A gas heating boiler is a device for heating a room that uses natural gas as a fuel. With the help of the burner, the fuel is converted into heat energy and transferred to the heat carrier - most often water. The heated liquid spreads through the pipes into the radiators and thus heats the apartment, private house, utility rooms.

Gas boilers device

The design of a conventional gas boiler includes the following elements:

- Gas burner with nozzles through which gas is supplied for combustion. Thanks to the nozzles, the fuel is evenly distributed and consumed more economically.

- The heat exchanger is a metal box, inside which pipes with a circulating heat carrier pass. The incoming cooled liquid from the radiators heats up again and moves back. Depending on the design, there can be one or two heat exchangers. In simple boilers, the heating is temporarily turned off during water heating.

- Circulation pump. Serves for forced transportation of liquid through pipes.

- An expansion tank is needed to temporarily bleed off liquid that expands when heated.

- Mechanisms for the removal of gas combustion products. In atmospheric boilers, the device is connected to the chimney. In turbo boilers, combustion products are removed by a fan through a pipe.

- Electronic board - boiler control unit. Monitors the specified settings of the equipment using the data of the built-in sensors.

- Pressure gauge for monitoring the pressure in the system.

- A display that shows the performance of the equipment.

Depending on the design, each element can have various modifications that affect the cost and service life of the product. For example, a cast-iron heat exchanger is considered the most reliable, and a copper layer is applied to a steel one to extend the service life.

Gas boiler with different connection outlet

The purpose of installing single-circuit and double-circuit gas boilers is different. If the house or apartment already has one heating element that heats water, the boiler can only be used for heating purposes. If there are no such devices, you need to choose a double-circuit equipment that can switch from the heating function to heating water for domestic needs.

Single-circuit

The disadvantage of a single-circuit boiler is the need to purchase another expensive device - a water boiler. The cost of two units is more expensive than one double-circuit boiler. If the capacity of one device is not enough, for example, if there is an extension, the boiler / boiler option is justified.

Double-circuit

Double-circuit equipment is capable of performing the functions of a boiler and a heating boiler at the same time. Moreover, the design of the boilers is more complex. Differences can be:

- In the heat exchanger circuit - bithermal or double separate. In the first case, water for hot water flows along one route, and for heating - along another. With a double heat exchanger, each device controls its own volume of liquid.

- In the presence or absence of a built-in boiler with a volume of up to 60 liters.

When buying a gas boiler, you need to know that some of them can only heat water during the heating season, when the burner is constantly on. In summer, the unit does not supply hot water. Such models are cheaper and are designed for the fact that the house already has a boiler.

Double-circuit boilers are distinguished by the presence of a three-way valve, which changes the direction of the liquid either for heating or for heating for domestic needs.

Design features

Depending on the installation method, models of gas boilers are floor-standing and wall-mounted. Some are suitable for private houses, it is advisable to place them in a specially equipped boiler room, where there is enough space. Others are designed for use in an apartment and are mounted on the walls.

Floor standing

The power of the floor units is from 10 to 100 kW. Weight of devices up to 100 kg. Most often they have cast iron parts inside. Floor standing models are considered more reliable as they are less dependent on electronics. There are single-circuit and double-circuit.

Wall mounted

Wall mounted equipment is lighter and more compact than floor standing equipment. To safely stay on the wall, the weight of the product should not exceed 50 kg. They are produced for apartments, therefore, they are more often produced in two-circuit. They take up less space, as additional elements are already built into the boiler.

The advantage of wall-mounted models is simpler installation. A chimney is not needed for them - it is enough to install the boiler on the wall that faces the street, punch a hole and bring out the pipe.

The disadvantage of wall-mounted models is the lower power compared to floor-standing units. Usually, for an apartment or small house, there is enough power in excess. 1 kW is capable of heating 10 square meters of premises.

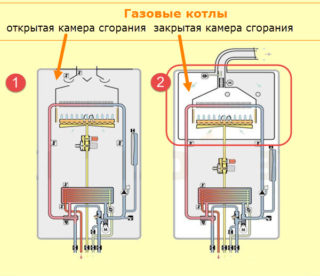

The combustion chamber

When buying a gas boiler for heating a private house or apartment, the capacity, installation method and the number of circuits are assessed. But there is another important parameter - the combustion chamber. It can be open or closed.

Open

When the combustion chamber is open, air enters the burner from the room. Benefits:

- no air duct needed;

- installation of such equipment is easier;

- relative non-volatility - if the unit does not have a complex electronic control system, the voltage does not particularly affect the efficiency of work;

- lower cost compared to boilers with a closed combustion chamber.

Negative sides of an open chamber:

- the need for constant ventilation of the room from which the device takes oxygen;

- the operation of the boiler affects the humidity - the air in the room is drier;

- do-it-yourself installation of a chimney carries a fraction of the risk, since with poor sealing, carbon monoxide will begin to flow into the room.

You will have to clean the internal parts more often, since the unit with an open combustion chamber sucks in dust along with air.

