The complete set of any heating system must include adjustment and safety elements. With their help, the heat supply parameters change - work stabilization, automatic adjustment. For these purposes, valves for heating systems are used: balancing, reverse, three-way.

Appointment of valves for heating

Autonomous or district heating must be adapted to the current values of the parameters - pressure and temperature in the system. To accomplish this task, a bypass valve in the heating system, a mixing valve, a safety valve, and others is required.

Unlike shut-off valves, they work in automatic or semi-automatic mode. All heating control valves must correspond to the parameters of the specific heat supply.

To do this, you must first calculate the characteristics, draw up a detailed diagram and, according to the data obtained, select the optimal heating drain valve and other types of similar elements.

The main criteria are:

- System operating temperature... The shut-off valve for heating must function normally even with critical thermal effects;

- Pressure - nominal and maximum. Each pressure reducing valve of the heating system has certain operating limits, which should be lower than the maximum by 5-10%;

- Coolant type - water or antifreeze... In the latter case, malfunctions are possible, since the air valve for heating is not designed for a liquid with a higher density than water.

A suitable valve for bleeding air from the heating system is selected at the design stage. The operation of this device and similar components should stabilize the state of the system in the event of a risk of emergency situations. Therefore, it is necessary to know the principle of operation and types of valves for heat supply.

Some performance characteristics are indicated directly on the heating bypass valve body. If this is not the case, professional advice is imperative.

Heating bypass valves

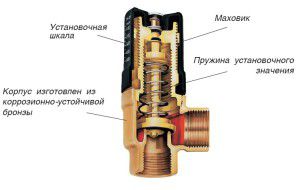

Often, during the operation of the heat supply, the temperature regime is exceeded. This provokes an increase in pressure and, as a result, the destruction of system components. For the timely removal of part of the coolant, a bypass valve for heating is required.

The principle of operation of this component is simple - the heat carrier pressure is constantly acting on the bypass valve seat in the heating system. When the spring force is less than the external pressure, the stem is displaced and some part of the hot water is removed. Once the pressure has stabilized, the seat returns to its original position.

There are two types of heating control valves - with a constant response pressure and the ability to manually set this parameter. For autonomous heat supply systems, the installation of the second type is recommended, since they can be adapted to any parameters.

The heating pressure valve has the following functions:

- Reduces hydraulic load on the circulation pump;

- Prevents rust... When the temperature is exceeded, oxygen is evolved. It is the main cause of oxidation of metal components in heating;

- Reduces the noise level of heat supply... Without a pressure valve for heating, water circulation may increase and, as a result, vibration and noise will increase.

This item is installed for closed systems only. In gravitational heating, a pressure valve is not needed for heating supply. If the temperature regime is exceeded, the expansion of the coolant is compensated for by means of an open expansion tank.

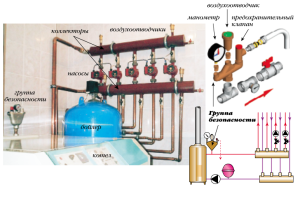

The bypass valve in the heating system is included in the mandatory configuration of the safety group. It is also installed at the highest point of the circuit and in critical areas.

Types of control valves for heating

Normal heat supply operation is impossible without a minimum set of control valves. They are designed to stabilize heating parameters and change their values depending on the set settings.

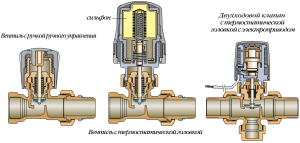

The principle of operation of the pressure reducing valves of the heating system is based on limiting the flow of the coolant by changing the section of the pipeline. For this, the design has an adjusting head and shut-off valves. Bypass valves for heat supply are divided into the following types:

- With manual flow control;

- With mechanical thermal head. When the thermal element is exposed to temperature, it expands and pressure on the valve seat. As a result of this, the rod is lowered, limiting the flow of the coolant;

- Servo driven. To operate this type of heat supply control valve, the control element is connected to a control unit (programmer) or a temperature sensor. When a control command is received with the help of a servo mechanism, the position of the stem changes and, as a result, the volume of the coolant inflow is regulated.

These types of pressure reducing valves for heat supply systems allow you to change the main parameter - the temperature mode of operation. The installation of regulators is carried out in the piping of radiators, batteries, in the collector nodes of the warm floor.

The installation of the control valve must be carried out in such a way that the outgoing heat from the batteries does not affect the thermocouple.

The purpose of the balancing valve in heating

Another type of control valve is a balancing valve in the heating system. Structurally, it is similar to the adjusting one, but has a number of features of operation and installation.

The purpose of the balancing valve for heating is to regulate the volume of the coolant depending on the value of its temperature. Their installation is optional for systems with short or no heat distribution problems. They are installed on each heating circuit.

After installing a shut-off valve for heating, the following heat supply indicators will improve:

- Even heat distribution on all heating circuits;

- Providing hydraulic stabilization of the system, lack of a sharp drop in pressure;

- Reduced heating costs - fuel consumption is optimized, the thermal mode of operation is stabilized;

- After installing a balancing valve in the heating system, it becomes possible to partially or completely disconnect individual circuits from the general heat supply.

To control the current readings of the temperature pressure, the valve design provides fittings for installation with a thermometer or manometers. Depending on the design, the regulation of the coolant flows is carried out in manual or automatic mode.

