How can the pressure in the heating system be effectively stabilized? The solution to this problem lies in the application of complex measures, including the installation of special components. One of them is the expansion tank for the heating system: closed, open, the pressure in which must be stable under all operating modes.

Purpose of expansion heating tanks

Before considering expansion tanks for the heating system, you need to find out their purpose. It is associated with the property of water or a similar heat carrier to expand under the influence of temperature. As a result, the pressure in the system rises. Its excess must be compensated.

The use of an air vent or a similar shut-off valve is effective, but it has certain disadvantages. The main one is the exit of water from the system, as a result of which there is a high probability of the formation of air locks. But how does the expansion tank work in the heating system when overpressure occurs? Let's consider the general principle of operation using the example of the simplest open model:

- In normal condition, the closed expansion tank is 2/3 full;

- With an increase in the volume of the coolant, the filling level of the container increases, thereby stabilizing the system;

- As soon as the water temperature drops to the optimal level, its volume in the system will decrease to normal;

- At the same time, the level of the coolant in the tank stabilizes.

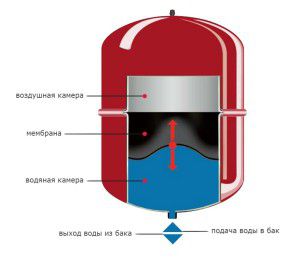

Closed models work the same way. The difference lies in the design - it is divided into 2 chambers. The first is connected to the heating main and is filled with water, and the second creates a pressure equal to the normal for this system. Moreover, both chambers are separated by an elastic membrane. As soon as the volume of the coolant in the pipes exceeds the critical one, the pressure in the expansion tank of the heating compensates for this process by displacing the membrane. In this way, the actual heating volume is temporarily increased.

For a system with forced circulation, it is forbidden to install an open expansion vessel. He will not be able to provide the required tightness.

Expansion tank, open type

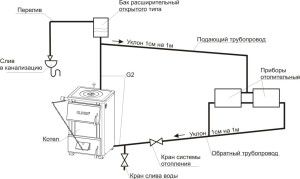

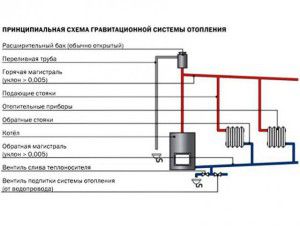

The simplest varieties are open models. In most cases, they are a leaky container installed at the highest point of the system. This is an important point, since the location of the expansion tank in the heating system directly affects the functional and performance characteristics.

The basic principle of operation of an expansion tank in a gravitational heating system is to compensate for the thermal expansion of the coolant. You can make this element yourself, or purchase a factory model. The important operating parameters for an open tank are:

- Resistance of the material of manufacture to constant exposure to water and sudden temperature changes. Products from stainless steel have proven themselves best;

- Correctly calculated volume, directly dependent on the amount of water in the system;

- The impossibility of changing the location.This is due to the design.

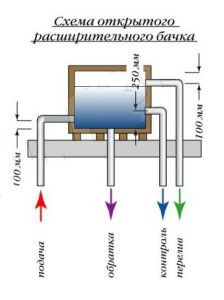

Before installing an expansion tank in an open heating system, you need to familiarize yourself with its advantages. The main one is the affordable cost and easy installation. In addition to the traditional scheme, you can make a small upgrade. For this, in addition to the connection pipes to the main, additional ones are mounted - controlling the minimum liquid level and connected to the make-up pipe to replenish the system.

One of the disadvantages of this design is the constant evaporation of the coolant from the system. At first glance, this indicator is insignificant, but if the installation of a heating expansion tank was performed in an unheated attic, the difference in temperature between the air and the coolant will adversely affect the efficiency of the system.

The way out of this situation is to insulate the walls of the container and install the top cover with a snug fit. In this case, the rate of evaporation of water will significantly decrease, and external factors will not affect the temperature regime of operation.

In order to make an expansion tank for heating with your own hands, you can pick up the appropriate container and install connecting pipes in it.

It is not recommended to install plastic containers, since in most cases they are not designed for high temperature exposure. The best option is a sealed galvanized metal structure.

Closed expansion tank

It is much more difficult to choose a closed-type expansion tank. This is due to the increased requirements for the design, since it is designed for operation in systems with increased pressure levels.

The role of the expansion tank in the heating system is more significant than for open models. During the operation of the circulation pump, in combination with temperature fluctuations, pressure surges occur. By changing its location, the elastic membrane of expansion tanks for the heating system stabilizes the pressure to the desired level.

It is important to consider the following design and operation features:

- Correctly dimensioned closed expansion tank volume. To do this, you must use the recommended technique;

- Membrane type - balloon or diaphragm;

- Possibility of installing a pressure gauge together with a pressure relief valve in the air chamber. This is necessary for a sharp decrease in pressure in the heating system.

But how will the expansion tank work in the heating system if its parameters do not meet the requirements? In this case, he simply will not perform his functions.

Replacing the membrane

When choosing, you need to pay attention to the design features of a particular model. Since it is difficult to make an expansion tank for heating with your own hands, it is best to purchase a ready-made factory one. An important point is the possibility of installing a new membrane. Periodic exposure to pressure in the heating expansion tank over time can render it unusable - elasticity or tightness will be lost.

In this case, the membrane must be replaced. It is best to initially purchase a flange mount design. Their body is not monolithic, but consists of 2 parts, connected by a flange. Dismantling this element, you can replace the defective membrane with a new one. Having learned the basic principles of the expansion tank in the heating system, you need to adhere to the following work order:

- On the connecting pipe of the tank with the heating system, shut-off valves must be installed. The access of the coolant to the water chamber is blocked;

- During dismantling, the coolant will flow from the water chamber - you need to prepare a container in advance to collect it;

- The air chamber pressure relief valve is activated.

