The operation of an autonomous heating system may not always be stable. Sudden changes in temperature and, as a result, pressure, affect the integrity of the connection of pipes and radiators. To prevent this, a special protective device is needed - a safety valve for the heating system: its selection, installation is included in the mandatory list of installation work.

Bypass valve functions

During the heating of the coolant, it expands - a natural increase in volume leads to an increase in pressure on the inner walls of pipelines and heating devices. Exceeding a certain value (usually about 3.5 bar) breaks the tightness of the joints, which leads to gusts and emergencies. For the timely discharge of excess hot water, it is necessary to install a safety valve for the heating boiler, or, as it is also called, a bypass valve.

It should perform the following functions:

- Remove excess coolant in a timely manner, while reducing the pressure inside the system;

- Have the ability to customize. In an autonomous system of a private house, the safety valve for heating must have the function of manually setting the maximum allowable pressure value;

- Operational reliability. The construction and material of manufacture must ensure the normal operation of the safety valve for the heating system.

The choice of a specific model is influenced by the characteristics of heat supply - the value of the optimal and maximum pressure in the pipes, the location of the expansion tank, the length of the line and its type (one-pipe, two-pipe or collector). But before purchasing a device, you need to study the parameters that characterize the safety valve for heating: the principle of operation, design and installation specifics.

Types and design features of valves for heating

Currently, for the operation of bypass valves, two principles of operation that are different in their essence are used - spring and lever-cargo. The latter is most often used for large central heating lines. Let's consider the specifics of the work of each of them.

Spring valves

This heating system relief valve is installed in private homes and apartments.

The principle of this mechanism is as follows. The flow of liquid acts on the valve of the capan, the movement of which is limited by a spring. As soon as the pressure value exceeds the compression force of the spring, the rod will rise up. As a result, the coolant will enter the outlet. After stabilization of the internal water volume, the spring of the safety valve for the heating boiler will return the shutter to its original position. As a result, the coolant flow ceases to flow into the outlet.

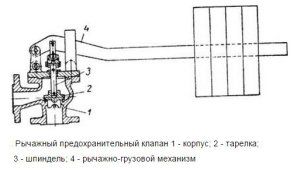

Lever-weight valve

This type of relief safety device is used for pipelines with large diameters (from 200 mm). In it, instead of a spring, a load with a different mass exerts a force on the rod.

Before choosing a safety valve for a heating system with a similar design, you must familiarize yourself with the specifics of its operation.First of all, this is a coarse setting of the critical pressure value. This can be done by changing the mass on the outer arm. On spring models, this can be done by turning the adjusting cap. Moreover, the minimum change in the pressure value can be 0.2 bar.

Choosing the optimal model

The process for selecting a safety valve for a heating system should be based on its performance. To do this, in addition to heating parameters, you need to familiarize yourself with the regulatory document - GOST 24570-81, which describes in detail the selection criteria.

Since lever-load mechanisms are used in large pipelines, the conditions for spring models of a safety valve for a heating boiler will be considered. They are divided into several main points - the requirements for the mechanism, piping and material of manufacture.

Mechanism

In the design of the bypass valve, the main elements are a spring, a stem and a plate, which is affected by the pressure of the coolant. Together, they should form a reliable mechanism with precisely calculated parameters. The main ones are the conditions for the operation of the safety valve for the heating system, selection, installation.

There are two stages in the operation of the device - the time of the beginning of the movement of the stem and the complete opening of the passage to remove excess water. The percentage difference in the pressure value between them is the main characteristic of the valve. In addition, it depends on the nominal pressure in the heating system.

- Up to 0.25 MPa - 15%;

- Over 0.25 MPa - 10%.

The higher the operating pressure, the faster the device should respond. In this case, the coils of the spring of the safety valve for heating must not come into contact with each other.

The control mechanism is necessarily protected from the direct influence of hot water.

Since during a long idle time, the spring may "stick", the device must have a mechanism for checking its performance (a rod for manually pulling the spring back).

Pipeline supply

Before choosing a safety valve for a heating system, you need to correctly determine its diameter. It should not be less than the inlet pipe itself. Otherwise, the hydraulic resistance will not allow the device to perform its functions normally. It is imperative that the safety relief valve for the heating system be protected against freezing - the effect of freezing temperatures negatively affects the operation.

During installation, the safety valve of the heating system must only slope towards the boiler. This will ensure minimal hydraulic loss when pressure is applied to the tray.

Manufacturing material

The body is most often made of brass, since this material has a minimum coefficient of thermal expansion, is reliable and affordable in financial terms. The selection of the safety valve of the heating system for this parameter is very important - when the maximum pressure is reached, the body should not collapse.

For the heating safety valve, the principle of operation also lies in the timely setting of the response pressure value. To do this as quickly as possible, the regulating block is made of special heat-resistant plastic. It does not change its geometry and remains rigid even at the maximum water temperature.

Features of the installation of the safety valve

Professional installation of a safety valve in a heating system is to take into account not only its characteristics, but also the operation of the expansion tank. As soon as the latter cannot expand the internal volume of the pipes, the bypass valve should work and remove excess water from the pipes.

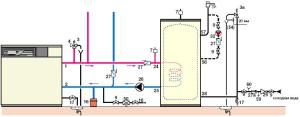

According to the rules, the relief safety valve for the heating system must be installed immediately after the outlet of the boiler (in the diagram, these are elements 3 and 4). The optimum distance between them is 20-30 cm. For visual control, a pressure gauge is mounted in front of it. According to its readings, you can determine the current state of the system.

There are certain rules for installing a safety valve in a heating system:

- Do not install shut-off equipment in front of the device and the boiler - valves, taps, etc.;

- To remove excess water, a drain pipe is installed at the outlet of the correctly selected heating safety valve. It can be connected to a return or sewer pipe;

- In a closed gravity system, the heating safety valve is installed at the highest point.

In addition, it is necessary to periodically check the condition of the mechanism. Spring models are characterized by "sticking" of the plate to the walls of the body. This increases the value of the maximum opening pressure of the safety valve in the heating system. As a result, if the permissible pressure value is exceeded, the device will not work.

If the number of emergency descents was 7-8 times, experts recommend replacing the valve. This is due to the natural wear and tear of the spring and plate.

To a greater extent, the latter relates to the operating conditions of the safety valve for heating than to the principle of its operation. However, without this, even with a perfectly executed installation, the likelihood of incorrect operation of the device increases.

What should be considered when selecting a safety valve for an autonomous heating system? Compliance of its technical characteristics with operational ones. It is also important to properly connect it to the pipe. The best way to do this is to use a traditional pipe tow. The FUM tape may not withstand the temperature effect, as a result of which a leak will appear.

For a better understanding of the principle of operation of the safety valve, it is recommended to watch a video about the design and operation of the spring model: