To heat personal dwellings and supply them with hot water, it is important to learn how to choose a boiler for heating for a private house, allowing it to be used in an autonomous mode. To do this, you will need to deal with the existing varieties of units of this class, as well as with all the intricacies of their operation. Before purchasing the equipment suitable for specific conditions, it is advisable to study the main characteristics of these products, on the basis of which it will be much easier to choose the right sample.

Main selection criteria

There are many models of heating boilers on the market for a house of various classes. By the type of fuel used during operation, they are divided into the following types:

- solid fuel boilers for home: on wood, peat, pellets or coal;

- units that use liquid fuel in their work: diesel fuel, for example;

- gas boilers;

- electric heating devices that allow you to do without fuel;

- universal products that run on gas or pellets or consume firewood and electricity.

Before choosing the appropriate option, you should carefully study the list of energy carriers and decide which ones are more suitable for specific operating conditions.

It is necessary to determine how good the boiler is in terms of operational safety, as well as comfort when handling it. When choosing a unit suitable for personal needs, you will need to take into account the following nuances:

- thoroughly understand the advantages and disadvantages of each of the presented samples;

- determine the optimal power of heating equipment for specific conditions and the number of circuits;

- choose a place in the house where you can put the purchased equipment.

The last factor determines the permissible dimensions and weight of the purchased sample.

For small premises in a country house, choosing a heavy cast-iron unit is impractical.

Power calculation procedure

The desire to save money on the purchase of a heating system of suitable energy intensity, as a rule, turns into even higher costs. To avoid troubles will help to seek help from professionals who are able to correctly calculate the required power of a heating boiler for a private house and its other parameters. This approach will cost the user much less.

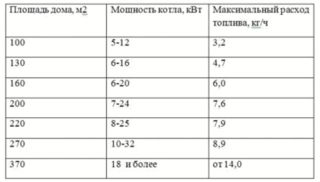

The power of the boiler equipment is selected on the basis of its consumption of 0.1 kW per unit of living space.

For its approximate calculation, you can use the practically obtained standards, when introducing which the following factors were taken into account.

- the number of residents living in the house;

- the type of material used in the construction of the structure;

- the climatic zone in which it is located;

- the total number of windows and doors;

- number of storeys of the building.

Due to the use of modern insulation materials and the correct selection of heating equipment, heat loss in a number of cases can be reduced to a minimum.

Boiler characteristics

Well-known models of boilers for heating a house differ in design, cost and fuel used during operation. Their characteristics are directly related to the type of energy carrier.

Solid fuel boilers

Solid fuel, according to a long-standing tradition, is considered the most accessible and cheapest of all possible, which explains its great popularity.

In solid fuel boilers, it is allowed to burn only the type of energy carrier for which they are designed. This can be firewood, peat chopped into pieces or chopped coal, but not the remains of unnecessary garbage. The advantages of these pieces of equipment include:

- full autonomy;

- low cost of energy;

- sufficiently high efficiency (efficiency).

The only inconvenience that cannot be avoided when working with such boilers is the need to add fuel all the time. This is the only way to ensure long-term and efficient operation.

Features of pellet boilers

Typical wood pellets called “pellets” are wood waste compressed into a small cylinder. They are formed under a pressure of 300 atmospheres. Their dimensions are 6-10 mm in diameter and 10-30 mm in length. The essence of the operation of the pellet boiler is to load them into the furnace from a small attached hopper equipped with a screw feed mechanism.

The fuel stored in such a container is usually enough to heat the house for several days. The efficiency of solid fuel boilers is slightly higher than the same indicator for pyrolysis equipment. The relative disadvantages of this type of fuel include its fast combustion and high cost.

Oil, gas and electric boilers

Oil fired boilers are known for being simple, reliable and economical diesel fueled designs. But they, like any equipment with an open burner, have many disadvantages, including noise, unpleasant odor and high fire hazard. Therefore, many users prefer gas units, which also save on the cost of the fuel itself.

Electric boilers are usually chosen as a temporary measure - they are used until the gas main is connected to the suburban area. Their purchase in all other cases is considered impractical, since the cost of electricity only grows from year to year.

Universal boilers

Some boilers are capable of working on two types of energy source at once. Such units are usually called universal or combined. Their main advantage is the ability to choose the type of fuel at the user's discretion.

The versatility of heating equipment is manifested in its design, which affects the cost. But all the costs of the purchase quickly pay off with those advantages that the user will find it difficult to refuse over time.

Features of single and double-circuit boilers

When choosing the type of boiler equipment, due attention is paid to its characteristics regarding performance and efficiency. It is possible to increase them by increasing the number of contours in the structure. Single-circuit models are intended either only for hot water supply, or exclusively for heating living quarters in an apartment.

Both functions can be combined by installing two single-circuit boilers or installing an additional boiler, but this approach is associated with a significant increase in costs.

It is easier to install one double-circuit unit, the cost of which is only slightly higher than the price of devices with one circuit. Its feature is the possibility of simultaneous use as a heating device and a water heating device (boiler).

Place selection

Most of the images of heating boilers are produced in a floor version, which requires a separate room for its placement - a boiler room. Equipment manufacturers take this into account and, when designing, provide for the installation of reliable cast-iron heat exchangers in the unit.

Unlike floor-standing models, their wall-mounted counterparts are characterized by compact dimensions and relatively low weight. However, these types of equipment are limited in power, which is especially noticeable in dual-circuit systems.

Regardless of the size of the home, many users prefer floor-standing models equipped with a cast-iron heat exchanger. This is due to the fact that they are less demanding on the quality of power supply.

The subtleties of using boilers

For normal operation, most of the models considered require electricity. An exception to the rule is solid fuel heating units that burn coal or firewood in their firebox.However, electricity is still needed to trigger the automation and the full functioning of the pumps that make up the structure. A good solution in this case is the purchase of an electric generator. This decision is especially important for those Russian regions where power outages are very frequent. In addition, before buying a boiler suitable for the stated purposes, users in most cases are concerned about the safety of its operation.

The presence of such protective functions is desirable:

- flame sensor;

- thrust sensor;

- blocker of work with a decrease in pressure in the gas pipeline and a decrease in the fuel supply;

- overheating protection system.

All the listed methods and means of protection are the minimum that will allow you to protect expensive equipment from accidental breakdowns, and the housing itself from the threat of fire and fire.