In most of the territory of Russia in the autumn-spring period, the temperature conditions are uncomfortable for life. The constant rise in the price of energy resources makes it necessary to improve the energy efficiency of residential buildings, baths, and outbuildings. The international corporation Technonikol offers a full range of building materials for insulation and waterproofing of any buildings and structures. Based on the tasks and operating conditions, they choose Technonikol basalt insulation or extruded polystyrene.

- About the manufacturer

- Basalt insulation

- Appointment

- How and what is it made of

- Specifications

- Advantages and weaknesses

- Mounting options

- Installation of a "wet facade"

- Insulation with roll materials

- Insulation of the roof and ceiling

- Extruded polystyrene

- Purpose and places of use

- Raw materials and manufacturing method

- Technical specifications

- Advantages and disadvantages

- Installation of polystyrene

About the manufacturer

Technonikol Corporation owns 54 factories in Russia and 6 European countries (Czech Republic, Germany, Great Britain, Belarus, Italy, Lithuania).

6 research centers are engaged in the development of testing and long-term testing of the assortment.

The quality of our products meets safety requirements, which is confirmed by certificates.

Thermal insulation materials made of basalt and polystyrene are popular due to their characteristics, easy installation and range of products suitable for any operating conditions.

Basalt insulation

TechnoNIKOL mineral wool is produced in the form of rolls and slabs. The production technology of the products is the same, but they have different densities. This is taken into account in design and construction, the choice of installation technology and finishing.

Appointment

Dense stone wool TechnoNIKOL in the form of slabs allows the effect of mechanical stress. The main direction of use is insulation of building walls. Installation is carried out using the technology of a wet facade (under plaster) or under cladding clapboard, tiles, panels (ventilated facade).

Due to their structure, the slabs retain heat and serve as sound insulation and fire protection.

How and what is it made of

Mineral wool Technonikol is made from basalt rock with synthetic binders and special additives that improve hydrophobic properties and prevent combustion.

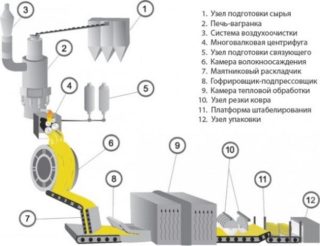

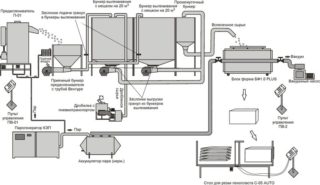

During the production process, basalt goes through several stages of processing:

- The rock is cleaned of impurities and crushed to a fine fraction.

- Raw materials are melted in a high-temperature furnace.

- The molten mass is mixed with additives in a centrifuge, where decomposition into individual fibers occurs simultaneously.

- The fibers are mixed by the flow of compressed air, the structure of the arrangement becomes chaotic.

- Cooling of the resulting mass.

- Pressing on the conveyor of several layers.

- Heat treatment in which the additives polymerize.

- Cutting to the required dimensions.

The entire technological process takes place without interruption, thanks to which TechnoNIKOL mineral wool becomes durable, resistant to temperature loads and other adverse factors.

Technologically, the production of slabs and rolls is no different, but the finished product has different densities, therefore, different installation schemes are used when insulating walls, ceilings and roofs.

When buying, check the security certificate.Counterfeit and counterfeit products often contain unacceptable amounts of phenols, and the basalt itself can be radioactive.

Specifications

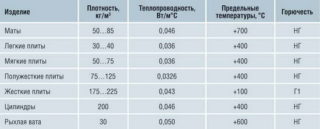

The corporation produces several dozen product names.

When buying, pay attention to the parameters of the Technonikol mineral wool insulation:

- Low thermal conductivity is achieved due to the randomly located fibers and the airy structure of the material. The parameter ranges from 0.032 to 0.05 W / (m * K).

- Vapor permeability contributes to the fact that condensation does not accumulate in the insulation - vapors move freely from the walls into the surrounding space, and the material does not get wet. On average, the indicator is 0.3 mg / (m * h * Pa).

