Polyfoam has long been successfully used as an inexpensive and effective insulation for the facades of residential and industrial buildings, including private buildings. This material provides good thermal insulation, is lightweight and does not cause problems during the installation process, which allows it to be used even by novices in the construction industry. External wall insulation with foam plastic makes it possible to significantly reduce heating costs and create an ideal microclimate in the room. Before the procedure, it is worth examining all the pros and cons of such thermal insulation, choosing the appropriate type of material and identifying the main nuances of the installation technology.

Pros and cons of foam for external insulation

Polyfoam is a lightweight material, its structure is a foamed mass, the main volume of which is air. The density of the foam is much lower than the density of the raw materials from which it is produced. The high air content is an undoubted advantage of foam plastic, due to which it has good sound and thermal insulation properties. This is a budget, convenient and lightweight insulation that does not cause difficulties during installation.

Foam plates are used taking into account the levels of their strength, at minimum rates, additional protection is used and the material is mounted in combination with the frame installation method. Polyfoam of increased strength is already protected from mechanical damage, but in this case it will also not hurt to install the frame.

The list of advantages of foam boards include:

- resistance to water, inability to absorb liquid;

- resistance to the formation of fungi and mold;

- no problems during cutting and installation due to low weight and optimal structure;

- long service life and affordable cost;

- the ability to withstand sudden temperature changes;

- no need to install waterproofing.

If the foam is chosen for external wall decoration, it is used strictly for its intended purpose and in accordance with the installation technique. Violation of the rules will reduce to a minus all the functions of the insulation.

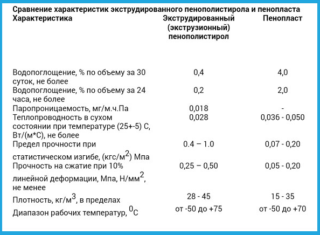

Which foam to choose

When insulating all outer walls with foam and choosing the appropriate type, its physical and technical characteristics are taken into account. It depends on them how well the plates will keep cool and warm, whether problems arise during installation, the factor of environmental friendliness and safety for health is also of great importance. The thickness of the slabs depends on the type of structure and the climate of the region, it is better to choose the average value of the sheets no more than 10 cm. In stores you can find slabs with dimensions of 40, 50 and 100 mm, they are made to order with other parameters.

It is better to insulate the facade with plates of standard dimensions: 500x1000, 1000x1000 and 1000x2000 mm. They are applied to the walls as a whole, cutting the material for the openings of doors and windows with a knife or file. The density of the foam is its main parameter, on which the scope of application of the sheets directly depends. For construction needs, slabs of three types are produced, designated by numbers - 15, 25 and 35, intended for the frame method, insulation using the "wet facade" technique and horizontal surfaces, respectively.

Polyfoam is able to ignite only under the influence of an open fire, the time of its self-burning lasts no more than 3-4 seconds.Expanded polystyrene is a more toxic material that emits toxic substances when burned.

Surface preparation

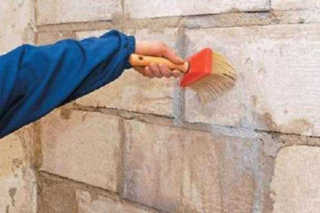

Thermal insulation of a house with polystyrene begins with the preparation and leveling of the surface, the walls should be perfectly even with minor errors of up to 2 cm.After cleaning, each wall is primed, covered with plaster or processed using a concrete contact, polystyrene plates are prepared additionally and made a little rough using a special roller. This procedure is carried out strictly according to the instructions for insulating external walls with foam.

In order to install the slabs as evenly as possible on the facade, the zero level is beaten off in a circle so that the first rows of sheets lie horizontally. The plinth profile provides additional protection against insects and rodents, so its installation should not be neglected. The finishing technology implies its installation using a special level, a zero point is marked on the facade along the perimeter of the profile attachment, after the point, they are tied together using a chopping cord.

