Polyethylene foam or foamed polyethylene (hereinafter referred to as VPE) is a synthetic material that has low thermal conductivity, therefore it is used for floor insulation, greenhouses, in the automotive industry and many other industries. It is called foamed because it has a porous structure. The material achieves such physical properties thanks to a special production technology.

Features of foamed polyethylene

To obtain a foamed insulation, the granules are poured into a melting vessel and an additive is added, then the mixture is heated and blown out, where the material cools. Then it is leveled and rolled into rolls. If you need to apply VPE on foil, do this by heating two materials, connecting them together.

This is just one technology, but there are others. Polyethylene is foamed chemically or physically, subjecting the raw material to pressure. Air cavities are formed inside, closed from each other by partitions, due to which the VPE poorly transmits heat and sound.

Material characteristics

Foamed polyethylene of different thickness is produced - from 1 to 200 mm. This material is light - its density ranges from 20 to 80 kg / cubic meter. The technical indicators are as follows:

- Temperature range from minus 60 to 100 degrees Celsius. It is impossible to operate above 100 degrees - WPE is a combustible material. When heated, it can melt, so it is most often used for protection from cold, for example, pipes are wrapped underground. At low temperatures, polyethylene foam does not change its properties.

- It is a vapor-tight film, so it is not used where there is a risk of condensation.

- It absorbs water poorly: when fully immersed in a liquid, it can collect a maximum of 3.5% moisture within a month.

- Good noise absorption. The thicker the VPE, the better the sound insulation properties.

- Chemically neutral, does not react with aggressive substances - alkalis or acids.

- In a biologically active environment, it is not exposed to fungi and bacteria. Rodents do not damage WPE when laid underground.

- It is not toxic, even when it burns it does not emit harmful substances.

- Under favorable conditions, the material can last up to 80 years.

There is one significant drawback of this material: it is afraid of exposure to ultraviolet rays, so it must be additionally insulated from the sun with a film that does not transmit rays. Under the influence of ultraviolet light, it quickly disintegrates and completely loses its beneficial properties.

Application area

10 mm of polyethylene foam can replace 50 mm of glass wool or 15 cm of brickwork, therefore it is used in construction work to insulate external walls. This reduces the overall cost of the property.

In addition to the construction site, the WPE is used:

- For wrapping various items for safe transport. Air voids inside reduce the degree of mechanical stress.

- In the production of upholstered furniture for the preservation of other materials prone to shedding.

- In light industry.

- For interior trim in the automotive industry.

- For the manufacture of sports equipment, equipment.

- Due to the strength of the material, it is used for the manufacture of prostheses, covering a metal frame with it.

The main field of application is the insulation of various objects:

- roof, foundation, walls - internal or external;

- windows, doors, floor;

- ventilation or air conditioning system.

In addition, foamed polyethylene sheet is used as a spacer between fragile items during transportation, for example, double-glazed windows for window systems.

If you put foamed PE foam behind a heating radiator, more heat will remain in the room due to the reflective properties of the foil and the low thermal conductivity of the material.

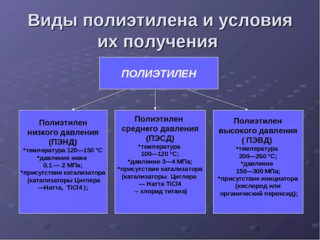

Types of polyethylene

- High pressure PE - LDPE;

- Medium pressure PE - PSD;

- Low pressure PE - HDPE;

- LPVD - linear high pressure, resistant to ultraviolet and aggressive substances, but less durable, so it is connected in layers.

- LPVD low pressure has similar characteristics, but the material itself is strong, resistant to shock loads and compression. Similar technologies are used for the production of household containers that are able to withstand low and medium pressure.

Linear PE grades practically do not decompose in the environment, therefore, packaging products are subject to special disposal so as not to violate the environment.

