When insulating building structures, mineral wool or bulk compounds are traditionally used - most often from expanded clay. They attract the attention of professional builders for their relatively low price and good thermal insulation performance. However, they are being replaced by vermiculite boards, made on the basis of natural components and not containing harmful substances in their composition. In terms of its technical performance, this insulation is comparable to the parameters of mineral wool, but surpasses it in terms of durability and soundproofing properties.

Insulation type

Insulating material vermiculite is made on the basis of volcanic rocks, which include several chemical elements and natural impurities. Due to this composition, it has a special bronze or golden hue. In construction, expanded or foamed vermiculite materials are mainly used, obtained by heat treatment of the original mineral at temperatures of the order of 900-1200 °.

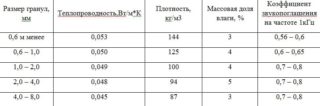

Intense heat exposure causes a significant increase in the initial volume - it increases by about 20-25 times. As a result of heat treatment, the vermiculite insulation acquires the properties of a material characterized by low thermal conductivity and increased density. The thermal conductivity of vermiculite material takes values of 0.04-0.12 W / m * K.

Material features and characteristics

The characteristics of vermiculite boards are represented by the following operating parameters:

- thermal conductivity;

- strength indicators;

- soundproofing properties;

- fire resistance and thermal stability;

- hygroscopicity.

A feature of thermal insulation materials based on vermiculite is considered to be a high rate of thermal conductivity, obtained due to the layered structure. There are voids between the thin plates in the slab mass, into which air can easily penetrate. This does not weaken the bonds between the structural elements of the material, due to which it has sufficient strength. In terms of thermal conductivity, a vermiculite slab is not inferior to workpieces made of mineral wool, and in terms of deformation stability it surpasses them.

Another feature of the insulation is good hygroscopicity - the ability to absorb moisture. But thanks to the layered structure, it also easily gives it away - it protects the elements of building structures from rotting and destruction. Good sound absorption is achieved due to the elasticity of the material and other characteristics. The maximum sound absorption is achieved by compressing the slab until its volume is reduced by 20%.

The thermal insulation material melts when the temperature reaches 1300 °, and does not form any harmful emissions during a fire.

Slab sizes

Vermiculite is produced in the form of discrete fractions, the size of which does not exceed 4 mm (in the form of backfill). On their basis, building boards of the PVO-500 type are made with a thickness of about 20-60 mm and dimensions of 600x600 mm (1200x600 mm).The assortment of this material includes the following five standard sizes of vermiculite products: 1200x600x20 mm, 900x600x20 mm, 600x600x20 mm, 600x300x20 mm and another atypical size 300x300x20 mm.

Advantages and disadvantages

It is more convenient to consider the advantages of vermiculite in comparison with mineral wool, which is a benchmark for assessing the quality of insulation material. In relation to it, vermiculite-based slabs are more durable, which is explained by their high strength. According to this indicator, it is superior to expanded clay and perlite.

The advantages of insulation also include the following properties:

- vermiculite blanks are not inferior to mineral wool in terms of basic indicators;

- slabs do not retain moisture, without forming condensation inside building structures if there are conditions for steam removal;

- with a sheet thickness of 15 mm, the slabs are resistant to an open flame for 45 minutes.

The latter circumstance makes it possible to use vermiculite for decorating fireplaces installed in private houses.

In terms of their ability to absorb noise, such plates are superior to all previously listed heaters. In addition, the thermal insulation material made from rocks is environmentally friendly and does not emit substances harmful to human health. For the same reason, it is cheaper than other insulation materials, including mineral wool.

The disadvantages of this type of heat insulators include:

- due to the high hygroscopicity of the material, when installing insulation boards, it will be necessary to ensure good ventilation of the premises;

- during their production, incomplete removal of asbestos particles, harmful to humans, is possible;

- when purchasing the material, you should make sure that you have a quality certificate confirming its safety.

Considering all the problem areas of vermiculite products, its use is considered fully justified.

Areas of use

Vermiculite slabs are sometimes used to insulate walls, floors and roofs of buildings under construction. High fire resistance and the ability to maintain their shape make it possible to use them in the following areas:

- for insulation of attic rooms;

- for insulation of pipes of household stoves and fireplaces;

- in order to protect walls located next to chimneys;

- as a packaging material used in the transportation of fragile and valuable goods;

- in metallurgy - to reduce heat losses during steel pouring;

- as a heat-resistant steam insulation for industrial gas ducts, boilers and thermal furnaces.

Often this material is used as a component of the pie, which is arranged when decorating fireplace structures.

Terms of use

When applying this material, you will need to follow certain rules:

- on top of the insulation layer, a diffuse membrane must be installed, which performs the function of waterproofing;

- attics insulated with vermiculite must be ventilated by artificially organizing the pressure drop;

- when insulating frame structures or structures of the "well masonry" type, vermiculite slabs are placed in the voids between bricks or structural elements;

- the products are placed in the cavities gradually as the structure is being assembled.

The current building codes prescribe that the slabs be fastened in any way available for this. However, free stacking of workpieces is not excluded if they are placed in cavities without gaps.

Vermiculite combinations

Despite the quite affordable price and undeniable advantages, when used without additives, vermiculite slabs are quite expensive during construction. For this reason, they are used in combination with other insulation materials.To reduce production costs, vermiculite is often mixed with sawdust. In such a combination, the finished product retains its original characteristics and does not condense over time due to its own weight.

By mixing the components of finishing materials with vermiculite granules, a composition called "warm plaster" is obtained. This combination has undeniable advantages when compared with the usual methods of wall surface finishing. This is manifested in the fact that the specific gravity of plaster with vermiculite is slightly lower than that of other similar compositions.

In terms of the main thermal indicators and other defining parameters, the considered combination also surpasses them.

A 25 mm plaster and vermiculite cake achieves the same thermal insulation performance as a 100-150 mm layer of a mixture of cement and sand. The plaster mixture prepared in this form can be easily applied to almost any surface to be finished, including brickwork and concrete slabs.

Manufacturers

Among the well-known manufacturers of materials and boards based on vermiculite, the following domestic firms and companies stand out:

- LLC PKO Dmitrovskaya Thermal insulation (city of Dmitrov). The main activity is the production of stitched and shaped products from vermiculite.

- SFR group of companies (Kolpino city). The main activity is the production and sale on a wholesale scale of a wide range of various insulation materials.

- Specialists from the Leningrad region produce dry building mixtures, expanded vermiculite, as well as a number of samples of materials for electrical purposes.

- Trading house Vermit from Chelyabinsk is engaged in the production and sale of fire retardants and plates using vermiculite.

To this list can be added NGO Organika from Chelyabinsk and several other small companies that do not deserve special attention.