A professionally planned heating system is a complex complex for creating a comfortable temperature regime in a residential building, commercial and industrial building. In addition to the mandatory elements of the boiler, radiators and pipes, it must include control components. They are collectively called valves for heating systems: shut-off, control. Without it, the work of an autonomous complex would be impossible.

Requirements for the material of manufacture of valves

At the first stage of acquaintance, it is necessary to find out which fittings for heating systems perform certain functions. Its general purpose is to regulate the coolant flows, distribute along the contours of the system, and decrease or increase the volume.

Depending on the design, heating fittings are divided into two types - shut-off and control. Each of them has a certain functional load that directly affects the operation of the entire system.

Shut-off valves

Designed for forced reduction or final shutdown of the coolant in a certain section of the pipeline or radiator. Traditionally, cranes or gate valves with various types of designs are used for this. When choosing a particular model, first of all, it is necessary to pay attention not only to the geometric parameters of the connection, but also to the material of manufacture. A well-made shut-off valve for heating must withstand the critical operating temperature and maximum pressure. These parameters should be indicated in the passport or directly on the product body.

Control valves

It is necessary to ensure the safety of the system. First of all, control valves for heating stabilize the pressure inside the pipes, and also regulate the degree of water heating by mixing cold and hot streams. In addition to the above requirements for heating shut-off valves, you can add a degree of actuation regulation or mixing of flows, as well as the possibility of automatic operation. That is why some models are equipped with electronic controls.

As for the material of manufacture, brass, bronze or ductile iron are most often used. Steel radiator fittings are rarely different, since the properties of this material are not well adapted to operating conditions in a hot water system.

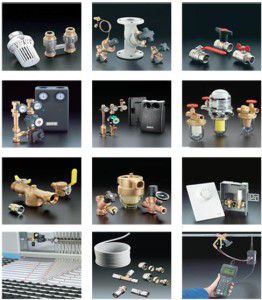

On sale you can find combined units of fittings for heating, in which 2 or more elements are installed. Installation of such models is much easier than each type of fittings separately.

Shut-off valves for heating

Heating fittings for regulating the volume of fluid flow in pipes are one of the main elements of any heating system. It is installed at those points of the line where it is necessary to partially or completely restrict the flow of water.

Almost every manufacturer provides a catalog of fittings for heating. It is necessary for the correct choice of a particular model. The main parameters are.

- The diameter of the inlet and outlet pipes. Required for connection to the trunk.It is important that in a fully open state the valve or valve does not limit the speed of movement and the volume of the coolant;

- The degree of regulation. The accuracy of reducing or increasing water pressure depends on this. Ball valves are used to quickly shut off the flow, and with the help of wedge valves, you can smoothly regulate the flow of the coolant in the pipes;

- Possibility of installing an automatic regulator of the degree of opening for heating valves

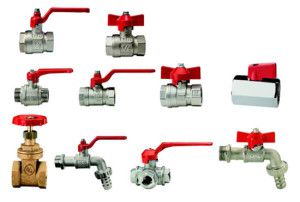

Often, taps and valves are used to complete the heating system. In addition to the correct installation and selection of a specific model in terms of performance, it is necessary to know the device of these elements of the heating system.

Heating taps

The use of taps as fittings for heating radiators or for creating pipeline shut-off points is due to their relatively simple design and the ability to choose from several model options. Depending on the method of regulating the flow of water, the following types of taps are distinguished.

- Ball... A ball with a through hole is located inside the structure. As the handle is turned, the bore increases or decreases. This shut-off valve for heating radiators is characterized by the ability to quickly shut off - for this, it is enough to turn the lever 90 degrees. However, with the help of such a crane, it is difficult to perform smooth adjustment;

- Rod... A rod with a rubber or ceramic gasket is used as a locking mechanism. To close and open completely, you need to make several full turns of the handle. Such shut-off valves for heating are used to accurately control the volume of the heat carrier flow.

Installation and selection of valves should be carried out only in agreement with the operating parameters of the system.