Balancing valves are installed in collector systems of private houses or in two-pipe heating of an apartment building.

Safety heating valves

In addition to the heating bypass valve, for the normal operation of the system, the installation of other types of control and protective valves is required. During the operation of the heat supply, excess air may appear, the reverse movement of the coolant will occur. To prevent these phenomena, it is necessary to foresee the installation of an air valve for heating and return.

Depending on the functional purpose, there are two types of safety valves - to remove air from the system and to prevent back movement of water in the pipes. Without these elements, the operation of the system can be unstable, which will lead to a violation of the temperature regime, destabilization of pressure and the creation of emergency situations.

Installation of safety valves is carried out in the following areas of the system:

- In places with the highest probability of overpressure - after boilers, circulation pumps, on collectors;

- On the return pipe, a heating ball valve or its petal analogue is necessarily mounted. It is also necessary to install this component in the piping of the circulation pump;

- At the highest point in the circuit - to remove air from the system. A Mayevsky crane is installed on radiators and batteries.

Safety valves should not impair the performance of the heating system. First of all, they eliminate possible malfunctions in the operation of heat supply. In the "inactive" state, these components of the system should not worsen the speed of movement of the coolant, affect the temperature regime.

To prevent a sharp pressure drop in the make-up unit, a heating drain valve must be installed. It will prevent a sudden surge in pressure.

Heating air valve

During the operation of the heating supply, air locks may form in pipes and radiators. The reason for this is the high oxygen content in the water, the temperature of the coolant is over + 100 ° C. As a result, oxidation of metal components occurs, and the temperature distribution changes. To avoid these situations, it is necessary to install valves to bleed air from the heating system.

First of all, the air valve for heat supply is mounted in the safety group together with a drain and a pressure gauge. In the heating circuit, they are located on a straight line leading from the boiler. In this place, the highest temperature of the coolant, as well as the maximum pressure indicators. In the collector circuit, it is mandatory to install heat supply drain valves on each manifold.

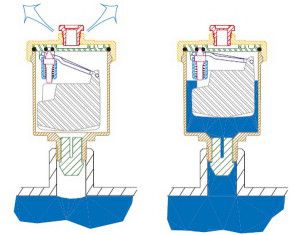

Air vents are divided into two types, each of which is intended for installation in certain areas of the system:

- Mayevsky crane... Installed in a radiator (battery) and is needed to remove air locks;

- Automatic air vent... It is mounted at the highest point in the system, as well as in security groups. Air comes out through it from the heating system.

For the latter model, it is important to comply with the operating conditions. After a long period of inactivity, there is a high probability that some moving components will "stick" and then the air vent will not work. To avoid this, you should regularly inspect the structure and, if necessary, replace it with a new one.

Most models of the heating system bleed valve are designed for pressures from 0.5 to 7 bar.

Heating check valve

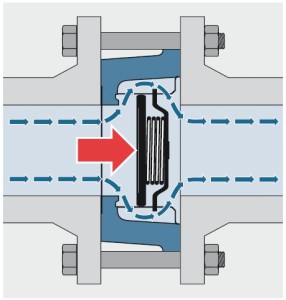

In gravitational systems and in heating circuits without a circulation pump, there is always the possibility of a change in the direction of water movement. In this case, the boiler heat exchanger could be damaged due to overheating, as well as failure of other components. To prevent such situations, a check valve is installed.

In large heating schemes, a heat supply ball valve is installed.Under the action of the reverse flow of water, the polymer ball closes the pipeline, thereby preventing the movement of the coolant. As soon as the direction changes, it goes down under the influence of gravity. The solenoid valve for the heating system works on the same principle. The difference lies in the control element - a solenoid or an electromagnetic coil is used for this.

The advantages of installing a solenoid valve in a heating system are as follows:

- Possibility to connect to the programmer;

- Setting the operation mode of the device depending on external factors - temperature or pressure;

- Reliability of work.

The disadvantage of solenoid valves in heat supply is their dependence on the supply of electricity. In autonomous heating, a spring-loaded version of a check valve is used. The pressure of water constantly acts on the seat, compressing the spring. As soon as the direction changes, there will be an automatic overlap of the coolant movement.

In systems with forced circulation, the check valve is mounted on the bypass pipe of the pumping unit to prevent changes in the fluid flow in the line.

Three-way heating valve

To regulate the water temperature in the two-pipe and collector systems, a three-way mixing valve is installed in the heating system. It connects to the supply and return pipes.

The principle of operation of a three-way mixing valve in a heating system is to mix hot and cold water in the pipes. This allows you to set the required heating agent heating level without changing the boiler operating mode.

The determining factor in choosing a three-way valve model is a control element, which can be of the following types:

- Hydraulic;

- Pneumatic;

- Electric.

In autonomous heating, models with an electric drive are most often installed. They can be connected to the control elements of the system. It is important to set the mixing mode correctly so as not to impair the heat supply parameters.

The selection and installation of heating valves should only be carried out after an accurate calculation of the system. As a result of this work, the parameters of all components are determined, and based on this data, a selection is made from the existing models.

For a better understanding of the functional features of the three-way valve, it is recommended to familiarize yourself with the video material: