During the operation of the heating system, it is necessary to change the parameters of the pressure and temperature of the coolant. This may be due to several factors - overheating of hot water, uneven hydraulic distribution. To solve these problems, you should install temperature and pressure regulators for the heating system.

Heating temperature control devices

Most often it is necessary to change the temperature parameters in the heating system. This can be done both comprehensively for the entire network, and for each device separately. Therefore, in critical sections of the highway, a mechanical temperature controller for heating or its electronic analogue is needed.

What tasks should these devices perform? First of all - control and timely change of the temperature regime in the system. Depending on the design and field of application, temperature controllers for radiators and the entire heat supply as a whole can be of several types:

- Controllers for the entire heating system... These include the weather heating controller, which is connected directly to the boiler or the distribution unit of the system;

- Zone effect thermostats... This function is performed by the radiator regulator, which limits the flow of heat carrier depending on the current temperature readings.

Each of these classes of devices is structurally cast and has its own individual installation scheme. Therefore, for the correct assembly of heat supply, it is necessary to understand the specifics of all types of thermostats.

Experts recommend purchasing heating radiators with a temperature controller. This will not only save money, but also eliminate the likelihood of buying the wrong model.

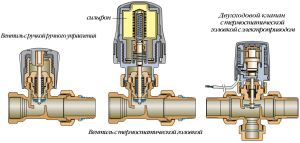

Mechanical heating thermostats

The mechanical regulator of the radiator is the simplest and most reliable device for semi-automatic and automatic control of the heating of the radiator surface. It consists of two interconnected units - shut-off valves and a control thermal head.

In the housing of the control part there is a temperature-sensitive element that changes its dimensions under the influence of temperature. It is connected to a needle valve that restricts the flow of the heating medium. To control the change in valve position, the heating regulator in the apartment has a spiral spring, which is connected to the adjusting knob. Turning it increases or decreases the degree of pressure of the spring to the heat-sensitive element, thereby setting the response temperature of the device.

The advantages of using a mechanical temperature controller for heating are as follows:

- The ability to adjust the heating of a separate radiator without affecting the parameters of the entire system;

- Simple installation and maintenance. This work can be performed even by a non-specialist. It is only important to familiarize yourself with the instructions for installing temperature regulators in heating radiators;

- The design is designed for all types of radiators - steel, aluminum, bimetallic and cast iron. However, installing the regulator in a cast-iron radiator is not always advisable. This material has a high heat capacity.

The main difficulty in installing heating radiators with a temperature controller is the correct location of the control element. Do not allow hot air from pipes or batteries to affect the temperature-sensitive element. This will cause it to malfunction.

The technology for installing a mechanical temperature controller for heat supply may vary depending on the design of the battery and the way it is connected to heating.

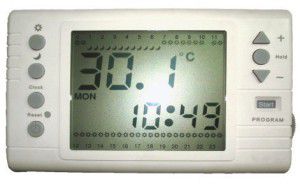

Electronic heating programmers

Weather controllers for heating have much more functionality. They consist of an electronic control unit that can be connected to other heat supply elements - a boiler, thermostats, circulation pumps.

The principle of operation of electronic heating controllers in an apartment differs from mechanical ones. They process the readings of the built-in or external thermometers to transmit commands to the control elements. So, when the temperature in a separate room changes, a command is sent to the servo drive of the heating radiator regulator, which in turn changes the position of the needle valve.

The specificity of the functioning of the weather regulator of heat supply is expressed in the following nuances:

- Providing a constant supply of electricity for the operation of the device;

- Connection to other heating elements can be carried out if the heating regulator device in the apartment has the appropriate connectors;

- Changing the parameters of the controller depends on the factory settings. Some models for heating radiators with a temperature controller have permanent settings. Complex programmers feature flexible software.

To organize remote control of the heating controller in the house, you can install a GPS module. With its help, data on the state of the system will be transmitted to the user in the form of SMS. Reverse heating control is carried out in the same way. The manual heating temperature controller does not have such a function a priori.

The setting of temperature controllers for heating radiators is carried out based on the design parameters of the system. Otherwise, the device may not function correctly.

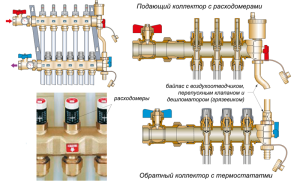

Thermostats in heating collectors

In addition to installing manual heating temperature controllers in batteries, they are used to complete collector heat supply. Their installation is carried out both in the central distribution manifolds and in the control unit for the water underfloor heating system.