Care should be taken to select the gaskets for installation. In systems with antifreeze, it is recommended to install paronite, as they are least susceptible to deformation.

Heating valves

Structurally, they are similar to the above-described rod valves. The main difference is that their size is much larger. The shape of the internal channels has also been changed - the wave structure provides protection against significant pressure drops. This ensures stem integrity and complete sealing of heating valves when closed. Such mechanisms are installed in central heating pipelines, where the pipe diameter exceeds 100 mm.

Heating control valves

It is designed to test the operation of the heating system as a whole or in a specific area. It depends on the design and operating parameters. Consider the most popular and mandatory models for installation.

Mayevsky crane

If the heating of a particular radiator has significantly deteriorated, there is a high probability of an air lock. To prevent overheating of the coolant, it is necessary to install Mayevsky taps on each of the heating devices in advance.

This heating control valve is a needle valve that is completely sealed when closed. Installed on the upper radiator pipe, in the event of air congestion, it helps to eliminate them. To do this, use a key or a screwdriver to loosen the degree of pressing the curtain. This is done until the characteristic sound of the outgoing air is heard. The procedure ends only when the coolant begins to flow.

Heating radiators are often equipped with shut-off valves. This point must be clarified at the stage of acquisition.

Check valve

It is necessary to prevent the reverse movement of water in the pipes. It can be found in heating fittings catalogs for both small private systems and district heating.

The principle of operation of this device is based on the fact that the pressure of the water pressure acts on the valve seat, pushing it back. As a result, the liquid circulates in the pipes. If, for some reason, the water starts flowing back, the valve returns to the closed state. This mechanism is necessary in systems with complex line routing. In particular, it is installed as a shut-off valve for heating radiators. This increases the safety of work and increases the efficiency of the entire system.

It is recommended to install check valve fittings for heating systems with the ability to adjust the indicator of its opening pressure.

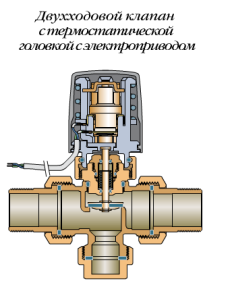

Mixing units

For the installation of a water underfloor heating, it is necessary to provide a mixing of hot and cold water. This is due to the different temperature regimes in the heating pipes and underfloor heating. 2 or 3 way mixing units are used as the main mechanism.

Structurally, they are similar to needle cranes. But in addition to the inlet and outlet nozzles, they have additional connection points. Two-way models provide mixing of a coolant flow with different temperatures by opening the stem to a certain height. In three-way designs, dampers are installed. Changing their location reduces or increases the flow of water.

Such control valves for heating can be controlled manually or automatically. For the latter, an electric drive is mounted connected to a temperature sensor in pipes or indoors. Depending on the set heating level, the position of the stem or damper is regulated.

Safety valve

If the level of water heating in the pipes exceeds the set parameter, a sharp jump in pressure occurs. To prevent a breakthrough, another type of shut-off valves for heating are installed, the regulatory functions of which are aimed at discharging excess water or air from the system.

The most popular of these is the safety valve. Unlike the Mayevsky crane, it is designed for higher pressure indicators. In the event of an emergency, the water pressure acts on the seat, as a result of which the stem rises. Excess coolant or air leaves the system, and the valve remains open until the pressure stabilizes. This shut-off valve for heating must be installed correctly. Experts recommend installation on a return pipe before entering the boiler and before the circular pump.

Additional devices for heating

These primarily include thermometers and manometers. They are necessary to monitor the status of hot water. By default, such devices are installed in the heating boiler. But besides this, their installation is necessary in critical areas of the system. This applies to control valves for underfloor heating (manifold assembly). A pressure gauge must be present in the safety group together with an air vent.

For each valve for heating systems, shut-off or control, the main performance indicators are often indicated on the body - the maximum (minimum) level of pressure and temperature. How can you choose the optimal model even without a passport for it?

As an example, you can see the range of valves from Valtec: