Central heating does not always cope with the tasks assigned to it, and autonomous heating will cost too much if energy saving measures are not taken. Insulation of a concrete floor in a private house or city apartment will help reduce the cost of heating the premises, create a healthy and comfortable microclimate in them. If you have a set of household tools and experience in handling them, you can insulate the concrete floor with your own hands, saving a considerable amount on hired workers. The key to success is the correct choice of material and technology for thermal insulation.

Types of thermal insulation materials

The construction market is saturated with products that differ in appearance, composition, scope, price and performance.

In order not to be mistaken when buying, you need to decide on the following nuances:

- place of work - balcony, balcony, sauna, garage, apartment, private house;

- the purpose of the event is to make insulation or install a heating system;

- thermal insulation method - internal or external;

- room heating schedule - constant or periodic;

- the budget allocated for repairs.

When choosing a material, it is necessary to pay attention to the restrictions that apply to residential and commercial buildings.

Mineral wool

Minvata is an ideal insulation for concrete floors in terms of technical characteristics. On the construction market there are rolls and mats made of glass, slag and dolomite stone. Basalt wool Technonikol has the best qualities in all respects, but its price is also the highest. A feature of the material is its hygroscopicity. To avoid moisture swelling, membrane fabrics are used that remove steam from the insulation. The elasticity of the mats is used when laying them in the frame. This avoids the formation of cracks and additional work to eliminate them.

Styrofoam

Polyfoam has a long and successful history of use in industrial and private construction. It is produced in the form of plates 100x100 cm in size with a thickness of 20-200 mm. The slabs consist of a plurality of pressed white balls with a porous structure. The material is distinguished by the lowest cost among analogues, low density and thermal conductivity. It should be borne in mind that PPT absorbs moisture, which leads to the destruction of its structure. In addition, insects and rodents like to settle in the foam, so it must be well insulated.

Extruded polystyrene foam

Penoplex is a modification of polystyrene with higher performance characteristics. Open cells allow steam to pass through the slabs, making them more versatile. The stepped edges of the slabs ensure a tight, seamless connection of the fragments in the masonry. Expanded polystyrene is resistant to moisture, temperature extremes and is designed for 50 or more years of service.

Polyurethane foam

Spray foam appeared on the construction market relatively recently, but managed to win a large army of adherents. Products are categorized into household and industrial categories. The first includes aerosol cans with a volume of 500-2000 ml, sold in hardware stores.Industrial foam is applied to objects using special compressor equipment and a spray gun. Getting on the base, the suspension foams, increasing in volume 30-40 times. At the same time, the substance fills all voids and openings, creating a seamless monolithic surface. The material has excellent insulating properties, environmental safety and durability.

Expanded clay

Expanded clay is porous granules obtained by vulcanizing a mixture of clay and limestone. Bulk thermal insulation is characterized by low thermal conductivity and affordable cost. To achieve the required filling density, part of the granules is crushed and then added to the whole fragments. This eliminates cavities that contribute to vibration shrinkage. It is necessary to take into account the disadvantages of the material: over time, it swells with moisture and decreases in volume under its own weight. Because of this, it has to be replaced every 3-4 years.

Foam glass

Foam glass is a porous plate with many open cells. In its manufacture, the property of glass is used to foam at temperatures above 1000 degrees. Finished products are durable, environmentally friendly and have low thermal conductivity. The material is impervious to moisture, chemically active reagents and temperature extremes. Rodents and insects avoid it.

Foam glass does not burn and is not susceptible to mold. The coating is hard and durable and can be covered with laminate using only an intermediate backing.

Bung

Cork is a natural environmentally friendly material that is resistant to moisture and temperature extremes. It is produced in the form of slabs up to 2 cm thick and up to 100 cm wide. The cork has a low thermal conductivity, density and a relatively strong surface. The disadvantage is that the substance attracts rodents and insects, which can spoil it with their waste products.

Perlite

Expanded perlite sand is characterized by chemical and biological inertness, moisture resistance, high and low temperatures. Made from volcanic rock and therefore inexpensive. Perlite is poured between the logs, after which it is rammed.

Material selection criteria

Floor insulation for a concrete slab must meet the following criteria:

- low thermal conductivity;

- minimal hygroscopicity;

- immunity to temperature extremes;

- environmental Safety;

- resistance to decay, fungus and mold;

- affordable cost;

- the ability to do it yourself.

If one of the qualities does not meet the set of requirements, it can be compensated by installing protective or ventilation layers.

Methods for insulating a concrete floor

It is possible to insulate a concrete floor in a private house in various ways, choosing the most suitable method for specific conditions.

During construction, this event is best done before the rough screed. This method will allow you to move the dew point away from the foundation, while protecting it from moisture and contact with alkaline soil. Before pouring the mixture on the ground, you can lay plates of foam or expanded polystyrene. Another option is to backfill expanded clay or perlite, which is covered with cellophane film.

Insulation of the concrete floor of the first floor in a private house during the pouring of concrete is carried out on top of a slab located above a cold basement. This approach allows you to isolate the living space from the cold and prevent the cellar from heating up, which is used for long-term storage of food. It is better to insulate the floor with an inexpensive PPT, 5 or 10 cm thick, depending on the climate. The cured coating is the basis for the finishing. You can immediately lay linoleum, tiles, engineering or wooden boards on a warm floor.

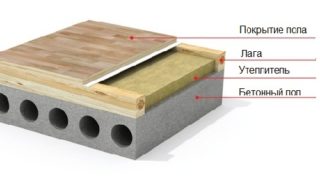

If the height of the ceiling allows, insulation is carried out on top of the concrete slab by creating a lag system.The scheme is drawn up so that the floor covering can be laid on the frame without unnecessary scraps.

Warming process

There are two technologies, different in content and end result, with which you can effectively insulate the floor in a residential building. The choice depends on its configuration and the available material.

The dry method is performed in the following sequence:

- Installation of waterproofing is in progress. It is necessary to protect the structure from the moisture that comes from the concrete. A film, roofing material or a coating composition is selected.

- A frame made of boards is fixed on the slab. They are pre-dried, treated with an antiseptic and a hydrophobic composition.

- Insulation is added to the inside of the frame. The foam is blown out flush with its edges, the cotton slabs are inserted into the hole, the bulk material is compacted.

- A membrane sheet is nailed onto the logs. The edges of the strips are glued together with tape.

- Sheathing is laid. It can be chipboard, OSB, a block house under a polished board.

The wet method consists of the following stages:

- Sub-floor waterproofing.

- Attaching insulation boards to it. The material is staggered and glued to the base. The edges of the slabs are twisted with self-tapping screws.

- Reinforcement cage is made and laid.

- A damper tape is glued around the perimeter of the room.

- The solution is mixed and the screed is poured.

- After drying, the floor surface is leveled and primed.

The final stage is the installation of the finishing cladding.