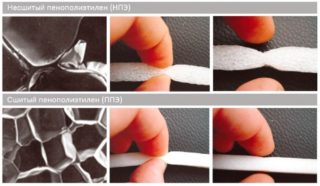

In addition to the types described above, there are special materials that are used in construction. It is cross-linked and non-cross-linked polyethylene.

Stitched

Crosslinking is a technology that increases the strength characteristics of polyethylene, the formula of which is CH2. During a chemical reaction, molecules form a three-dimensional cellular network, since hydrogen leaves them, and carbon is combined with each other. There is a concept - the degree of stitching. This is the ratio of cross-linked molecules and their total number.

There are three ways to sew PE:

- Physical. During the stitching process, the starting material is exposed to X-rays. The method is unreliable, since the products have an uneven degree of crosslinking due to poor penetration of rays throughout the entire thickness. Also, products of the PEX-C brand are not able to return to their previous shape when deformed. At low temperatures, products crack.

- Chemical, which is carried out using nitrogen (PEX-D) and silane (PEX-B) radicals. The method also did not become widespread due to imperfections in the products. The degree of crosslinking is 65%, which is very low.

- Peroxide method (PEX-A). Hydrogen peroxide is used at high temperatures. Allows to obtain the maximum possible degree of crosslinking - 85%.

Products obtained by peroxide melting are more expensive, but they can withstand heating up to 120 degrees. The tensile index also increases, XLPE pipes become more plastic, have shape memory.

Ultra-high molecular weight PE

Material with exceptional properties for use in extreme conditions:

- high frost resistance;

- corrosion resistance;

- abrasion resistance;

- low coefficient of friction;

- impact resistance;

- inertness to chemicals.

Ultra-high molecular weight PE is used for the manufacture of armored products, parts for mining equipment, filters, linings for sports equipment. The basis is high tenacity yarns obtained at low pressure.

Chlorosulfonated polyethylene (CPS)

Sulfurous anhydride and chlorine additives make it possible to obtain rubber-like PE, which has increased heat-resistant properties, as well as resistance to external environmental influences. Used by:

- for the production of adhesives and sealants;

- for the production of wear-resistant floor coverings;

- in the production of paints for concrete and metal.

The material is soluble in acetic acid and chlorinated hydrocarbon.

Foil polyethylene and its properties

Reflective PE is used in the construction of underfloor heating, as well as for noise insulation of ventilation shafts, pipelines, expansion tanks. The material is impermeable to steam and water. Consists of two layers - foamed polyethylene and aluminum foil, sanded to a degree of reflection of 97%.

Advantages of foil-clad PE:

- There is a certificate of complete safety of the material.

- It is not damaged by rodents, as it is inedible.

- Convenient for transportation.

- Fire safety. In domestic conditions, it is impossible to reach high temperatures at which the PE ignites.

- Insulates heat and sound at the same time. In this case, it is laid in a thin layer.

- A 4 mm layer can replace 8 cm thick mineral wool.

To install foil-clad polyethylene, there is no need to use a vapor-permeable film, since the material itself conducts water molecules well. Compared to mineral wool, it is worse, but condensation does not accumulate.

Disadvantages:

- PE with foil is very soft, therefore it is not used under plaster and wallpaper.

- For wall mounting, adhesive materials are used, since it is impossible to attach foil-clad polyethylene in another way. The use of nails impairs the thermal insulation properties.

For insulation of external walls, PE with foil is used as additional protection against moisture and to reflect heat into the walls.

There are several types of foil insulation:

- Marking A is PE covered with aluminum foil on one side.

- В - covering on both sides. It is used for interfloor ceilings as a separate insulation.

- C - one side is foil, the other is covered with an adhesive for ease of installation.

- ALP - Foil and laminated film on one side, uncoated on the other side.

- Marking M and R - corrugated PE covered with foil on one side.

Only polyethylene has thermal insulation properties. If it is used for laying under concrete, the aluminum interlayer does not fulfill its function, as there is no radiant heat.