- Hydrophobicity - the ability not to absorb moisture from the surrounding air, not to get wet in damp rooms. Different types of TechnoNIKOL thermal insulation absorb from 2 to 5% moisture from their own weight. For damp rooms, products with a minimum indicator are chosen.

- Soundproofing the TechnoNIKOL minelite reduces sound from shock loads (low frequencies up to 300 Hz), but is not very effective against street noise in the upper frequency range. Solution for noisy places - Technoflor Standard slabs and Technoacoustic rolls.

- Thickness directly affects thermal insulation properties. Plates are produced in thickness from 50 to 200 mm, in rolls up to 70 mm.

- The length of the roll is up to 10 m and the width is up to 1.2 m, the geometrical dimensions of the slabs are up to 1200 mm wide, and the height up to 1000 mm.

- Environmental friendliness complies with EU standards. The maximum content of organic matter (including phenol) in TechnoNIKOL slabs is not more than 4.5%.

- The density of materials is from 35 kg / cubic meter. m for the Rocklight line up to 190 kg / m3 at Technoruf. The parameter is important when choosing a mounting method.

- Working temperature from -60 to 190 ° C.

Products with low density are prone to caking, therefore they are not used for insulation of horizontal surfaces.

Advantages and weaknesses

Product advantages:

- low thermal conductivity compared to other materials;

- non-flammable material;

- environmental friendliness;

- air and vapor permeability;

- resistance to deformation;

- wide range of permissible temperatures;

- does not rot, is not damaged by rodents and insects;

- service life up to 50 years;

- relatively low cost with high insulation rates;

- ease of installation that does not require expensive fixtures.

A significant disadvantage is the caking of low-density products.

To eliminate cold bridges, special attention is paid to the processing of seams - roll models are laid with an overlap, the seams between the plates are sealed with polyurethane foam.

None of the types of insulation can be left without a decorative layer - in direct sunlight and when exposed to precipitation, the material gradually collapses.

Mounting options

For the version with plastering, slabs with a density of at least 130 kg / m3 are suitable - they usually have sufficient peel strength.

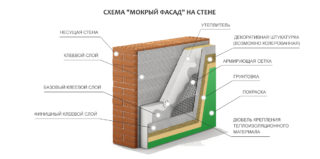

Installation of a "wet facade"

The initial stage of “wet facade” insulation is cleaning the wall surface from dust, dirt, oil stains, etc.

The gaps in the masonry are sealed with plaster mortar and the irregularities are maximally smoothed. Depressions of no more than 3 cm per 1 linear meter of the wall are allowed.

Further, there are two options for mounting panels: on glue or only with dowels with a wide head (fungi). In the first, glue is applied to the wall and slab and the mixture is leveled with a notched trowel. Insulation TechnoNIKOL for walls is pressed against the wall for a few seconds. For greater strength and in order not to wait for the mortar to set, the plates are reinforced with dowels of the required size. Within a day, the glue dries up and proceeds to further finishing.

When fastening only with dowels, a layer of vapor barrier material is laid between the wall and the insulation plates. Joints and seams are sealed with polyurethane foam.

The next step is the application of the first layer of plaster. A special glue is used for the mixture. The first layer is applied, into which the plaster mesh is embedded.

The mesh and the glue must match - some mesh models dissolve in an alkaline environment. Reinforcing mesh is chosen for outdoor use.

Smooth the composition. After the first layer has completely dried, the main plaster is carried out. To give the surface an attractive appearance, decorative plasters are used, which are subsequently painted.

Insulation with roll materials

The first stage is cleaning and leveling the surface on which the vapor barrier is nailed.

A crate is nailed on top of the vapor barrier. The step of the longitudinal and transverse lags should allow a tight fit of the insulation for the TechnoNIKOL facade. Roll material or slabs are fastened with dowels with wide heads.

Next, a layer of windproof film is nailed to the lags with a stapler, on top of which a counter-lattice 1 cm thick is mounted. The design is needed so that there is a gap between the waterproofing and the finishing coating for ventilation and evaporation of moisture from the thermal insulation.

