Harvesting season often lasts until the first frost. Staying overnight at sub-zero temperatures in an uninsulated country house is quite uncomfortable. The use of modern insulating materials allows you to independently reduce heat loss in the room. When insulating walls and ceilings, one should not forget that cold penetrates into the room from below through the floor covering.

Selection of materials and tools

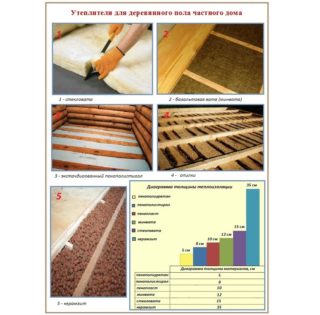

First of all, you should familiarize yourself with the technical characteristics of modern materials offered for insulation.

- Expanded clay - used as a backfill on a rough or concrete floor.

- Polyfoam - has good steam and thermal insulation. The only drawback is the tendency to crumbling.

- Expanded polystyrene and penoplex - have excellent thermal insulation qualities.

- Mineral wool - used quite often between the basement and the floor of the first floor.

- Ecowool - made from waste paper impregnated with antiseptic and fire retardants.

- Fibrolite is a mixture of wood fibers, water glass and cement. It is hygroscopic, therefore a waterproofing device is required. The recommended laying of the layer is at least 15 cm.

- Izolon - rolled polyethylene foam insulation. It has low thermal conductivity and good sound insulation.

- Penofol - insulation with a thin layer of foil that prevents heat loss. Resistant to heavy physical exertion.

No special tool is required for laying the thermal insulation, the material is easily cut with a sharp knife. A standard set of carpentry tools will come in handy for making the rough and final floor:

- mount;

- ax;

- a hammer;

- chisel;

- building level;

- saw;

- plane;

- screwdriver.

The use of electrical tools will significantly speed up the work. A small circular saw and screwdriver will be of great help.

Insulation of the subfloor

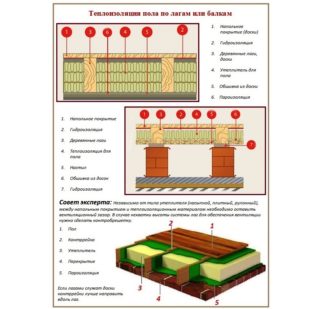

Roofing material or polyethylene film is used as waterproofing, which is laid on the subfloor between the logs. The edges of the film are folded, put on the logs and fastened with a construction stapler. The joints between the film are overlapped at least 100 millimeters.

Insulation is fitted and laid on the prepared surface. The easiest way to work with mineral wool, which has a loose structure, or with bulk components. Sheet thermal insulation requires a more careful fitting of joints or the use of polyurethane foam. The installed insulation should be flush with the top of the log or slightly lower so that it does not create an obstacle when installing the finished floor.

Before installing the floor, another waterproofing layer of polyethylene film is laid on top of the laid insulation to prevent moisture from entering from above. On the logs, floorboards are laid or a raised floor is mounted from plywood sheets or fibreboards under linoleum or laminate.

Thermal insulation on a wooden floor

Lay a waterproofing film on the flooring. On the prepared surface with screws, fix additional logs from a bar of 50x50 mm with a gap corresponding to the width of the insulation sheet, this will avoid unnecessary cutting of the panels. Expanded polystyrene has special joint grooves, on which a thin layer of polyurethane foam is applied immediately before installation, which ensures a tight connection against cold penetration.

On top of the installed insulation, a finishing layer of waterproofing is arranged. Depending on the intended finish, the installation of fiberboards or floorboards is carried out.

When using foam foam with a thickness of 10 mm as a heater, there is no need to install a bar. The material is laid directly on the wooden floor with the foil facing up. The seam of the stacked sheets end-to-end is glued with metallized tape. Plywood sheets are installed on top of the insulation and fastened with screws to the wooden floor. The finished floor covering is laid on the base.

Concrete floor insulation technology

Concrete has a high thermal conductivity and is a good cold conductor. To quickly and efficiently insulate the floor in the country house, made of concrete, modern technologies and insulating foam materials should be used.

A damper tape is mounted on the lower part of the walls around the entire perimeter of the room, which will compensate for temperature changes in the floor structure. The concrete surface is leveled with a small layer of mortar screed. On the leveled surface, panels of extruded polystyrene foam are laid in one or two layers, on top of which a polyethylene film is laid. Overlapping film joints with an overlap of 100-150 mm are carefully glued with tape. Next, a reinforcing mesh is laid and filled with a self-leveling solution. After the screed has hardened, the final flooring is laid.

When choosing a method of floor insulation in the country, one should take into account the technical condition of the existing coating, building structure, year of construction and other nuances. Undoubtedly, the easiest way, which does not require large costs and dismantling the coating, is insulation on a wooden floor, which is not difficult to do with your own hands.