Growing heating bills and disruptions in the work of utilities make people think about wall insulation with polyurethane foam, since it is rightfully considered the most effective option for solving the problem of heat and frost. The polymer material appeared on the domestic market relatively recently, but managed to gather a large army of adherents. If you have certain skills, you can apply it yourself. To do this, you need to purchase professional equipment and study the rules for spraying polyurethane foam.

Production technology and material application

Polyurethane foam is a polymer that has a porous or spongy structure. The main part of the finished substance is carbon dioxide, enclosed in open or closed cells with thin walls. Foamed polyurethane foam is produced by mixing together liquids, each of which has a static state. After the connection, a reaction occurs, accompanied by a violent release of carbon dioxide. As a result, the starting material increases in volume by 30-40 times and solidifies before air is released from it.

Warming with polyurethane foam is carried out using the following means:

- Household. They are ready-to-use aerosol cans with a capacity of 500-2000 ml. They are sold in hardware stores and are designed for local use in solving small construction and repair tasks. Household polyurethane foam insulation is used to seal large gaps after installing windows and doors, laying pipes, installing the floor and ceiling. To cover 1 sq.m. with a layer of 4 cm, one canister with a capacity of 1000 ml leaves.

- Professional. Thermal insulation of large objects with polyurethane foam is carried out using special industrial compressor-type equipment. PPU insulation is delivered to the place of work in sealed cylinders. After connecting to the compressor and setting the parameters on the control unit, pressure is supplied to the tank. The liquid components are fed through the hoses to the nozzle, where they are mixed. Installations are used for polyurethane insulation of walls of houses and engineering structures, foundations, pipelines and other objects of any size and configuration.

Thermal insulation of polyurethane foam is divided into types intended for application to steel, concrete, brick and wood. When placing an order or purchasing a PPU, it is imperative to take this feature into account. It is due to the fact that sprayed polyurethane foam has different properties in relation to strength and vapor permeability.

Varieties of polyurethane foam for insulation

The technical characteristics of the polyurethane foam are determined by the composition of the final product exiting the nozzle. By changing the proportions of the ingredients, you can achieve the desired foam properties for a particular object.

Lightweight open-cell polyurethane insulation is a soft material characterized by the following qualities:

- elasticity;

- flexibility,

- high hygroscopicity;

- ease;

- low density.

Foam rubber is used for the manufacture of pillows, mattresses, washcloths, linings for clothes.Lightweight PU foam insulation is used for thermal insulation of apartments from the inside, as well as a filler for containers for transporting fragile items.

Rigid closed-cell polyurethane foam, after hardening, forms a dense and solid porous substance resembling expanded polystyrene.

The material has the following qualities:

- hardness;

- strength;

- waterproofness;

- absorption of sounds.

The polymer has a wide range of uses. It is used to insulate residential and administrative buildings, engineering and agricultural facilities. Insulation is in demand in the manufacture of refrigerators and boilers, where it fills the internal voids of household appliances.

The most popular brands of polyurethane foam in our country are Polynor and Tepli, which have the best performance characteristics.

Pros and cons of using technology

When deciding how to insulate real estate, the owners are faced with a difficult choice: to use polystyrene, mineral wool, or to stop at polyurethane foam.

Warming a house with polyurethane foam gives the following advantages:

- Environmental Safety. Even the gas released during application does not pose any harm to humans and the environment. After hardening, the material becomes absolutely safe.

- Durability. Experiments on artificial aging made it possible to determine what the polyurethane foam will look like after 50 years of operation. As it turned out, its technical characteristics remained practically unchanged.

- The speed of application. There is no need for thorough preparation of the substrate and the use of adhesives. The composition has high adhesion, immediately and firmly adheres to any surface.

- Lightness meets durability. The material does not make the structures heavier and makes them stronger.

- Creation of a continuous coating layer. When expanding, the foam fills all gaps and voids. Lack of cold bridges and open joints.

- Wide operating temperature range. Polyurethane foam does not change its characteristics at temperatures from absolute zero to oven heat.

- Low thermal conductivity. This indicator is 4 times better than that of polystyrene and 2 times better than that of mineral wool.

- There is no need to use fasteners and frame structures.

Along with the pluses, the PPU also has its minuses.

- Destruction under the influence of ultraviolet radiation. To prevent the destruction of the material, it must be treated with paint, covered with plaster or decorative panels. Such measures are not needed underground.

- Smoldering under the influence of an open flame. During this process, carbon monoxide is released.

- Special equipment is required to insulate large areas. It is impractical to purchase it for a one-time promotion, and specialists ask a considerable price for their services.

Despite the high cost of the technology, it pays off in a few years, in the long term it gives a good profit due to efficiency and the absence of the need for periodic repairs.

What conditions are necessary for insulation with polyurethane foam

Insulation with polyurethane foam does not require special conditions, since this material is designed for use in a wide temperature and humidity range.

It is necessary to take into account the following nuances:

- The optimal value is the ambient temperature + 15-30 ºС. In the cold, the solution thickens and foams worse. In heat, it greatly increases in volume, which leads to the formation of a layer with reduced density and strength.

- No strong wind. Gusts can blow off foam, rip it off and crush on the base.

- Dry weather. Since buildings are insulated from the outside, foam should not be applied in a downpour. The water droplets will wash out the solution and make holes in the solidified surface.

- If filling frames or wall voids is carried out, the supporting structures must be pre-strengthened, as the foam can deform or break them when expanding.

- Use of serviceable equipment and experience in its operation. The effectiveness of the finished coating depends not only on the quality of the product, but also on the correctness of the settings.

When contacting specialists, it is recommended to study their resume in order to be sure of a positive outcome of the upcoming warming event.

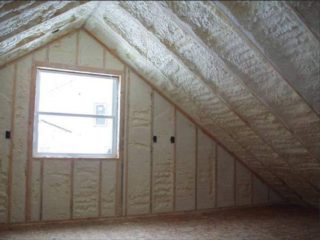

Do-it-yourself polyurethane foam spraying

The process of spraying polyurethane foam must begin with preparatory work. Although this material has excellent adhesion and corrosion resistance, a number of steps are required. Old paint, plaster, oilcloth and other materials should be cleaned from the surface, which can later come off the base and fall off along with the foam. It is necessary to remove all protruding metal fragments from the walls. They can become cold bridges and cause rotting processes in wood. It is also necessary to clean the base from oil stains, on which the polyurethane foam will not stick.

In the process of applying polyurethane foam, it is recommended to adhere to the following rules:

- Before starting work, cover frames, glass and door leaves with plastic wrap. Foam is extremely difficult to remove, even with the use of chemicals. It is imperative to use a mask and rubber gloves.

- Insulation should start by filling in hard-to-reach places and local areas - corners, joints of logs, channels for chimneys and ventilation.

- It is advisable to apply polyurethane foam continuously, moving the spray gun horizontally, gradually rising from the bottom up.

- The thickness of the layer is determined visually or by labels. You can apply no more than 5 cm at a time. The next spraying can only be done after the previously created one is completely dry. The optimal thickness of the insulation is 80-150 mm, depending on the climatic conditions of the region.

Additional finishing of polyurethane foam is not required, but immediately after hardening it must be protected from ultraviolet radiation.