The final stage is the installation of finishes, which are used as ceramic tiles, plastic or wooden siding, and other options.

Insulation of the roof and ceiling

Thermal insulation of a horizontal surface is possible in two ways.

In the first case, a vapor barrier membrane is laid on the floor slabs, a layer of dense (from 150 kg / m3) mineral wool. A cement-sand mortar is screed on top of the insulation.

The second option is fully consistent with the "ventilated facade" technology. The pie is mounted: a vapor barrier, insulation between the logs, a waterproofing membrane, a counter-lattice, a finishing layer of OSB panels, plywood, chipboard or floorboards.

If the attic is not intended for people to be there, the final floor is not laid.

Inclined roof slopes should be performed using ventilated facade technology.

Extruded polystyrene

The assortment of Technonikol corporation includes extrusion polystyrene.

Purpose and places of use

The material is produced in the form of slabs and has improved thermal insulation and strength characteristics. This allows it to be used at various stages of construction.

Insulated with expanded polystyrene:

- walls, floors, ceilings of buildings;

- roofing and attics;

- basement and basement walls;

- blind areas.

Polystyrene is a good sound insulator and can be used in interior partitions.

Raw materials and manufacturing method

The material for production is polystyrene granules, which are produced by the chemical industry from petroleum products.

In industrial lines, polystyrene is heated to the melting temperature and fed to the extrusion head by screw devices. Under the action of hot steam and high pressure, the polystyrene is foamed, after which it is fed to the forming line, where it is flattened.

After the secondary foaming, the mass is formed on stretching machines, and after cooling, it is cut to the required size.

As a result of extrusion, a material is obtained that consists of many air bubbles, enclosed in an individual shell. The shells are tightly welded to each other, which makes the extrusive polystyrene waterproof and poorly absorbing moisture - all places of possible penetration are closed for it.

The Technonikol company uses carbon granules in the production of polystyrene boards, which is why the peculiarity of the products of this manufacturer is a silvery color - this is one of the signs that the products are not fake.

Technical specifications

Extrusive polystyrene parameters:

- thermal conductivity 0.029 - 0.031 W / (m • K);

- water absorption - 0.2% by volume;

- vapor permeability - 0.014 mg / (m • h • Pa);

- operating temperature - -70 - +70 ° C;

- thickness - from 30 to 100 mm;

- length 1180, width 580 mm.

You can carefully walk on the polystyrene laid on a horizontal surface - the dents that appear will disappear after a short period of time.

Advantages and disadvantages

The positive and negative properties of a material are directly related to its structure and technical characteristics.

The advantages of products include low thermal conductivity, compression resistance, incombustibility. The material does not rot and does not support the spread of mold and mildew.

The absence of cavities and moisture in the material makes it resistant to negative temperatures - styrene foam does not freeze.

I consider the negative aspects of the low vapor and air permeability of the plates.

Low weight ensures ease of installation - sheets can be easily lifted to any height, and reliable brackets are not required for fastening.

High extrusion properties of the material provide reliable adhesion to the plaster.

Polystyrene is produced with grooves and with careful installation there are no cold bridges.

The disadvantages include:

- destruction from sunlight (ultraviolet radiation);

- high price;

- the release of harmful substances when heated;

- possible colonization of rodents.

The whole complex of positive and negative qualities is taken into account when choosing extruded polystyrene as thermal insulation.

Installation of polystyrene

A feature of polystyrene is the possibility of its use for insulating the underground part of buildings and blind areas around buildings.

To arrange the blind area, a clay castle, a layer of sand, and polystyrene are laid in layers. The finishing layer is a cement-sand or concrete screed.

When insulating the ceiling ceiling, it is allowed not to use a vapor barrier membrane, since the low vapor permeability of the material makes vapor barrier meaningless.

The correct choice and installation of thermal insulation materials produced by TechnoNIKOL Corporation will save heat in the house in cold weather and keep it cool in summer. It is important to follow the installation technology so that the coating will last for many years.