The range of thermal insulation products is increasing every year. Manufacturers create new materials and improve the properties of old ones, resulting in a high-quality insulation with a comfortable shape and performance. PIR plates are among the new heat insulators.

Chemical structure of the material

The insulation has the full name polyisocyanurate. It is similar in its properties to polyurethane foam, the differences lie in the proportions of the starting substances and the use of catalytic additives in the synthesis. Also, production takes place at a different temperature regime. The output is a complex polymer with a ring molecular structure. Compared to polyurethane foam, PIR has an increased resistance to heat transfer, chemical inertness and mechanical strength.

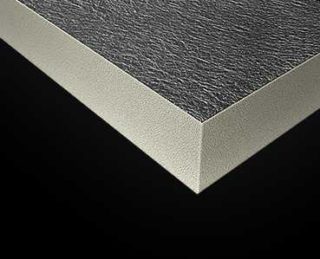

The insulation has a porous structure with a closed cell filled with gas. High thermal insulation properties are provided due to 5% polymer content and 95% gas filling. The polymer has high adhesion to various surfaces. This leads to difficulties during installation due to the stickiness of the material to all objects. For this reason, the boards are always covered on both sides with a protective layer, which also increases resistance to mechanical stress, UV rays and natural factors.

Varieties of heaters

PIR boards differ in filler material and thickness. The purpose of the insulation depends on these indicators.

There are the following types of coatings:

- Kraft paper. Used for insulation inside the building. It is an excellent base for subsequent finishing.

- Fiberglass for covers. Also used for interior decoration and exterior wall insulation. The top may have a mineral coating.

- Fiberglass and bitumen impregnation. Used in roof insulation.

- Aluminum. It can be multi-layered, smooth, with kraft paper. The reflective surface improves thermal insulation properties.

- Fiberglass with graphite components. Allows to increase the resistance to open fire, thereby improving the fire resistance of the entire structure.

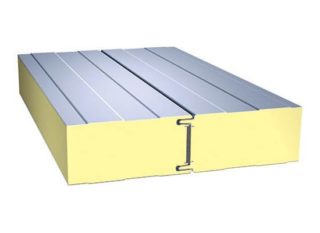

- Sandwich panels with polyisocyanurate foam. They can perform bearing and insulating functions at the same time. They are actively used in industrial construction.

PIR boards are available in various sizes. The thickness should be minimal, since the material is expensive, and even a thin layer is able to insulate the structure with high quality.

Plates are produced with flat ends and a locking part. Thanks to the presence of the lock, you can make a seamless coating through which cold will not penetrate.

Main characteristics

PIR insulation is considered one of the best heat insulators. This is made possible by its characteristics.

- The thermal conductivity coefficient reaches 0.021 W / m * K. In real conditions, it can be slightly higher, in the range of 0.024-0.027 W / m × K, but its insulating properties do not become worse from this.

- Hygroscopic and vapor permeable. The rigid closed cells of the structure do not allow water to pass through. Experiments show that moisture is incapable of affecting the quality of the material. The vapor permeability coefficient is 0.0015-0.015 mg / m * h * Pa.

- Medium density due to the porosity of the structure. It fluctuates in the range of 20-50 kg / m3. It is convenient to work with the material, it retains its shape well during the entire service life. Does not shrink and withstands multiple compressive loads without severe loss of shape and strength. For additional strength, the plates are treated with other materials.

- Fire resistance. When exposed to an open flame, the top layer is charred. Melting, fire spreading and fluidity do not occur. The lining also affects the flammability group - plates with foil belong to the G1 class, with G2 craft paper. At temperatures above 200 ° C, the material begins to crumble and lose its strength. Does not emit harmful toxic substances that can harm human health and the environment.

The properties of the pir insulation may vary slightly depending on the selected lining material.

Advantages of a heat insulator

All physical, operational and technical characteristics of PIR plates can be attributed to advantages. There are other positive qualities:

- Durability. The manufacturer claims that the service life of the pir thermal insulation can be 30 years or more.

- Wide range of permissible operating temperatures.

- The material is not subject to decay, has a high chemical resistance to aggressive compounds.

- Fungus and other parasites do not start in the slabs, it is not suitable for creating nests for birds and is not interesting for rodents.

- Environmental friendliness. Due to its chemical stability, the insulation does not emit pollutants into the atmosphere.

- During installation, the plates do not generate dust and do not harm human skin. The master may not use personal respiratory and eye protection during installation work.

The material also has drawbacks due to which it is not widely distributed.

- Lack of information. Few home owners know about such insulation.

- High price. It is associated with a complex technology of manufacturing a heat insulator.

All these shortcomings will be eliminated over time, and PIR insulation will be actively used in installation and construction work.

Manufacturers

Russian companies are actively developing in the production of PIR panels. They offer a wide range of quality products in different sizes and cover materials. The most popular manufacturers include the following Russian brands:

- PirroGroup. The company has its head office in Moscow and production in Saratov. It produces one of the standard quality insulation based on polyisocyanurate foam, which is the main specialization. Offers pir insulation boards with a thickness of 20 to 200 mm in 10 mm increments. Any cover options are available.

- Profholod. Initially, the company was engaged in the production of sandwich panels with polyurethane foam, but later their activities expanded. Since 2014, they have been producing PIR panels of various types. Now on sale 8 types of material are supplied, which are also divided by thickness.

- Feast insulation Technonikol, which produces the LOGICPIR line. It presents different types of slabs for all areas of application in professional and individual construction. There are narrowly focused varieties, which are named according to the place of application - "wall", "balcony", "floor". Insulation pir Technonikol is considered one of the most famous due to the popularity of the brand.

Due to the high cost of the plates, you need to carefully calculate all the necessary characteristics, dimensions and thicknesses so as not to buy an unsuitable insulation by mistake.

Any building structure must, in total, have such a resistance to heat transfer that it is within the framework of the norms established by SNiP. These values depend on many factors - the region of residence, the purpose of the building, the place of construction.

Installation features

All types of heaters feast have their own styling and fastening methods. The material on the walls is traditionally taken with dimensions of 0.6 * 1.2 meters. The thickness depends on the area where the insulation is created. Laying is carried out end-to-end with interlocking fastening of plates to each other. The material is attached to the base on dowels, having previously applied the base to the surface of the adhesives.

Sandwich panels are also connected to each other with locks and blown out with polyurethane foam for tightness. Additionally, the attachment points can be treated with glue. The slabs are fixed to the frame with sheet steel bolts.

Roofing insulation is similar to a sandwich structure, but only one side is sheathed with a sheet. The structure is airtight when laid due to the shape of waves that overlap.

The thermal insulation for the ceilings has a locking mechanism on all sides. No additional fasteners required.