with water. After spraying, a layer is formed, which will subsequently protect the structure from freezing.

Straw

Straw has a thermal conductivity 4 times less than that of wood, and 8 times less than that of bricks.

Advantages:

- the ability to absorb moisture, if necessary, release it into the air (while harmful impurities are removed from the latter);

- provides oxygen circulation in the room, ventilation even with closed windows and doors;

- low price;

- ecological cleanliness;

- excellent sound insulation properties (due to the porous structure).

Disadvantages:

- duration of work during use;

- large labor costs.

Despite the fragility of the insulation, it contains 3 times more silica than wood. As a building material, straw is stronger and more durable than wood.

Seaweed

Kamka thermal insulation material is made from algae emissions after a storm. It has become widespread due to its availability.

Advantages:

- excellent thermal insulation properties;

- good noise isolator;

- rodents and insects do not start in the material due to the high content of calcium salts;

- does not rot;

- does not support combustion.

The main disadvantage: it breaks easily as a result of mechanical stress.

Kamka is able to absorb moisture in case of its excess in the room and give it away if the air is too dry.

Due to the high content of nutrients (including iodine), kamka creates a suitable microclimate for people suffering from disorders of the central nervous system and respiratory organs.

Mineral wool

It is made from rock alloys (silicate), but has a synthetic base. Mineral wool is produced in the form of mats, slabs, which provides easy attachment to the surfaces of the log house.

Advantages:

- significant resistance to decay;

- good thermal insulation characteristics;

- fire safety.

Disadvantages:

- deformed over time;

- emits harmful substances under the influence of high temperature;

- susceptible to mold.

Mineral wool can be based on various substances: glass melt, blast-furnace slags, basalt rock.

The process of internal insulation of a wooden structure

Before insulating a log house from the outside with your own hands, you should consider the option of thermal insulation of the structure from the inside. It is quite possible that these measures will be enough, and you will not have to spoil the outer walls.

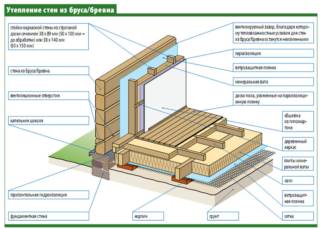

Ceiling

Since the heat mostly comes out through the ceiling, it is worth starting with it to warm the house. For this purpose, you need to prepare:

- knife;

- a hammer;

- tile adhesive;

- hacksaw;

- screwdriver.

Materials:

- insulation;

- nails, screws;

- edged boards;

- foam for installation;

- drywall.

The process consists of the following stages:

- Prepare a frame from boards. It should be borne in mind that it will affect the future height of the ceiling. Edged boards are fixed at a distance of no more than a meter.

- For waterproofing purposes, carefully fill the space between the installed boards with glassine.

- Lay in mineral wool. It is allowed to use glue if necessary.

- Sheathe with drywall, screwing it to the frame.

In the end, it remains to do the finishing and cladding.

Walls

To work, you need to purchase the following tools, materials:

- roulette;

- screwdriver;

- plumb line;

- level;

- chisel;

- drill (percussion);

- a hammer;

- dowels, screws;

- screwdriver;

- foam for mounting, felt;

- wooden beams;

- insulation (ecowool, mineral wool), drywall, putty.

Wall insulation technology:

- Fill up the cracks with foam, felt.

- Build the crate with wooden beams. They are attached to the wall with screws, dowels every 30 cm. The approximate distance between adjacent beams is 1 m. On top of the vertical beams, attach the same horizontal ones.

- To prevent the appearance of fungus, treat wooden elements with an antiseptic.

- Place the insulation tightly between the fixed beams without the use of glue.

- Make a vapor barrier using plastic wrap (lay on insulation).

At the end of the work, finishing should be done: sheathe the walls with plasterboard (screw to the crate), carefully putty all the cracks.

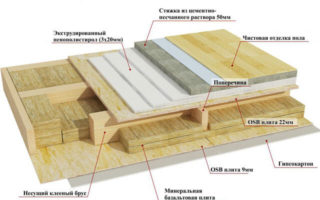

Floor

To complete the work you will need:

- a hammer;

- drill;

- electric jigsaw;

- hacksaw;

- knife, pencil, nails;

- plane;

- roulette, level;

- insulation.

The main stages of floor insulation work:

- Level the surface, eliminate defects.

- Lay a waterproofing material to protect the insulation from moisture.

- Lay out the logs at a distance of no more than 50 cm.The suitable size of the log is 5 × 10 cm, the thickness is at least 5 cm.

- Put mineral wool between the latter.

- Place the PVC membrane on top.

The floor will be completely finished after installing waterproof plywood or chipboard flooring.

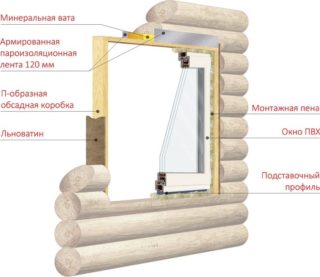

Windows and doors

It is very easy to close gaps and holes in frames.

Tools and materials:

- aluminum ruler;

- polyurethane foam.

Using an aluminum ruler, you need to check the tightness of doors and windows, pushing it into accessible places near the frames. Blow out the cracks found with foam. It is recommended to use soft polyurethane foam.