The basement is an extension of the foundation that rises above the earth's surface. It connects the base and walls of the building, protecting it from moisture and cold penetration. For this function to be performed as best as possible, proper insulation of the base is important.

- Reasons and types of insulation of the basement element

- Materials used

- Styrofoam

- Extruded polystyrene foam (penoplex)

- Mineral wool

- Foamed polyurethane

- Expanded clay

- Do-it-yourself insulation technology

- Preparatory stages

- Subtleties of installing a heat insulator

- Features of thermal insulation of the pile foundation

- Finishing work

Reasons and types of insulation of the basement element

If the basement is not insulated, about 20 percent of the home heat goes through its walls. Competent thermal insulation helps to block the cold bridges, the material from which the building is erected does not freeze.

It is necessary to insulate the basement part in almost any house. Heat protection is not needed only if the private building:

- exclusively for seasonal use;

- not equipped with a basement, and the basement element is not higher than half a meter and is equipped to protect against groundwater;

- is located in a region with a mild, warm climate.

In these cases, it is enough to insulate the floor covering. But if the area is famous for harsh winters, they live in the house all the time, and groceries are stored in the basement, a garage, boiler room or other utility rooms are equipped, heat protection is necessary.

The basement element is insulated from the inside and outside.

Internal thermal insulation provides only minimal protection from the cold. At the same time, moisture condenses between the wall and the insulation, destroying the building material. In addition, the outer layer will be exposed to cold winds, which will lead to the formation of microscopic cracks that will expand in the cold. As a result, the walls of the base will begin to crumble and deform.

When insulating the basement floor, the inside space and the basement itself will be protected from the outside: the dew point will shift to the heat insulator layer, which is not afraid of moisture and frost. The cold bridges will be blocked, the outer walls will be protected not only from precipitation and freezing, but also from mechanical damage. The house will not require repairs any longer.

If financial possibilities permit, it is worth making a comprehensive thermal protection, if not - only external.

Materials used

To insulate the basement of the house from the outside, select insulators that retain heat well, are not afraid of moisture, and are resistant to the development of fungus and mold, rodents and insects, such as ants. But even popular materials have their drawbacks that need to be considered.

Styrofoam

The most inexpensive option for basement insulation. It comes in different thicknesses. This allows you to select the right sheets for the desired climate zone. For example, for the middle strip, it is better to select plates 8-10 cm thick.

Polyfoam has the following advantages:

- budgetary cost;

- low weight - the foundation does not need to be strengthened;

- ease of installation using special fasteners, glue or mastic.

Styrofoam burns and releases toxic substances. It is easily gnawed by mice. He is also afraid of moisture and ultraviolet radiation, therefore, requires cladding.

Extruded polystyrene foam (penoplex)

The most popular heat insulator for basement floors.Expanded polystyrene is similar to polystyrene, but since it is extruded, the PP gains additional rigidity and strength, holds the pressure of the earth well, and is resistant to crushing and subsidence.

Insulation of the basement with penoplex has many advantages:

- low degree of thermal conductivity;

- resistance to moisture and fire;

- soundproofing properties;

- high compressive strength;

- the operational period is more than half a century;

- ease of installation;

- budget cost.

The building material is not interesting to rodents, it does not grow moldy.

Before you insulate the basement of the house from the outside with your own hands with penoplex, you need to take into account: even from the dimensional sheets of EPSP it is impossible to create a completely monolithic structure, the seams require careful covering and foaming. To reduce gaps, it is preferable to use interlocking plates with a tighter joint, which reduces the risk of cold bridges. You need to cut the sheets carefully so that they do not crumble.

Mineral wool

Basalt mineral wool is suitable for thermal insulation of basement floors. The use of building material in rolls allows you to get a minimum of joints, and the slab version is considered more durable.

Heat insulator advantages:

- increased heat-shielding and noise-insulating properties;

- fire resistance and vapor permeability;

- immunity to mold;

- long service life;

- easy installation.

Mineral wool accumulates moisture, which reduces the thermal insulation properties, therefore, waterproofing is required during installation.

Foamed polyurethane

The application of the insulating layer is carried out using specialized installations on a previously cleaned and leveled surface. This option is not cheap, but provides maximum thermal protection due to bubbles of carbon dioxide, which conserve heat.

Other advantages of foamed polyurethane include:

- fills in all cracks, depressions and joints;

- does not imply the presence of seams;

- durable yet lightweight;

- tough but elastic;

- repairable - the damaged area can be easily closed with a new portion of polymer;

- applied extremely quickly.

For insulation with polyurethane foam, you need to hire specialists with professional equipment. The processed base will require finishing, since the material is destroyed by ultraviolet radiation.

Expanded clay

Lightweight, eco-friendly and inexpensive material. Due to the porous structure of the granules, good heat and sound insulation is ensured. Expanded clay is not afraid of fire, weighs little.

Granules absorb moisture well, therefore, drainage will be required. In addition, bulk insulation must be installed using formwork, which will take a lot of time.

Do-it-yourself insulation technology

Ideally, work on the thermal insulation of the basement is carried out at the stage of construction of the building. The commissioned building can also be improved, but somewhat more complicated. The technology depends on the type of foundation.

Preparatory stages

First of all, you need to calculate the amount of material - how many square meters. m of insulation will be required. To do this, it is easier to use the building drawings, add a margin of 15 percent to the resulting figure.

The tape base is insulated simultaneously with the underground part. If this is not done during the construction of the structure, you will have to bare the foundation by digging a trench to the bottom. After that, you will need to lay the waterproofing and insulating layers so that they capture the surface of the base and base.

Subtleties of installing a heat insulator

For fixing polystyrene or expanded polystyrene, it is better to choose a specialized glue. Bituminous mastics include chemically aggressive substances that can damage the insulating material.

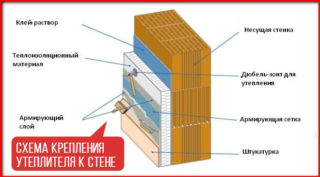

To fix the heat insulator to the basement surface above the ground, use adhesives or hardware - umbrella dowels. Mechanical fastening is necessary here: without soil support, only the adhesive layer will not be enough to securely hold the material.

When the heat insulator is fixed on the entire foundation and basement surface, backfill is performed and a blind area is created, which, if the soils are heaving, must also be insulated.

Features of thermal insulation of the pile foundation

Thermal protection from the inside is installed if a basement or a cap is created by sheathing pile columns on a frame made of wood or metal.

When erecting a building on a pile foundation, it is often necessary to insulate the gap that remains between the earth's surface and the overlap of the first floor. This is especially necessary if the communication lines of the building are located in this node.

Finishing work

Insulated basement does not always require cladding. For example, if thermal panels are used. They already have a layer of finishing: you can choose options that imitate wood or stone coating, brickwork. But the pleasure is not cheap.

For thermal insulation with foam or expanded polystyrene, plaster or tile is often used. Finishing work begins with the fact that the boards are covered with a layer of adhesive, into which a reinforcing fiberglass mesh is pressed. It is also covered with glue, the surface is leveled. When it dries, the plinth is plastered or refined with tiles.

Thermal insulation with mineral wool will require a curtain facade. He is planted on a lattice frame made of a metal profile. To avoid cold bridges, the brackets are foamed. Sheathing the crate with moisture-resistant panels, siding. For other types of insulation, this option is also suitable.

The selection of an insulator for insulating the basement floor depends on the financial capabilities of the owner of the house and climatic conditions. If the insulation is chosen correctly, a comfortable microclimate will be created in residential and basements.