Further actions depend on the model of the expansion tank.

Even in a small heating system, the role of the expansion tank is important. For a stand-alone circuit, you can use small containers with horizontal or vertical mounting.

DIY expansion tank

Is it possible and how to make an expansion tank for heating? Due to the complexity of the closed-type design at home, it is difficult to make it. Therefore, we will consider the technology and procedure for welding an open heating container.

It is best to choose sheets of stainless iron as the material of manufacture. However, it may be difficult to weld them. Therefore, for the production of an expansion tank for heating only with their own hands, galvanized metal is most often used. The thickness of the sheets is usually between 0.8 and 1.5 mm.

The volume of the structure should be 5% of the total amount of water in the system. You also need to take into account the degree of expansion of the coolant. For water, this indicator is 0.3% for every 10 °, i.e. if the total volume of the coolant is 300 liters, then the capacity of the expansion tank must be at least 15 liters. Based on these data, the dimensions of the future structure are determined.

In order to make an expansion tank for heating yourself, you need to perform the following steps:

- Draw up a drawing taking into account the calculated volume of the container;

- Using the "grinder" cut out the blanks from the sheets. It must be remembered that when the welds are formed, the actual dimensions of the tank will be smaller;

- Holes are cut out for subsequent welding of the nozzles, their installation is performed;

- Joining the walls of the structure, checking the tightness.

It is recommended to install the top cover to keep out debris and prevent the evaporation of the thermal fluid. With its help, you can carry out an audit of an open-type expansion tank.

The installation of a homemade heating expansion tank can only be done after the entire system has been installed. Otherwise, there is a high probability of mismatch of the pipes.

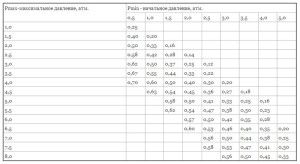

Calculation of the diaphragm tank

Before installing an expansion tank with a membrane in the heating system, you need to calculate its volume. A simple circuit for an open container is not suitable in this case. To do this, you need to use a different technique.

The defining parameter will be the filling factor of the closed expansion tank. First, you need to calculate the maximum volume of water expansion in the system using the following formula:

Where E - Coefficient of thermal expansion,FROM - The total volume of the coolant in the system,Rmin - Initial pressure in the system,Rmax - The maximum allowable pressure value,Kzap - Tank filling factor at different pressures. The data is taken from the table.

Pressure readings must be accurate. Otherwise, regardless of the location of the expansion tank in the heating system, it will not perform its functions or will quickly fail. It is recommended to add 5% for the stock to the resulting calculated indicators. It may be required when installing additional sections of radiators in the system and increasing the total volume of the coolant.

Before purchasing a membrane tank, you need to read the instructions from the manufacturer. It specifies the selection and installation features for this model.

Expansion tank installation

After making miscalculations, you can start installing the heating expansion tank. It is important to choose the right location on the general scheme. It directly depends on the type of system - gravitational or forced circulation. Despite the fact that the role of the expansion tank in heating will remain unchanged, incorrect installation can lead to malfunctions.

Open design

The installation of an open-air expansion tank is carried out at the highest point of the system.

Some experts recommend installing it immediately after the accelerating vertical line. By adding water to the system through the expansion tank, the likelihood of a reverse stroke is reduced. Also, in this place of the circuit, the highest temperature of the coolant is usually and, accordingly, its expansion. You can also make a connection to the return pipe. But then the operation of the expansion tank in the heating system will be less efficient.

Before installation, we recommend that you familiarize yourself with the general rules and tips:

- Minor horizontal and vertical deviations of the structure are allowed. But they should not exceed 2-3 °;

- Warming can be done with basalt wool. She is not afraid of humidity, and most importantly, high temperatures;

- In the event of a critical excess of pressure inside the heating expansion tank, part of the liquid can get through the top cover onto the floor of the attic. It is recommended to make an improved waterproofing of the floor in this place.

A scheduled inspection of the tank condition can be done 2 times a month with constant heating operation and always before the first start of the system.

Diaphragm tank

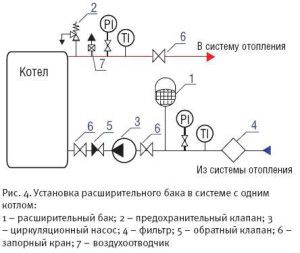

Installation of a membrane expansion tank in heating systems is carried out only on the return pipe in front of the circulation pump.

A prerequisite is compliance with the temperature regime in the room. The air heating level should not be less than + 5 ° С. Installation should not be impeded by foreign objects. The same applies to the maintenance of the structure.

Correct installation of the expansion tank in the heating system consists in observing its level. The structure must stand strictly upright. Even a slight tilt can cause malfunctions. For the safety of service, an air valve should be installed on the air chamber to quickly release the pressure in it in the event of an emergency.

It must be remembered that the location of the expansion tank in the heating system must be not only technically correct, but also convenient for its maintenance.

The fundamental difference between the operation of the expansion tank in a closed-type heating system is the possibility of its quick dismantling. Therefore, it is recommended to install 2 shut-off valves during installation - one on the supply pipe to the heating system, and the other on the water chamber of the tank. By closing them, you can quickly dismantle the container to carry out repairs or install a new one.

The video material presents the design features of expansion tanks and their role in the operation of the heating system:

![827045880f83 [1]](https://ihousetop.decorexpro.com/wp-content/uploads/2015/03/827045880f831.jpg)