The use of foil-clad PE in rooms with short-wave infrared floor heating is possible for the accumulation of rays and burns of the skin and retina. This property does not apply to long-wave infrared heaters.

Insulation technology

Heat can be discharged in the following ways:

- across the floor;

- attic, if it is unheated;

- cracks in windows or doors, if they are old wooden;

- through walls if there are hidden cracks in them.

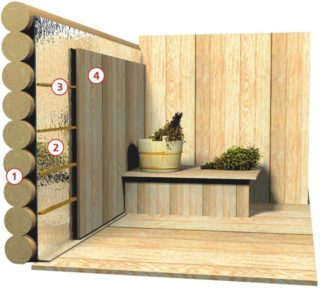

You can start insulating the room from the inner walls in order to quickly heat up an apartment or house.

To insulate the interior walls, it is better to use foil-clad VPE on one side. You can mount on the wall self-adhesive roll materials or use a construction stapler.

Work order:

- Spread the roll on the floor and cut to the desired length along the height of the walls.

- Using a ladder, attach the top edge of the material to the wall.

- Further, straightening the PE from top to bottom, attach it with small nails with wide caps or a stapler. It is important that the foam insulation fits snugly against the wall.

The second piece of polyethylene foam is applied end-to-end so that there are no empty spaces between the two sheets. After fixing all the joints are connected with aluminum tape to eliminate heat loss.

To insulate windows and entrance doors, foamed polyethylene bundles can be used, which are sold in different diameters depending on the width of the slots.The material can have an adhesive surface on one side, so the place is first treated with alcohol for degreasing, then PE is attached. According to its characteristics, the new material is better than traditional foam rubber, which turns yellow over time and crumbles under the influence of heat.

For laying under a screed, it is not recommended to use Penofol foil material for the following reasons:

- PE is thin and easily crumpled under the weight of concrete, so the thermal conductivity characteristics are reduced to a minimum.

- After a month of operation, nothing remains of the foil; in addition, it does not work in the absence of IR radiation under a layer of concrete.

- A floating thin screed, which does not adhere to the base due to the PE layer, begins to crack due to shrinkage, and with it the tile.

For laying under a concrete screed, a special multi-foil with a large mesh size is used, which does not deform under the weight of concrete.

How can you glue together

In the process of laying polyethylene foam, it may be necessary to glue the sheets to each other or to another material. Can be used:

- For VPE connection - Contact Acrol, Quick-Bond, Neoprene 2136, 88 NP.

- To glue the foam to another material or to glue the foam sheets together - Aqualit SK-106P, Polimin P-20, Master Super, Ceresit or Anserglob.

- To connect the VPE with the wall, it must be cleaned, treated with an antiseptic, dried, then use Nairit-1, Foamolon-2, 88 Lux or 88-Metal glue.

Before starting work, you need to think over your actions and provide for what adhesives may be needed in the process.

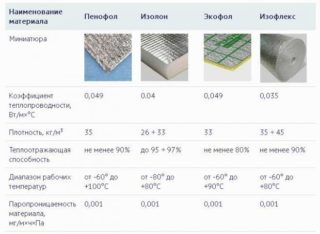

Main brands

Penofol is the most popular material that can be bought at a construction supermarket. It is sold in rolls of 15 - 30 m, 60 cm wide and 3 - 4 mm thick. Penofol qualitatively connects the layers to each other by the hot-soldering method - foil and foamed polyethylene, so there are no problems with operation.

Quick Step is a domestic company that bought a license from a European manufacturer and produces insulation made of expanded polyethylene, including for pipes of different diameters.

Germaflex

Produces PE of various grades, assuming different temperature effects during operation. You can choose the material with optimal performance for a long service life.

Vilatherm

The Vilatherm brand produces polyethylene foam bundles of various diameters, which are used to insulate windows and doors. The company does not produce rolled sheet varieties.