Insulation of a frame house is one of the construction stages, which should be approached carefully and responsibly. Not only the level of comfort inside the building directly depends on this, but also the service life of the building itself. The advantages of such buildings are the speed of assembly, affordable cost and the possibility of construction at any time of the year. The downside is the insufficient level of thermal insulation. This drawback is easy to eliminate with your own hands. To do this, you need to study the properties of heaters, the technology of their installation, make the right decision and get to work.

Insulation requirements for a frame house

Shield houses are widespread in Finland, which is famous for its harsh climate. Similar weather conditions are often observed in Russia. Frameworks easily tolerate severe frosts, keeping them cool in the summer heat. This is achieved through the competent use of organic and synthetic insulation materials.

When making a choice, you need to focus on the following qualities:

- Durability. Fillers must maintain their performance throughout the life of the building. Otherwise, complex, long and expensive repairs will have to be done.

- Excellent ventilation properties. Materials are located in vapor-permeable structures that provide moisture removal from the premises.

- Ecological cleanliness. It is necessary to select a filler that does not contain substances harmful to human health.

- Low thermal conductivity. This characteristic determines the ability of a building to retain winter cold and summer heat.

- Constancy of form. If a material loses volume due to gravity, its performance will degrade over time.

- Lack of hygroscopicity. The accumulation of moisture leads to an increase in thermal conductivity, the development of mold and mildew.

When deciding which insulation is best for a frame house, you cannot be guided by its price. Only expensive and high-quality heat insulators can provide the comfort of living in a house for decades.

The choice of thermal insulation material

The construction market is replete with materials of the most diverse composition, configuration and scope. The rating of manufacturers is deservedly headed by the Knauf and Rockwool trademarks, whose products are distinguished by the highest performance characteristics. If you decorate the house with these insulation materials, you can forget about heat, dampness and cold forever.

To choose the right material, you need to familiarize yourself with the basic properties of the goods on sale.

Mineral wool

Mineral wool is a set of fibers oriented in space, woven into a dense and elastic fabric, the thickness of which is 5-20 cm.

According to its composition, mineral wool is divided into the following types:

- glass;

- stone (basalt);

- slag.

The products are delivered in rolls and mats.

Material advantages:

- environmental Safety;

- variety of shapes and sizes;

- ease of installation;

- low thermal conductivity;

- flexibility and resilience;

- fire resistance;

- good sound absorption.

Along with the advantages, mineral wool has minor disadvantages. It is hygroscopic and absorbs moisture well.An airtight exterior finish is required. When installed in the air, many microscopic fibers, hazardous to health, are released, which requires additional measures to protect the skin, eyes and respiratory organs.

Expanded polystyrene

Expanded polystyrene has proven itself in private and industrial construction. It is produced in the form of slabs 100 × 100 cm, thickness 50, 100 and 200 mm. Foam plastic is characterized by low density, consists of many porous balls welded together.

Material advantages:

- ease;

- ease of cutting;

- durability;

- affordable cost;

- waterproofness.

There are also disadvantages. PP is flammable and emits toxic fumes when ignited. The insulation is unstable to ultraviolet light and transmits sounds well.

Natural materials

Natural materials include:

- Expanded clay. The ball-shaped clay vulcanization product is characterized by light weight, environmental friendliness and low thermal conductivity. Despite this, it is rarely used, since it has a limited shelf life due to shrinkage and loss of performance.

- Ecowool. It is a split cellulose bound by lignin. It is applied by hand or using a special spray. The material is completely safe and has excellent thermal insulation properties. Due to its high hygroscopicity, it requires high-quality sealing.

For insulation, you can use sawdust, hay and peat mixed with clay. However, modern heaters are much superior to them in many respects, so these substances are practically not used.

Other heaters

The owner of buildings on screw piles is forced to solve the problem of isolating the supports. Foil-clad penoplex is best suited for this. The combination of a porous layer and metal provides heat retention inside and protection from outside cold. The downside is its fragility. Because of this, penoplex can only be used for finishing surfaces that are in the accessibility zone.

Polyurethane foam has proven itself well. In the process of spraying, the foam penetrates into all hard-to-reach places, after hardening it forms a dense and waterproof porous layer. The disadvantage is that it is expensive - you will have to use up a large number of spray cans for independent work.

Insulation types

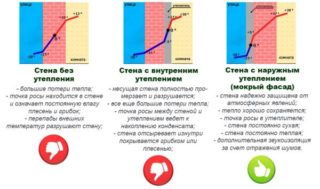

Internal

Such a decision is rarely made, since taking into account the thickness of the heat insulator, the volume of the premises is seriously reduced. In addition, external surfaces remain unprotected from the destructive influence of natural factors. The purpose of insulation from the inside is additional sound insulation from street noise.

The only plus is the convenience of work. It is much more convenient and safer to perform various actions under a roof, in a warm place and without wind.