Unlike regulators for heating radiators, in the collector group they perform the function of controlling the volume of the coolant flow into individual heating circuits. Therefore, the requirements for the design and its functionality are somewhat higher than those of devices designed for completing batteries.

There are several types of thermostats for collector groups:

- Manual regulators of heating supply temperature... Structurally, they are no different from similar devices for batteries. The difference is in the size of the connecting pipe and the temperature range of operation. They are inconvenient in operation, since you have to manually adjust the parameters for a separate circuit;

- Thermostats with servo drive... They are often connected to an external control module. Changing the position of the damper occurs only when a command from the programmer is received. Options with the installation of an external temperature sensor are possible. This is most often done to organize mixing units.

The installation and operation of such thermostats will make it possible to achieve precise adjustment of individual heating circuits. Thus, you can save on energy costs and optimize the operation of the entire system as a whole.

There are two types of thermostats for collector heating - with removable servos and stationary. The choice depends on the required functionality of the system.

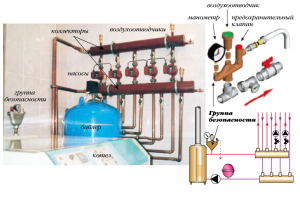

Heating pressure regulators

In a closed heat supply system, in addition to temperature, there is another equally important indicator - pressure. As a result of heating the coolant, it expands. On the one hand, this phenomenon contributes to better circulation of hot water. But if you do not install a pressure regulator for heating, an emergency situation may occur.

The normal value of this parameter ranges from 2 to 5 atm. depending on the type of heating system. In centralized highways, a short-term overpressure of up to 10 atm is possible. To stabilize it, the pressure regulator of the heating system is intended.

Currently, there are several types of these devices that differ not only in appearance, but also in functionality:

- Drain valve... Removes excess heating medium for pressure compensation;

- Air vent... Designed for the timely elimination of air congestion. They are formed due to overheating of hot water and can lead to emergencies;

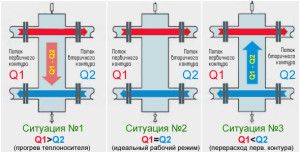

- Hydrostrel... This water pressure regulator in the heating system is used not only for collector systems, but also in two-pipe circuits. It stabilizes the pressure between the heating supply and return pipes.

In addition to the hydraulic arrow, all other devices for regulating the water pressure in the heating system have variable response parameters. Those. the user can set the pressure limit values by himself, upon the appearance of which the regulating element is activated.

Expansion vessel for stabilizing heating pressure

The expansion vessel has a key influence on the stability of a closed forced circulation heating system. It is designed to automatically compensate for the resulting excess pressure on pipes and radiators.

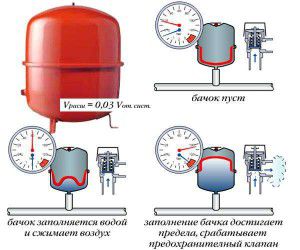

Structurally, this device for regulating the pressure in heating is a container divided into two parts by an elastic membrane. One of the cavities is connected to the heating with a pipe, and air is injected into the second. In this case, the value of the pressure in the second should be less than the maximum allowable by 5-10%.

The principle of operation of the membrane pressure regulator of the heating system can be described by the following algorithm:

- The pressure in the system is normal - the membrane does not change its position.

- A critical expansion of the coolant has occurred. At the same time, the membrane moves towards the air chamber, thereby increasing the total volume of heat supply. Overpressure is compensated.

- A sharp drop in the volume of the coolant. The water pressure regulator in heating reduces the volume by displacing the membrane towards the water chamber. This occurs under the influence of the pressure of the air chamber.

In this way, the pressure in the heating system is automatically regulated. When choosing a model of an expansion tank, it is necessary to take into account the possibility of replacing the elastic membrane. There are models where the user can do it himself. But for tanks with a small volume, this is not possible. After two or three seasons of operation, you have to dismantle the old heating module and install a new one.

How to correctly calculate the parameters of devices for regulating the pressure and temperature of heating? To do this, it is recommended to use specialized software packages. The characteristics of the house (degree of insulation), a graphical diagram of the location of pipes, radiators and other components of heat supply are preliminarily entered. Based on the data obtained, the program will give the optimal parameters for all elements.

In the video, you can familiarize yourself with the specifics of connecting a room temperature controller in heating: