Insulation of the ceiling of a cold attic is an event that contributes to the creation of a comfortable microclimate on the upper floor of a private house. The need to insulate the floor slab is justified by the law of physics, according to which warm air rises up. After contact with the cold ceiling, it goes down and cools the entire room. To prevent this from happening, an insulating barrier should be made between the ceiling and the attic. When choosing a material for insulating a cold attic on floor slabs, it is necessary to pay attention to such qualities as environmental and fire safety, biological and chemical inertness, low thermal conductivity and hygroscopicity, long service life. The requirements for thermal insulation are established by SNIP, and the laying rules are established by GOST. The standards are quite strict, but they are justified by safety criteria.

Insulation of the attic floor with mineral wool

Mineral wool has a long history of use and is very popular in private construction. The technology for the production of mineral wool is constantly being improved, due to which more and more high-quality products are at the disposal of consumers. Basalt wool TechnoNIKOL is in the greatest demand, which has better characteristics than slag and glass counterparts.

Material advantages:

- low thermal conductivity;

- practically unlimited service life;

- ecological cleanliness;

- high degree of sound insulation;

- ease of installation;

- incombustibility;

- flexibility and resilience;

- static form and volume.

Insulation of the attic floor on wooden beams with mineral wool should be carried out in closed clothing, eye and respiratory protection. The material releases the smallest fibers into the air, which cause acute irritation when it comes into contact with the body.

Since the boards are soft, they are laid in a frame that serves as a support for the final or intermediate floor. Since the substance is good for air permeability, moisture from the lower rooms can accumulate in it. To remove it, a vapor-permeable membrane is used.

Installation technology is as follows:

- A vapor-permeable film is laid on a wooden ceiling. It is better to fix it with a household stapler. The edges of the fabric must be brought out to the walls at a level of 30 cm and also fixed.

- Making a frame from boards. The mesh size of the lattice is matched to the format of the material. Beforehand, the wood must be well dried, treated with an antiseptic and fire retardant.

- Cutting the roll into pieces of the desired length. Placement of insulation in the frame. If gaps remain, they are sealed with polyurethane foam.

- Nailing vapor-permeable fabric to the crate. The joints are sealed with tape.

- Installation of finishing or intermediate flooring.

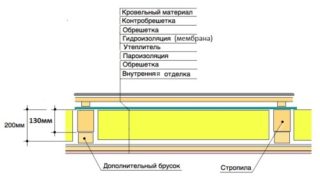

Insulation of the attic roof is carried out in the same way. Plates are installed in a spacer between the rafters of the walls and roof. In order for the insulation to sit tightly in the niches, you need to make meshes 2-3 cm larger than the plates. This will avoid the appearance of gaps.

It is necessary to remove the material from the packaging immediately before use so that it does not become saturated with moisture.

Foam insulation

Polyfoam is a plate consisting of many porous balls. Manufacturers produce products 100 × 100 cm in size, 50 mm and 100 mm thick.Since the material does not allow air to pass through, it is used to equip reinforced concrete structures, concrete basements and other structures equipped with forced ventilation.

Advantages of expanded polystyrene:

- low density;

- ease;

- waterproofness;

- resistance to mold and mildew;

- ease of cutting and installation;

- durability;

- environmental Safety;

- affordable cost;

- no need to use vapor-permeable fabrics and additional insulation.

The technology of laying insulation on the attic reinforced concrete floor:

- Cleaning the slab from protruding fragments, sealing cracks and holes. If necessary, leveling with a solution is carried out.

- Surface treatment with a primer. Application of a layer of liquid waterproofing.

- If the floor of the attic will be subjected to regular vertical loads, a diagram is drawn up and a lathing is made with a mesh of 100 × 100 cm, a height of 5 cm or 10 cm.

- Penoplex plates are laid directly on the floor or in the frame. When placed on concrete, glue is used and the slabs are staggered. During the installation process, the slots must be blown out with foam.

- The floor covering is attached. The choice can be made in favor of boards, OSB boards or laminated panels.

To avoid squeaks, you need to lay a substrate on the insulation, and only then lay the topcoat.

Using sawdust as insulation

To carry out the arrangement of the attic of a bathhouse and a private house, sawdust is rarely used, since you can find more efficient and durable factory-made materials. But with a limited construction budget, a decision is made to insulate the structure with sawdust.

This substance has the following advantages:

- woodworking waste is worthless;

- ecological purity of natural raw materials;

- vapor permeability;

- low specific gravity;

- ease of installation.

The disadvantages include high hygroscopicity and a tendency to decay when high humidity is formed.

Insulation of the attic on the floor slabs is carried out in this way:

- Sawdust is well dried, treated with an antiseptic and a hydrophobic agent. Then the raw material is well dried again.

- The surface of the attic floor is lined with a vapor barrier fabric. Its edges from all sides rise to the Mauerlat by 20-30 cm.

- Clay, gypsum or alabaster mortar is mixed in a concrete mixer.

- Sawdust is poured into the container and mixed with the base for 3-4 minutes, after which the mixture is poured onto the ceiling. The mortar is carefully leveled using a level and a wide spatula.

- After complete drying, the insulated floor becomes covered with cracks. They are covered with a mixture of clay and sand. After that, the surface is sanded, dust and debris are removed from it.

- The vapor-permeable canvas is being laid. The edges of the second layer are connected to the edges of the fabric laid in the first stage of the arrangement. It is advisable to choose a dense film that will function as a substrate.

In the attic, you can lay any finish that is resistant to humidity and temperature extremes. Here you need to make the right choice so as not to redo the work at the end of winter.

Warming with expanded clay

This insulation for floors is made from a clay-based mixture by vulcanization. The process results in rounded granules. To improve the sorbing properties and compaction of the mixture, they are crushed.

Material advantages:

- affordable cost;

- low thermal conductivity;

- ease of use;

- light weight;

- ecological cleanliness;

- incombustibility.

The disadvantages include shrinkage of the layer under its own weight and high hygroscopicity. If you choose expanded clay, this insulation of the floor will have to be replaced every 3-4 years.

Instructions for thermal insulation of the attic with expanded clay:

- Laying a double vapor barrier film on the base.The joints between the strips are glued with tape.

- Manufacturing of a frame from boards with parameters corresponding to the finish coating. Before installation, the wood must be impregnated with an antiseptic and drying oil.

- Mixing granules of fine, medium and coarse fraction. Pouring the mixture into the cells. Carrying out material leveling. Another option for filling is the manufacture of a solution of gypsum densely saturated with expanded clay. In this case, the crate can not be made, but the solution can be poured directly onto the film.

- Installation of the second windbreak line. The edges of the film are plugged to prevent moisture penetration from the outside.

- Laying the floor covering. Planks or slabs lie on the frame. A monolithic surface can be covered with commercial linoleum.

Similarly, the attic is insulated with perlite. According to its characteristics, it is slightly superior to expanded clay, but it has a higher cost.