Reducing heat losses is a major challenge when planning district heating. For this, even at the stage of heating the coolant, special conditions are created for its transportation: increased pressure, maximum temperature regime. But in order for the heating level to decrease to the required level during the distribution of hot water, an elevator heating unit is installed: schemes, operating principles and checks must strictly comply with the standards. Even though it is part of a central heating system, the average user should know how it works.

Purpose of the elevator unit

Even at the first stages of central heating design, engineers faced the problem of conserving thermal energy due to the length of heating mains. To reduce heat loss, two main methods are used:

- Maximum thermal insulation of the pipe surface;

- Installation of elevator units in buildings.

The operating temperature in the outer heating pipes is 150 or 130 degrees. It is forbidden to supply water to consumers at this temperature. That is why an adjustable elevator heating unit was developed. It is designed for mixing hot and cold heat carrier streams in order to optimize its temperature. In addition, the pressure is also reduced to an acceptable level.

For normal operation, an automatic elevator heating unit is installed in a pre-prepared room. For residential apartment buildings, this is the basement. Installation and further maintenance should only be carried out by specialists. Any violation of the operating mode can lead to emergency situations. Installation of such a heating element in private houses is impractical. This is due to the fact that the boilers will not be able to provide the proper temperature mode of operation. Therefore, it is used only to create branched heating systems with a large length of external heat pipelines.

Taking the principle of operation of this elevator heating unit as a basis, it is possible to make a similar system for an autonomous system. But for this, two or three-way valves with thermostats are used.

The scheme of the elevator unit

At first glance, the principle of operation of the elevator unit of the heating system should be a rather complex system. However, in practice, a successful design has been developed, which in its technical characteristics is similar to a three-way mixing valve.

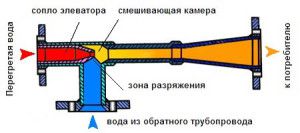

Structurally, it consists of the following elements:

- Inlet pipe... A heat carrier with a high temperature under maximum pressure enters through it;

- Return connection... It is necessary to connect cooled water for further mixing with a stream of hot;

- Nozzle... The key element of the diagram of the elevator nodes of the heating system. Hot water enters it under pressure and creates a vacuum in the receiving chamber. As a result, the cooled coolant mixes with the heated one;

- Outlet connection... It is connected to a distribution pipeline system for further transportation of liquid to consumers.

In addition to it, the elevator unit of the central heating system must include additional elements.These include mud collectors, valves and sensors. The latter are mandatory for installation, since they are used to control the parameters of the entire system.

Having figured out what an elevator heating unit is, you need to learn more about its types and methods of adjusting operating modes.

After checking the operation of the elevator unit and the entire heating system, it is imperative to require an updated passport for the device. It indicates the initial characteristics and the actual after verification verifications.

Types of elevator heating units

This heating circuit of the elevator unit does not disclose the mechanism for adjusting the temperature regime. And this is the main way to optimize the consumption of thermal energy, depending on external factors - the temperature outside, the degree of thermal insulation of the house, and so on. For this, a special tapered rod is installed in the nozzle. Gear drives ensure its connection to the valve. By adjusting the position of the rod, the throughput of the nozzle changes.

Depending on the installed equipment, there are two types of adjustable elevator heating units:

- Manual way... The valve is rotated using the traditional method. In this case, the responsible employee must monitor the readings of the manometers and thermometers of the system;

- Auto... A servo drive is installed on the valve pin, which is connected to temperature and pressure sensors. Depending on the set parameters, the movements of the rod are performed.

A typical drawing of an elevator unit should include not only the required elements, the operational characteristics of the system. And for this you need to make a calculation of the parameters. Such work is carried out only by specialized design organizations, since it requires taking into account all factors.

Installation of an adjustable elevator unit for heating in combination with a heat energy consumption meter will save up to 30% of the consumption of hot heat carrier.

Features of installation and verification

It should be noted right away that the installation and verification of the operation of the elevator unit and the heating system is the prerogative of the representatives of the service company. The residents of the house are strictly prohibited from doing this. However, knowledge of the layout of the elevator units of the central heating system is recommended.

