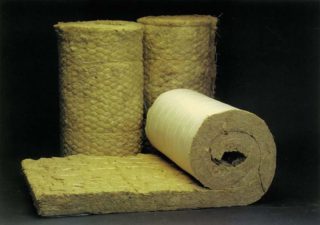

There are two large groups of heaters - slab and roll. Each variety is used depending on the operating conditions. Roll insulation is most effective when finishing extended sections and structures of complex shapes. This is achieved due to the high density and flexibility of the material. The rolls are compact, easy to transport and store. The installation process itself is also straightforward. The main thing is not to leave gaps between adjacent sheets of the heat insulator.

Mineral wool and varieties of insulation from it

The use of mineral wool in rolls for insulating various structures has been widely used due to the excellent thermal insulation properties of the material and the ease of working with it, as well as other positive qualities: low weight, non-combustibility and low cost.

Using mineral wool supplied in rolls, you can quickly and easily insulate your floor or roof. However, for different cases, you should choose a mineral wool with certain characteristics. The varieties of mineral wool include the following types of insulation:

- The structure of the basalt insulation, supplied in compact rolls, is the finest fiberglass. It is obtained by melting rocks of mountain origin.

- The cheapest and still demanded variety is glass wool. The fibers of this insulation are made on the basis of waste from the glass industry. There are wall and roofing.

- Slag wool is made from the waste of the metallurgical industry.

Basalt mineral wool in rolls is resistant to high temperatures, is not afraid of moisture, does not emit toxins when heated, and is lightweight.

The peculiarity of glass wool is its incombustibility and high soundproofing properties. It is necessary to work with this material with gloves, goggles and a respirator to protect against fine glass dust. The downside is the lack of moisture resistance, so the insulation must be additionally protected from moisture, which is not always economically beneficial.

A feature of slag mineral wool roll is its low price and high heat and sound insulation properties. This type of rolled mineral wool insulation for walls has the highest density and weight.

Insulation with a foil layer

Foil insulation in rolls is a two-layer combined material. It consists of expanded polyethylene, expanded polystyrene or cork, and an outer layer of polished foil. The combination of these two materials made it possible to create a light, thin and effective insulation for the enclosing structures on the inside of the premises. It provides high-quality protection of the coating from UV rays and moisture.

Foil roll thermal insulation differs in the material of the substrate. The following varieties are on sale:

- With a backing made of expanded polystyrene - the most popular, practical and inexpensive material. However, its thermal insulation properties are not as high as that of foamed polyethylene.

- With a backing made of polyethylene foam - a lightweight porous material.

- With a cork backing - the most expensive and natural coating, with excellent heat and sound insulation properties.

The outer reflective layer is made of foil or metallized spraying. The second option has less reflection, but it perfectly traps steam, so this material is relevant in rooms with high humidity. The spraying strength is less than that of foil.

The main advantages of foil rolled polystyrene foam and other types of substrates with a reflective layer include the following:

- Small thickness and low weight.

- The ability to create an even surface, which is especially important when arranging a water floor, laying laminate and other floor coverings.

- Flexibility, thanks to which it is possible to insulate not only smooth, but also complex structures.

- Easy installation without a frame. Fastening is carried out using an adhesive or polyurethane foam.

Foil thin substrates are indispensable when installing a warm water floor. Heating water or electrical circuits are positioned at the top and the heat is transferred up into the room and not down.

Mezhventsovy heat insulator and its features

A separate type of flexible insulation is designed to fill voids in the inter-row space of log and log houses. A distinctive feature of the material is its small width, which facilitates the installation process. The material is made from natural raw materials - batting, jute, flax.

It is possible to use such thermal insulation in comfortable narrow rolls not only during the construction of a new house, but also after a few months / years.

Purpose and application of roll insulation

Roll insulation is a versatile material, so it can be used for a wide range of construction and finishing works.

Walls

Thin lightweight heat-insulating material allows you to insulate, soundproof and level the walls for decoration with wallpaper or wall panels. The material is cut into separate canvases and glued to the cleaned, dust-free wall. As an adhesive, a composition containing cement is used, which provides high adhesion to the substrate.

Pipes

Most often, foil insulation is used to insulate pipes of the underfloor heating system. It is laid on a flat prepared base. The water contours are fixed from above. During heating, thermal energy is reflected from the substrate and directed upward. Thus, heat loss through the bottom ceiling is excluded, and the system itself becomes economically viable and efficient.

Roof

The widespread use of roll insulation for roof insulation is associated with the complex structure of the rafter system. This material is great for flat and pitched roofs.

Thin foil material is also used to insulate enclosing structures on loggias and balconies. With a sufficient area and height of the room, mineral wool is used, which is placed between the elements of the lathing from the bar. Using a piece of foil-clad insulation, you can make a reflective screen for a heating radiator.

Material from popular manufacturers

There are materials from different manufacturers on sale. Among them there are leaders whose impeccable quality has been tested over the years:

- Knauf. Mineral wool from a German manufacturer has low thermal conductivity and excellent sound insulation performance.

- Izover. Material from a French manufacturer of a wide range of applications, thanks to the thickness of 2 - 15 cm. There are options with a foil layer.

- Ursa. The material has a long service life and excellent sound insulation properties.Does not burn and does not emit toxins when heated, has elasticity. It is used in private homes and industrial facilities.

Foil materials also include Penofol and Topizol.

When choosing a heater, one should take into account the requirements for the thermal insulation of the room and the operating conditions. Not all materials are moisture resistant, therefore they need additional protection with waterproofing materials.