Building and decorating your own home is a costly undertaking. The service life of the building and comfort depend on the quality of the purchased building materials and compliance with the installation technology. Getting started with thermal insulation of walls, it is recommended to pay attention to hard mineral wool boards from the European manufacturer Rockwool.

Specifications

Rigid mineral wool slabs are manufactured by the Danish company Rockwool, which specializes in the design and manufacture of high quality building materials. The advantage of this mineral wool is its versatility, it is used when installing the latest thermal insulation systems.

Main technical characteristics of high-strength rigid mineral wool boards:

- the size range is large, the most common is 1000 * 600 * 50 mm;

- the thermal conductivity index ranges from 0.035-0.041 W / m * K - the indicator changes depending on the air temperature;

- the density reaches 90-100 kg / m3, in the lightweight model "N" - 37 kg / m3;

- vapor permeability degree 0.30 mg / m;

- water absorption indicators - 1.5%.

The acidity modulus reaches 2 units, thanks to which mineral wool is able to withstand aggressive environmental factors. The pull-off force of the slab is 3-4 kPa, and the tensile strength is 10 kPa.

All model lines of Rockwool heaters belong to the NG flammability group.

Insulation models

Stone wool is presented in four modifications. The technical specifications are slightly different.

Standard

Thermal insulation boards of the Standard category are used as insulation in curtain wall systems. The option is universal in its use. The material has high strength and resistance to aggressive external influences.

Optima

Rockwool Venti Butts Optima has almost the same technical characteristics as its predecessor Standard, but even more versatile in its use. The building material is allowed to be mounted in the presence of a light-transmitting cladding. It is also recommended to purchase such plates for filling fire boxes near window openings.

Butts D

Insulation Venti Bats D is a two-layer combined structure. The upper (outer) layer has increased density and rigidity, while the lower (inner) layer is lighter. In comparison with analogs, this modification is more expensive. To simplify the installation procedure, the top layer is marked.

Butts N

Insulation Rockwool Venti Butts N is a lightweight board that is used as an inner layer of two-layer thermal insulation in hinged facade systems.

The characteristic features of the material are low density and weight (in comparison with other modifications, 3 times less), which reduces the load on the foundation of the structure. The minimum board thickness is 50 mm. The excellent thermal insulation properties are evidenced by the thermal conductivity coefficient equal to 0.036 W / m * K.

Advantages and disadvantages of Rockwool Venti Butts heaters

Numerous consumer reviews indicate that the building materials of the Danish company are practically devoid of flaws.The most significant disadvantage is the high cost of hard mineral wool boards. But this disadvantage is compensated by the high quality of materials, which are simply ideal for the installation of hinged ventilated facades.

The main advantages of the stone wool model line:

- Due to the fibrous-porous structure, the insulation is a permeable raw material, which prevents the accumulation of pathogenic microflora (mold and mildew) under the coating during operation. Manufacturers claim that the minimum service life of building materials reaches 50 years.

- Economical and easy to install thanks to the use of a special fixing adhesive. The material is hard, but it is conveniently cut into fragments of the required size. This allows joints and corners to be perfectly formed.

- The material is moisture resistant, has excellent heat and sound absorbing properties.

- If the walls are insulated with such plates, they are not deprived of the ability to "breathe". This property is especially valuable when decorating wooden houses. The material does not burn, but only melts after the ambient temperature exceeds 1000 degrees.

The most important feature is that the building material does not adversely affect human and animal health. Basalt fibers are environmentally friendly. The stone fibers used in the production are less fragile in comparison with glass wool, therefore dust and pathogenic microflora do not accumulate in their cavities.

Features of installation of heaters

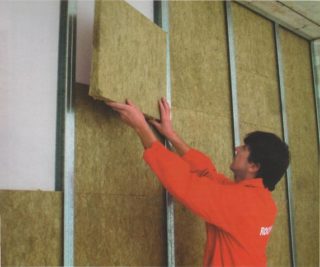

The facing part of the slabs is fixed on special fasteners drilled into the wall, and not on mineral wool with a reinforced plaster base.

Thanks to this technology, a small blown gap is formed between the cladding and the insulation.

When using Rockwool mineral boards, there is no need to additionally treat their surface with a windproof film.

Stages of work:

- Prepare all the necessary work equipment, the base of the surface.

- Mark the places where the fasteners for the facade will be fixed, provided that it is assembled on a special frame.

- All fasteners are installed.

- Slabs are installed on the wall using a special mortar.

- The installation of mineral wool continues until the wall is completely hidden under it.

- After the solution has solidified, it is imperative to fix the insulation again with the help of disc dowels.

- If necessary, installation of waterproofing is carried out.

- The second level facade frame is being assembled.

- Finally, the cladding elements are installed.

If the task is to assemble a single-layer standard facade, the list of works is even smaller. It is enough to carry out finishing work on the slabs. They are plastered, cladding is applied on top.

It is possible to combine the assembly of the ventilation facade and the frame. The method is used when ventilation is an additional useful factor. They start work with the assembly of the frame from metal profiles. Plates are installed and fixed on them. The frame details should be assembled so that they protrude 3-5 cm above the slabs. As a result, a natural gap will form, which will play the role of the facade ventilation system.

Scope of insulation

Heaters are used in the following cases:

- in the role of the base of floors and pitched roofs;

- in sea vessels, building structures, industrial equipment, pipelines and air lines;

- in saunas and baths;

- for insulating thin walls and balconies.

To purchase high-quality building materials, it is recommended to ask a consultant to provide certificates before buying.