Outdoor

The plus of insulation outside is that the dew point moves away from the supporting structures. Thanks to this, they are not affected by temperature drops, moisture and ultraviolet radiation. All this contributes to the extension of the service of knowledge and the creation of comfortable living conditions. In addition, the application of insulation and finishing on the outside can be done without any restrictions on their thickness. This is positive in terms of achieving optimal insulation and maintaining the interior volume of the rooms.

How to properly insulate the frame

When carrying out thermal insulation, it must be remembered that the frame structure must retain its ventilation qualities.Otherwise, it will have high humidity, condensation, which is an excellent environment for the development of pathogens. Achieving the desired result is possible only if all supporting structures are insulated - the floor, walls, ceiling and even the roof. In order for the work to proceed without complications, a scheme for laying materials on all external and internal surfaces should be made. On its basis, you need to make a calculation and purchase everything you need.

Walls and partitions

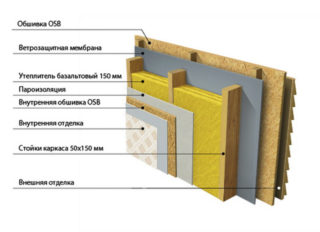

External insulation of frame walls is carried out in the following sequence:

- Thermal insulation of the strip foundation. For this, polystyrene is best suited, which is covered with facade plaster.

- Waterproofing. For this, coating or film technology is used. The choice is made based on the characteristics of the building, climate and own priorities.

- Creation of lathing from a wooden bar or steel profile. The mesh size is adjusted to the parameters of the insulation.

- Laying and fixing of heat-insulating fragments. This is done by installing them by elasticity or glue.

- Attaching the membrane sheet with a household stapler. The fabric provides one-sided moisture removal from the house to the street.

- Closing the frame with shields. To do this, OSB boards or plywood sheets are screwed to it. Then the shields are treated with an antiseptic and a primer.

- Finishing finish. Acrylic paint, curtain panels, lining and other products that allow air to pass through are used.

Another popular and widespread technology is the wet façade. When using it, the walls are sheathed with a solid waterproof material, on which insulation plates are glued. Then they are covered with a masking net, facade plaster and paint. The finished surface can be given any texture and color, effectively adapting it to the surrounding landscape.

From the inside, it is better to paste over the walls with penoplex, and then close them with plasterboard or natural wood slats. You should choose materials that are safe for health and do not emit harmful substances.

Floors

It is advisable to insulate the floor from below. This decision is justified by several reasons, the main of which is to reduce the usable space by raising the lower level. In addition, you will have to look for a floor finish, the top layer of which has the proper strength to withstand the weight of people and furniture without deformation.

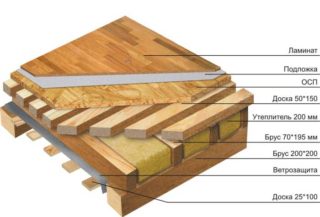

Step-by-step instructions for floor insulation:

- Laying rough boards on support posts. They must first be treated with a hydrophobic agent and an antiseptic. The remaining gaps are sealed with foam, sealant or tape.

- Laying a vapor-permeable membrane film. This fabric simultaneously functions as waterproofing and ventilation. Fastening is carried out with staples using a stapler. The strips are laid on 15-20 cm, the joints are fixed with tape.

- Creation of the lathing. It is made of boards 20-25 cm wide. The distance between them is chosen taking into account the width of the insulation, if you plan to lay plates of foam or mineral wool.

- Placement of thermal insulation in cells. Depending on the selected material, it is filled, inserted or blown into molds. If gaps remain, they are sealed with foam.

- Laying of finishing boards. Their thickness is selected so as to withstand the weight of objects pressing from above.

The final step is to apply the finishing floor covering. It can be varnish, paint, linoleum, parquet or carpet.

Ceiling

It is better to insulate the ceiling at the stage of the end of the walls, until the roof is erected.

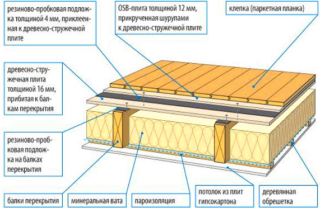

The event is held in the following sequence:

- A vapor barrier film is nailed to the beams from below.

- Sheets of plywood, OSB or boards are screwed on top of the film.

- Insulation is placed between the beams. The slots are sealed with one of the available sealants.

- A vapor-permeable film is stretched over the frame, the joints between the strips are sealed.

- The finishing coating is laid and fixed - boards or boards.

If insulation is carried out during operation, such a structure is attached from below to the existing base.

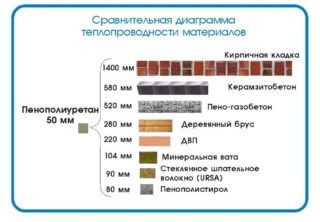

Insulation thickness

The average value for the middle part of Russia is:

- foam plastic - 100 mm;

- mineral wool - 150 mm;

- sawdust in clay - 40 cm;

- ecowool - 100 mm;

- expanded clay - 300 mm;

- polyurethane foam - 80 mm.

These are the minimum numbers. 10-25% should be added to them based on abnormal temperature fluctuations.