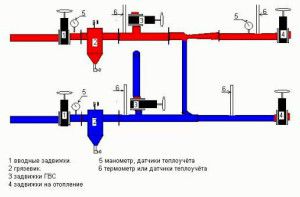

During design and installation, the characteristics of the incoming heat carrier are taken into account. The branching of the network in the house, the number of heating devices and the temperature regime of operation are also taken into account. Any automatic elevator unit for heating consists of two parts.

- Adjusting the flow rate of incoming hot water, as well as measuring its technical indicators - temperature and pressure;

- Directly the mixing unit itself.

The main characteristic is the mixing ratio. This is the ratio of the volumes of hot and cold water. This parameter is the result of accurate calculations. It cannot be constant, since it depends on external factors. Installation should be carried out strictly according to the scheme of the elevator unit of the heating system. After that, fine tuning is done. Maximum load is recommended to reduce error. Thus, the water temperature in the return pipe will be minimal. This is a prerequisite for precise control of the automatic gate valve.

After a certain period of time, scheduled checks of the operation of the elevator unit and the heating system as a whole are required. The exact procedure depends on the specific scheme. However, you can draw up a general plan, which includes the following mandatory procedures:

- Checking the integrity of pipes, valves and devices, as well as the compliance of their parameters with the passport data;

- Alignment of temperature and pressure sensors;

- Determination of pressure losses during the passage of the coolant through the nozzle;

- Calculation of the displacement coefficient. Even for the most accurate heating scheme of the elevator unit, equipment and pipelines wear out over time. This correction must be taken into account when setting.

After completing these works, the automatic elevator central heating unit must be sealed to prevent unauthorized interference.

Do not use homemade elevator node schemes for central heating systems. They often do not take into account the most important characteristics, which can not only reduce the efficiency of work, but also cause an emergency.

Requirements for the premises

In the vast majority of cases, mixing units are installed in the basement of a building. To perform its functions, it is necessary to take into account the characteristics of the room - seasonal changes in temperature and humidity.

There are a number of requirements for these indicators, which must be met. In particular, this applies to elevator units of the central heating system with installed automatic servo drives:

- The room temperature should not fall below 0 ° С;

- To prevent the appearance of condensation on the surface of the pipes, an exhaust ventilation system is installed;

- For electrical appliances, a separate switchboard must be installed. It is recommended to provide an autonomous power supply in case of an emergency power outage.

However, in fact, it is rare to find that these rules are followed. As a result, even for the most efficient drawing of an elevator unit, its practical implementation may differ significantly. That is why alternative schemes have appeared for mixing coolant flows.

Some new apartment buildings connected to central heating do not have an elevator heating circuit. To install it, you need to contact the management company.

Other options for heating units

Based on the basic principle of operation of the elevator unit of the heating system, alternative ways of maintaining the desired temperature level in the pipes for users have been developed. Their difference from the traditional scheme lies in the presence of a complex electronic control system.

The first thing that the developers of this unit paid attention to was the optimal consumption of hot water. Therefore, a heat energy meter is necessarily installed on the inlet pipe. It makes it possible not only to see the volume of the coolant entering the system of the house, but also can automatically calculate its cost and transfer data to the management company.

The installed pumps allow you to control the rate of passage of the coolant through the pipes. This is necessary to reduce the error when mixing fluid flows in the nozzle. For this, temperature sensors are mounted on the inlet and return pipes. If the water heating level is less than the set one, the pump on the return stops working. To increase the volume of the hot coolant, the corresponding pumping equipment is activated.

However, one must also take into account the disadvantages of such a system:

- Dependence on power supply. The emergency source of electricity can only work for a short time. For overvoltage protection, a condensation rectifier must be installed;

- As the complexity of the system increases, the likelihood of its failure increases. It is enough for one of the sensors to fail - the parameters of optimal mixing will change.

Despite these factors, the popularity of the new systems is due to their ease of use and significant savings in heating costs. That is why improved elevator units for the central heating system will be in demand.

As for the primary costs for the purchase of equipment and installation, these investments are returned in the form of savings on heating costs within 3-5 years. But on condition that professional and honest companies are engaged in the design and installation.

An example of the integration of an elevator heating unit in conjunction with a heat meter: