The air valve for heating is an integral part of all existing heating systems, including underfloor heating. If it is present, it is possible to manually or automatically get rid of the air accumulating in the pipes and radiators of closed-type circuits. Familiarity with its structure and principle of operation will help you to choose the right air drain valve for the heating system.

Air bleed valve required

The need for a valve for venting air from the heating system or a special air vent is due to the following reasons:

- the need to bleed air droplets that, for one reason or another, accumulate in heating systems (including warm floors);

- elimination of uneven heating of radiators arising from the formation of air "jams";

- the need to protect problem areas of the pipeline laid in the area of the ceilings of the premises (at the maximum possible height).

At points highly elevated above the floor, the likelihood of air jams formation increases dramatically. If you do not remove them in a timely manner, this will interfere with the normal circulation of the coolant and create an obstacle for high-quality heating of the home.

Danger of air congestion

Small air droplets, dissolving in the carrier circulating through the pipes, can eventually destroy them along with batteries and other equipment elements. The corrosive effect of decomposed air on molecules increases significantly due to the high oxygen content. The gases that appear in the pipeline and batteries accelerate the corrosion process and form air pockets that interfere with the normal functioning of the heating system. In technical terms, this is manifested as follows:

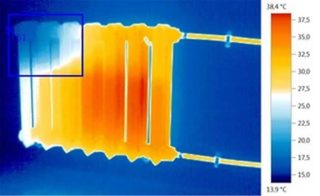

- The accumulations formed in the upper part of the system turn into a kind of "thermal insulation barrier" that reduces the amount of heat generated to heat the room.

- For the same reason, the intensity of the circulation of the coolant decreases. In adverse conditions, its movement through the pipeline is completely blocked, which causes rapid cooling of the batteries and the shutdown of the entire system.

- The pumping equipment installed in the heating circuit is not always designed to work with a carrier in which there are a large number of air molecules.

In the presence of traffic jams, the circulation of the carrier along the heating circuit is accompanied by unpleasant gurgling sounds that tire the residents of an apartment or house.

Types of air valves

The Mayevsky crane is a type of air vents designed to manually remove air particles.In addition, they are mounted in hard-to-reach areas of the pipeline, where the installation of a typical valve for one reason or another is impossible. According to the place and method of placement, these devices are divided into the following types:

- straight-through;

- corner.

Straight valve devices are similar in appearance to an ordinary candle. They are installed vertically in a designated place in a pipeline section or in a safety group. Devices of the second type differ from those described by the presence of an angular interface, which allows them to be more conveniently and compactly placed on the radiator. During installation, special attention is paid to the strictly vertical position of the outlet section (descent).

Device and principle of operation

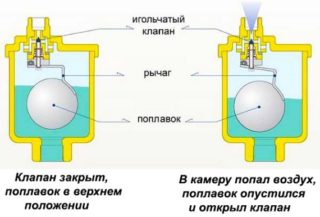

The automatic device has a very simple design. Consists of the following main parts:

- a body made of durable and non-corrosive metal (most often bronze or stainless steel);

- a cover with a calibrated hole for bleeding accumulated air;

- a float placed inside the housing.

The operating principle of the automatic air valve is simple. The air accumulating in the system gradually displaces in its direction, where it acts on the float located in the chamber, slightly raising it. Above the guides, there is a bleed hole through which air bubbles under the pressure of water masses come out.

The specificity of the devices lies in the fact that for normal operation, the bleeding mechanism should be located at the highest point of the pipeline network. Air, light in comparison with water, rushes into this part of the system. If there is no such point, the automatic valve will not work. In this situation, it will be necessary to provide for the installation of a manual air vent such as a Mayevsky crane.

Pros and cons of using

Benefits of installing an air valve:

- if present, the likelihood of damage to pipelines and batteries is reduced;

- it is possible to evenly distribute heat over the piping elements (radiator batteries, in particular);

- the humidity in the heated room is normalized, there is practically no condensation in it;

- the likelihood of the appearance and reproduction of mold and fungi is reduced.

Most of the well-known models can be assembled independently, which allows you to save on payment for the services of specialists.

The presence of many advantages does not exclude the negative aspects of using an air bleed valve.

- In severe frosts, some models freeze and stop working normally.

- Manual valve train designs require constant human intervention.

- There are too many factors to consider when adjusting the device manually.

- Some models of automatic devices are equipped with a not very reliable electric drive.

- The valve location is not very convenient for service.

- In the absence of a special filter, dust and many small particles accumulate in the system, impairing its operation.

Most disadvantages can be avoided by taking appropriate precautions. Often they boil down to the purchase of automatic valves equipped with replaceable fine filters. When considering the pros and cons, it is noted that the advantages prevail over the easily remedied disadvantages.

Features of the installation of valves for air bleeding

When installing the air valve, the following factors must be taken into account:

- Air in heating systems accumulates at the highest points of the heating equipment circuit. This feature is typical not only for radiators, but also for underfloor heating collectors and heating boilers of various types.

- If the location for the installation of the air damper is incorrectly selected, the thermal balance is disturbed, the efficiency of heating the premises is sharply reduced.For the underfloor heating system, this violation is accompanied by the appearance of zones with more or less heating.

To avoid the undesirable consequences of mistakes made during installation, it is important to know that automatic and manual air insulated valves are installed in the following places:

- on collectors of floor heating equipment;

- in the area of the pump-mixing block of the heating boiler;

- on standard batteries;

- on other auxiliary equipment of heating boilers (the highest point located near the expansion tank is selected);

In addition, the place where the KVU insulated valve is installed is often a hydraulic arrow.