Closed

The principle of air circulation in boilers with a closed combustion chamber is different. Air is pumped from the street using a built-in fan. During combustion, residual products are also escaped thanks to the forced draft.

The advantage of a closed combustion chamber:

- No mounting restrictions.

- Can be safely placed in the kitchen.

- The presence of filters for outdoor air, so that the internal parts are not clogged.

Lack of this type of design:

- The need to equip two channels - for air supply and removal of combustion products.

- The fan stops if the power goes out. Smoke extraction is not possible without a fan.

- Boilers with a closed chamber are much more expensive.

Usually a coaxial chimney is connected to gas boilers of this type. Its essence is in the installation of two pipes located one in the other - air is taken in through the inner, combustion products are discharged through the outer.With the help of a coaxial-type chimney, it is possible to achieve gas savings due to heating the air masses with the outgoing smoke.

The location of the coaxial pipes eliminates the leakage of carbon monoxide, therefore, the boiler works safer. The chimney can be done by hand according to the manufacturer's instructions.

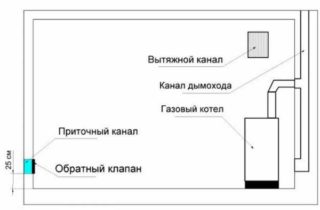

Boiler exhaust system design

The exhaust system device in a private house can be divided into 3 types:

- By the method of air supply - with forced or natural circulation. In the first case, a fan is installed, in the second, air masses enter through the windows and doors.

- For the intended purpose - exhaust, mixed type and supply. The exhaust system gives the spent air masses to the ventilation shaft. The supply system removes gases by pushing them out with a stream of clean air sucked into the room by a fan. The mixed-type design has elements of the exhaust and supply systems - a supply fan and a ventilation shaft for removing exhaust gases.

- By design. It is a ducted and non-ducted ventilation system.

The choice of an exhaust system for a gas boiler depends on the presence of a chimney or ventilation. In old houses, all work has to be done at the stage of equipment installation. If metal-plastic windows are installed or planned in the house, there is no need to count on natural circulation, since the tightness of plastic windows does not imply fresh air entering through the windows. In the summertime, natural circulation of air masses is impossible, since the principle of its operation is based on the difference in temperature inside and outside. The best option is a supply or mixed exhaust system. A mixed system with a ventilation shaft and a suction fan works best.

Volatility of gas boilers

Volatile gas boilers make up the majority of models produced for equipment consumers. Among them are floor and wall. Volatile boilers consume less fuel, as they have built-in temperature sensors, reducing the amount of gas consumed. The energy is consumed by the electronic board and the circulation pump.

The downside is the additional costs and the presence of a board, which in case of failure is expensive to repair. To avoid voltage surges, it is recommended to install a stabilizer - for some manufacturers this point is decisive for the provision of warranty repairs.

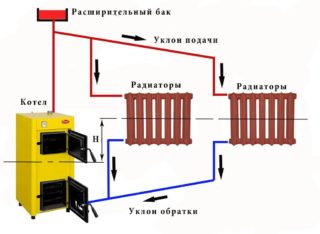

Autonomous systems

Most models of the floor type are produced non-volatile. An important condition for the installation of such equipment is its location at the lowest point of the room - usually the basement or basement. Water circulation occurs when it is heated.

A distinctive feature is an open combustion chamber - this helps to increase traction for the removal of toxic waste from the combustion process. There is a backdraft sensor to turn off the equipment if the exhaust system is not working properly. There are two burners in non-volatile boilers - for the fuse and the main one.

All the disadvantages of an autonomous system are manifested with improper design, therefore, installation should be entrusted to professional gas workers, who, in addition, have equipment for measuring the level of carbon monoxide of operating equipment. Carbon monoxide is odorless, therefore doubly dangerous.

Selection criteria for a private house

The choice of a gas boiler comes from several calculations:

- How many people live in the house. This will determine how much water needs to be heated per day to serve all residents, if a double-circuit boiler is planned. To provide one person with water, a model with a built-in boiler is suitable.

- The area of the heated room. On average, for heating 10 sq. m requires 1 kW of energy.This indicator increases significantly if the ceiling, walls, floor are not insulated in the house, old wooden windows are installed - most of the heat will go up and dissolve in the cold masses located above the ceiling.

- The non-volatile model is chosen if it is possible to mount the boiler at a low point, for example, in an equipped basement. Such equipment is not suitable for apartment heating. Its operation is associated with increased risks.

- Often apartment models are chosen for a private house, which does not affect the quality of heating in any way.

The difference between boilers for a private house and an apartment is insignificant, so wall models can be successfully installed in houses and cottages.

The most well-proven devices of European manufacturers - Bosch, Grandini, Vilent, Wiesmann, Baksi, Proterm. Companies produce a large assortment designed for different areas of the premises, as well as different operating conditions - with or without a stationary chimney.

Before turning on the boiler, it is recommended to familiarize yourself with the operating conditions of the equipment indicated in the instructions. This will prevent breakdowns and costly repairs. You should also study the terms of warranty service so that there are no mutual claims with representatives of the service center that serves the boilers.