Styrofoam installation technology

Laying begins with window or door slopes, then proceed to the installation of the first row, the position of which is fixed with a basement profile. Plates are mounted in a checkerboard pattern, while paying attention to how tightly they will be fixed. Styrofoam sheets are fixed with dowels, like foam. When fixing the dowels, the following rules must be observed:

- the glue must dry completely, the structure is left for a day before proceeding to the next stage;

- dowels are driven into each corner at the junction of several plates, in order to fix three sheets, one piece will be enough;

- the first dowel is driven into the central part of the sheet, the rest are in the corners.

Using foam or expanded polystyrene as insulation for walls, you need to take into account the service life of the plates and observe safety precautions. In this case, the insulation will retain its properties throughout the entire period of operation.

Finishing

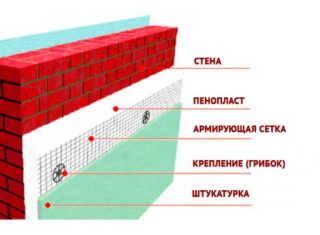

At the final stage of finishing, they are engaged in sealing the seams and covering the walls with plaster or processing according to the scheme using the siding technique. It is necessary to close all seams to prevent cold air from entering the gaps between the foam sheets. Large gaps are filled with polyurethane foam, small ones can be covered with a layer of special plaster. It must be applied to a layer of reinforced mesh, otherwise it will not stick to the wall. The mesh is leveled quickly, since the glue is able to set instantly, so that it is completely covered with plaster, the insulation will need to be covered.

Each layer must be applied after the first has completely dried, using a smooth type spatula for this purpose. You can take any paint suitable for outdoor structures; it is applied to the facade using a foam rubber roller. This stage is final. Styrofoam has much more pros than cons compared to expanded polystyrene. It is able to retain heat well inside the room, it also does not get wet and does not create a load on the foundation.

It is more advisable to use polystyrene for external wall decoration; when used internally, the insulation spreads an unpleasant odor, which is why it is considered not environmentally friendly enough.

Insulation thickness

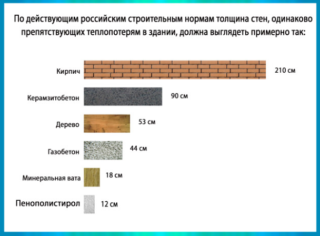

To create high-quality thermal insulation, the thickness of the foam must be optimal. It depends on many factors, including the climatic zone in which the building is located, the thickness of its walls and the material from which they are made. The most important parameter is considered to be the thermal resistance of external walls, it is a constant value, the value of which is presented in the regulatory tables. This parameter can be determined by dividing the thickness of the foam by its thermal conductivity coefficient. Such a calculation will help you find out the required thickness of the material required to insulate a particular building in a particular climatic zone.

If the house is composed of one and a half layers of ceramic bricks, for such a building the value will be 1.06 m2K / W, the difference in parameters is compensated for with the help of insulation. In this case, the value of the thermal resistance will be 2.02 m2K / V. Taking into account the fact that the thermal conductivity of a good foam is 0.039 W (m * K), after multiplying this value by the value of thermal conductivity, the required thickness of the insulation sheet is found out, as a result, the required thickness will be 78 mm. It is necessary to consider what sizes of foam are on sale. Most often, sheets with a thickness of 50 and 100 mm are used, in this case one side of the wall will be 1000 mm, the second 500, 1000 or 2000.

The process of insulating the outer walls can be carried out independently. The time spent on work will depend on the experience of the builder, although anyone can handle this procedure with the necessary skills. The outer walls of the house itself, the attic or the veranda can be insulated with polystyrene or expanded polystyrene.

The base layer should be done according to standard, while the top wall finish can be almost any, depending on the overall design and style of the building. The standard service life of polystyrene is from 20 to 40 years, it directly depends on the quality of materials and installation technique. When handled correctly, the material can withstand 700 freeze and thaw cycles. Compliance with all the rules and strict adherence to step-by-step instructions will help to avoid gross mistakes at all stages.