Infrared underfloor heating is one of the many electric space heating systems in which the floor itself acts as a heater. Compared to electrical conductive and cable options, the system, which is based on the use of infrared heating film, has undeniable advantages, due to which it is in considerable demand.

Operating principle

The principle of operation of an infrared film heater is based on the conversion of electrical energy into infrared radiation. Unlike traditional heaters, which heat the surrounding air due to convective heat exchange, infrared rays, when emitted, heat not the surrounding air, but objects and the human body. The air heats up by receiving heat from objects in contact with infrared waves.

IR radiation is a part of the light spectrum inaccessible to the human eye. The emitted infrared wavelengths range from 5 to 20 microns. Infrared radiation is harmless to humans, which allows it to be used not only in industry and medicine, but also in everyday life.

System design and working algorithm

Structurally, an IR warm floor is a heating sheet made of an elastic polymer film with a thickness of no more than 400 microns, on one side of which the thinnest conductive carbon (carbon) tracks are applied. They are made in the form of transverse stripes or honeycombs. When an electric current passes, these paths heat up and begin to generate infrared waves. This generates heat, which is transferred to the floor covering and / or surrounding objects.

The consumer may come across an infrared film with a continuous layer of deposited carbon. Such a film is more reliable and durable, but its cost is much higher.

Power supply to the conductive paths is supplied through the conductors located at the edges of the infrared fabric. They are made of silvered copper.

Live conductors are protected from moisture and other damage by a durable hydrophobic coating that does not interfere with the passage of infrared rays.

Mandatory attributes of an infrared floor are also:

- thermostat;

- temperature sensor.

The regulator in conjunction with the sensor is designed to control and optimize the functioning of the entire system. The efficiency and economy of its work depends on it. The system, depending on the version, is completed with devices of various functional capabilities - from the simplest one, capable of protecting live parts from overheating, to the latest programmer, with which the owner can set the heating temperature mode, which is valid throughout the entire heating season.

Infrared floor operates according to the following algorithm:

- Applying power to the foil causes the flooring to heat up.

- After the temperature in the area of the temperature sensor reaches the preset one, the latter will give a command to the thermostat to turn off the power supply.

- The temperature controller cuts off the power supply and the heating element cools down to the temperature preset by the owner.

After the heater cools down, the thermostat will turn on the power supply and the operating cycle will repeat.

Specifications, pros and cons

In general, an infrared warm floor has the following technical parameters:

- film thickness, mm - 0.23 ... 0.47;

- web width, mm - 500 ... 1000;

- roll length, m - up to 50;

- power supply voltage, V - ~ 220;

- heating temperature, ° С - no more than 55;

- heating time of the film to the maximum temperature, sec - 20 ... 30;

- heating time of the floor covering to the specified temperature, min - no more than 40;

- melting temperature of the base, ° С - more than 210;

- power consumption, W / hour - 25 ... 35.

Comparing the technical and operational characteristics of electric heating systems, experts note a number of advantages that an infrared warm floor has.

- The film fits under any type of floor covering (laminate, carpet, etc.).

- The installation of the system is simple and easy, since it does not require any preliminary accompanying work (pouring the screed, tightening with glue, etc.).

- The absence of a screed and low film thickness do not reduce the height of the heated room.

- Simple and quick dismantling of the system in case of moving or redevelopment of premises.

- Versatility - the film can be installed not only on the floor, but also on walls or ceilings. In addition, it can be used to heat outbuildings (garage, greenhouse, etc.) and even the porch of a private house, which will prevent its icing in the winter season.

- High reliability - the manufacturer's warranty period reaches 10 years or more.

- Quiet operation.

- The efficiency of the system is close to 100%, since there are practically no heat losses;

- Uniform heating of the floor surface in a short period of time.

- In comparison with traditional heating systems, the economic effect from the use of infrared underfloor heating reaches 30 ... 35%, and in some cases, for example, when heating rooms of great height, it can reach 85%.

- Environmental Safety.

Particularly noteworthy is the higher, than with traditional heating methods, the comfort of a person's stay in a room that is heated with a warm film floor.

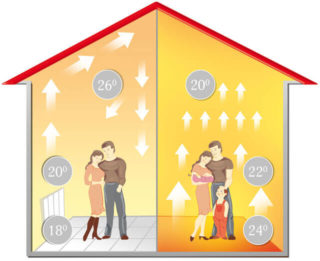

Traditional heating systems operate on the principle of convective heat transfer. In this case, first of all, the air in the heater zone is heated, which then, due to turbulent air flows, moves up to the ceiling, and the cool air goes down. Thus, the main heat energy is spent to warm up the under-ceiling space.

When a room is heated with the "Infrared warm floor" system, the situation is somewhat different. The heat radiated by the heater does not heat the air, but is immediately transferred to the floor covering and objects around it. It is in this area that people are. Warm objects heat up the air. At the surface of the floor, the air temperature corresponds to the temperature of the heated floor, warm air begins to rise evenly upward, gradually giving off heat to the objects in the room. Thus, all useful heat is concentrated in the area where a person is located (1.2 ... 2.0 m).

In such a room, a person breathes fresh and sufficiently humid air. Indeed, infrared radiation, unlike other types of heating, does not burn oxygen, which means that there are no products of its combustion and an unpleasant smell in the room. During the operation of the system, there are no turbulent air flows, which in itself prevents the spread of dust.

