The Russian climate is characterized by harsh winters and cold off-season periods. This involves the arrangement of private houses, summer cottages, cottages and baths with autonomous heating systems. An integral part of these structures are structures designed to remove fuel combustion products. The efficiency of the boiler and the safety of the entire building depend on the competently performed insulation of the chimney. You can complete this task with your own hands, saving on the services of professionals. You just need to choose the right insulation for chimneys and the most suitable technology for its installation.

Prerequisites for the destruction of the chimney

The exhaust pipes of combustion products are subjected to extreme tests associated with exposure to chemically active substances, temperature and humidity changes.

In the absence of high-quality thermal insulation, the chimney quickly collapses under the influence of the following factors:

- The combustion of fuel is accompanied by a large amount of heat, which acts on the walls of the branch pipe. If they are not protected by insulation, condensation forms on the inner surface. Moisture is absorbed into the brick and seams, expands when freezing and tears the masonry.

- The creosote deposited on the pipes is dissolved by water and turns into a chemically active substance with an increased level of acidity. The solution is corrosive to metal and can erode it through and through in just one season. Even stainless steel cannot resist such a caustic substance.

- A dense oily coating gradually accumulates on the walls of the pipe, gradually overlapping its cross section, until it is completely closed. Lack of traction is fraught with carbon monoxide poisoning of residents.

- The gas outlet running through the roof heats the roof and rafters. There is a high likelihood of a fire, especially when deposits accumulated in the pipe flare up.

The use of modern insulation for chimney pipes minimizes the risk of fire and ensures more efficient operation of the heating system.

Positive aspects of chimney thermal insulation

If you insulate a chimney metal pipe with your own hands, you can forget about cleaning, replacing and even maintaining it for many years. A high-quality construction works smoothly and without any complications.

The pipe insulated for the chimney has the following advantages:

- No moisture builds up in the duct. Due to this, chemically active elements do not linger on its walls, but freely fly out into the street or settle in the filter (on the visor).

- The inner surface of the pipes remains clean and smooth. Traction is always good and stable. There is no need to carry out time-consuming and dusty cleaning of the canal.

- Insulation for the chimney blocks the heat passing through it. The outer walls remain cold, which helps preserve the integrity of the roofing material, eliminating the risk of fire.

- Increasing the energy efficiency of the oven. Energy is not used to evaporate moisture and burn off deposits. Fuel consumption is reduced whether gas, wood or coal are used.

- Providing additional stability of the highway.Thermal insulation for chimney pipes acts as an additional frame, protecting the duct from wind load.

Do-it-yourself chimney insulation involves the application of certain efforts, the cost of effort and money. However, this is a profitable investment that will pay off in the shortest possible time in terms of finances, increasing the level of comfort and safety of living in the house.

Insulation materials

The choice of material for the insulation of the chimney should be approached thoughtfully, paying attention to every little thing. The construction is designed for a long time of operation, it is necessary to take into account all the nuances during planning and installation.

Insulation must meet the following requirements:

- incombustible;

- thin;

- heat resistant;

- impervious to moisture;

- durable;

- biologically inert;

- easy to use;

- easy;

- retaining its shape and volume;

- environmentally friendly.

The required materials are produced in the form of slabs and mats, roll, sheet and loose form.

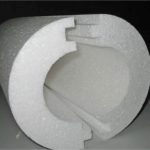

The best technology for insulating chimneys is considered to be a heat-insulating steel cylinder filled with insulating material. The product consists of two iron pipes of different diameters connected together, where the smaller one serves as a channel for the removal of combustion products, and the upper one serves as a fence for insulation.

For manufacturing, stainless steel is used, resistant to high temperatures and mechanical stress. To further reduce the thermal conductivity, an asbestos cord is wound on the outside of the casing. The pipeline is connected to the nozzle of the furnace boiler and is led out to a height of at least 100 cm above the roof.

The following materials can be used as a filler:

- Expanded clay. It is a product of clay vulcanization, it is a hollow brown balls. To achieve a higher density, a mixture of whole and crushed granules is poured into the opening. The filler has low thermal conductivity, but is prone to shrinkage and moisture absorption. High-quality waterproofing of the chamber joints is required.

- Basalt wool. Stone mineral wool is considered the best heat insulator, which has a full set of technical characteristics necessary for the construction of furnace systems. The mineral filler is non-flammable, perfectly retains heat, and is resistant to decay and dampness. The downside is the selection of small fibers during installation. It must be performed in protective equipment for the skin, eyes and respiration.

- Expanded polystyrene. It is possible to insulate pipes with a material with a flammability class G2, which can withstand heating up to + 600 ° C. This category includes such EPPS brands as penofol and penoplex. Fastening of the material to the iron is carried out with the help of refractory glue, the gaps are sealed with trim strips.

- Penoizol. It is one of the types of polyurethane foam with zero secondary expansion. After cooking, it is poured into a sleeve using a sleeve, where it hardens for 2-3 days. The hardened mass outwardly resembles foam plastic, but surpasses it in insulating qualities and does not decompose when heated.

- Ceramic plaster. The mortar can be used for interior filling and exterior decoration. The cured substance has excellent protective properties and is resistant to heat and moisture.

It is not enough to choose a good insulation, you also need to correctly assemble the chimney. To do this, you should familiarize yourself with the nuances of this process.

The subtleties of self-insulation of the chimney

If you plan to use a gas boiler to heat the house, entrust its installation, connection and adjustment to specialists. The manufacture of a chimney can be done independently, with the usual set of household tools.

When doing this work, you should take into account the following nuances:

- Thermal insulation must be applied in a continuous and uniform layer. Gaps are heat bridges that cause condensation.

- Docking of double pipes must be carried out so that the lower section enters the socket of the upper product.

- If a membrane sheet is used, it must be fastened so that the inscriptions are on the outside.

- External insulation is carried out after the channel is removed and fixed. Internal insulation is done during construction.

- If the roof is lined with a combustible coating, a spark arrester must be installed on the chimney head.

- It is imperative to install a visor. This inexpensive product protects the canal from dirt, birds, small animals and debris.

- The insulation layer must be thick enough to reliably block the oven heat. For basalt wool, you need at least 4 cm, glass and slag - 5 cm, foam fillers - 6 cm, expanded clay - 8 cm.

Correctly carried out thermal insulation of the chimney affects the high-quality removal of combustion products and prolongs the service life of the heating system.