Like any other system, infrared floor heating is not without its drawbacks:

- the possibility of mechanical damage to a thin film during careless installation work;

- improper installation and violation of the rules of operation can lead to fire of the film;

- after turning off the system, the room cools down quickly;

- high cost of the system.

The infrared foil must not be installed under permanently installed large furniture. Violation of this rule can cause overheating and failure of the heating elements.

The choice of infrared underfloor heating

Choosing the system "Infrared warm floor", you must first of all proceed from the intended purpose and the place of installation.

- In residential premises with normal humidity, it is recommended to use a film with a power of up to 220 W / sq. m.

- For rooms with high humidity (bathroom, sauna, etc.), you need to choose a film with increased power (up to 450 W / m2) and improved insulation.

When laminate, carpet, parquet or their analogs are used as flooring, it is advisable to use a film with a power of 160 W / m2. This power is enough to provide a comfortable floor temperature and warm up the room as a whole. It is better to lay a film with a power of about 200 W / m2 under tiles or porcelain stoneware.

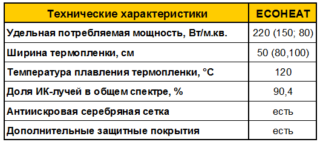

The table below will help you calculate the required system capacity:

Of no small importance when choosing a film is its quality, which largely depends on the width of the graphite strips and busbars, which should be at least 13 ... 15 mm. The film thickness is also important, which depends on the thickness of the polymer and carbon layers. The minimum allowable infrared film thickness is 0.3 mm, but the higher this value, the more durable the protective shell will be. The presence of additional layers of insulation and the use of non-combustible materials are desirable.

For heating rooms with high humidity (saunas, etc.), it is better to use a film with a continuous layer of carbon. It is distinguished by greater power, which will allow you to quickly warm up the entire room, and the presence of a water-repellent coating will avoid electric shock.

Installation of IR underfloor heating

Before proceeding with the installation of an infrared warm floor, it is necessary to perform a number of calculations and develop a layout project. In this case, the user should keep in mind that in the domestic market he can be offered 2 options:

- Complete - one box contains everything you need for installation: film, power wires, thermostat, temperature sensor, accessories for installation, etc.;

- Cut-off - a film with a width of 50, 80 or 100 cm is cut from the reel in multiples of one running meter, and all the necessary equipment is obtained by the user independently.

Layout calculation and project development

They begin the design by drawing a floor plan and indicating the areas of stationary furniture installation on it - in these places the film does not fit.

Film manufacturers recommend laying it along the long wall of the room. This will reduce the number of cuts.

In the design process, you must also take into account:

- the blade is cut in such a way that the length of one blade does not exceed 8 m;

- the distance from the wall to the infrared film should be 10 to 40 cm;

- the film should be at least 10 cm away from the furniture.

Substrate surface preparation

Before proceeding with the implementation of the developed project, it is necessary to carry out a number of measures to prepare the base on which the infrared film will be laid. The list of these works includes:

- chipping walls for laying wires and installing a temperature sensor;

- elimination of unevenness of the base with a thin layer of self-leveling floor. Permissible horizontal deviation - no more than 3 mm .;

- cleaning, washing and drying the base;

- laying a waterproofing film that protects the infrared film from moisture from below;

- insulation of the base with foil insulation (if necessary). Lay it with the metallized side down;

It is advisable to check the tightness of the junction of the walls with the floor. Existing cracks can lead to significant heat loss. Found cracks need to be "expanded", cleaned of dust and sealed with polyurethane foam.

Installation of IR film

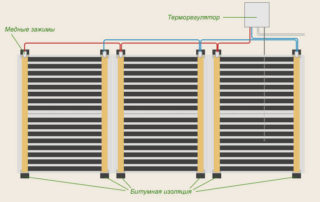

The IR-film is laid in the following order:

- They mark the floor according to the project, taking into account that the overlap of the canvases is not allowed. The recommended distance between their edges should be at least 5 cm.

- A thermal sensor is installed in the center of the heated surface, having previously deepened it into the insulation. The distance from the nearest wall to the sensor must be at least 50 cm.

- Lay the pre-cut fabric with copper strips downward in accordance with the markings.

- Fix the film to the base using small pieces of tape.

During the work, walking on the infrared film is not allowed. Also, do not put heavy objects on it or drop the tool.

Connecting system elements

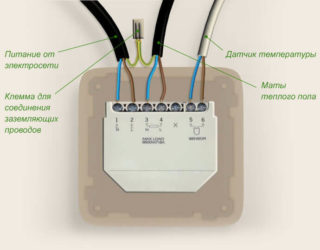

Connect the elements of the system to each other in the following sequence:

- The clamps provided in the mounting kit are connected to the ends of the copper bus.

- Electrical wires are installed and connected to the canvas, observing the condition of parallel connection without fail. The use of colored wires will help to simplify this task.

- Insulate the places of all connections. In this case, the terminals and the ends of the copper busbars on the cut sections of the web are protected with tar pads.

- Connect the thermostat to the system and then install it on the wall in an accessible place. The recommended installation height is 1 m.

- A test switch on of the system is carried out, checking the uniformity of heating. In this case, there should be no sparking and extraneous noise. If deficiencies are identified, they are eliminated.

- Only after making sure that the system is fully operational and that there are no shortcomings, you can start laying the flooring.

When performing electrical work, you must strictly observe the safety requirements set out in the operating manual for the "Infrared floor heating" system.