Abro sealant has long and firmly established itself in the automotive consumables market. It is versatile in use, reliable, resistant to temperature effects. It is important to study the assortment in order to use the sealants correctly and for their intended purpose.

What is Abro sealant

The acquisition of the working properties of silicone compounds occurs due to the moisture present in the air.

The composition includes:

- dimethylsiloxane;

- silicon;

- kerosene;

- methyltriacetoxysilane;

- vinegar;

- other additives that give the product the desired properties.

- Gasket maker - full-fledged gaskets former. The sealant can replace silicone, paper felt seals other than those used to seal cylinder heads.

- Gasket sealer, such products cannot replace gaskets, serve only to level surfaces, fill pores in mating parts and improve adhesion.

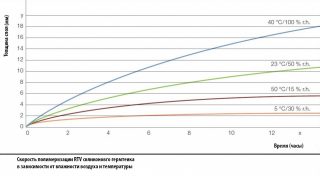

- RTV silicone - a sealant, the complete polymerization of which occurs at room temperature in an environment of water vapor. The speed of a set of operating parameters depends only on the thickness of the layer.

- Sensor safe - the products are safe for oxygen lambda sensors; sensors made of non-ferrous metals can be mounted on it.

- Hi-Temp - the product can withstand particularly high temperatures up to 370 ° С, while formulations without such marking work up to 260 ° С.

- Valve cover can be used to seal valve covers where corrosive oils are exposed at elevated temperatures.

Other designations add specifics to the descriptions, help to understand the meaning of what is written in the operating instructions and are not so important for users.

Varieties and scopes

The manufacturer himself carries out the main classification based on what substance is released during polymerization.

Acid sealants have a vinegar smell. The material is widespread due to its versatility in the construction and repair of machine units, this type of product quickly polymerizes.

Acetic acid can degrade non-ferrous metal parts, which limits use.

Neutral remedies practically odorless, have excellent adhesion even to dirty surfaces, do not cause reactions with copper and aluminum.

The color of the packaging and of the silicone is for easy identification of the type of sealant. For rare use, it is important to read the instructions.

The manufacturer points out that red, white, transparent versions do not have an artificially introduced pigment in the composition and have high shear and tear strength.

- The black "Works" in the temperature range from minus 40 to 260 ° С, it is used to improve the tightness of standard felt, paper and rubber gaskets and to form seals for thermostats, pumps, and other parts made of ferrous metals. During operation, the composition is resistant to vibrations.

- Blue, acidic type of hardening. Used at the same temperatures as ferrous and also suitable for non-ferrous metals.There is a limitation - not suitable for sealing air sensors, as it releases acetic acid.

- Transparent used to create gaskets up to 6 mm thick, operating at temperatures up to 260 ° C. Not destroyed by oils, transmission fluids and antifreeze. In everyday life, it replaces sanitary products for seams.

- Red the composition is stable up to 343 ° С and stands out for its high peel strength. High temperature resistance allows this type to be used for valve cover gaskets, transmission parts, intake manifolds, engine pallets and automatic transmissions.

- Grey the variant completely replaces the gaskets, i.e. parts are joined directly. It can be used for sealing paper, felt and rubber gaskets. Safe for any metals, applicable to any assemblies and parts, with the exception of engine exhaust manifolds.

- Abro High Temperature Sealant looks like solidified copper, but in fact there is no metal in it. Does not interact with metals, withstands heating up to 370 ° C, resistant to loads, approved for sealing lambda sensors. It is used for any units except the exhaust manifold.

- White the sealant is efficient up to 260 ° C, resistant to oils, water, vapors of the cooling system, technical fluids, except gasoline. These properties make the white type of sealant versatile.

The manufacturer categorically does not recommend Abro sealant for use in places of direct contact with gasoline, for example, for sealing fuel lines, tanks, pumps.

How to use a sealant

- Use a scraper to clean the mating surfaces from the remnants of old gaskets.

- Degrease the contact points with gasoline or cleaning fluids.

- The composition is applied with a layer of the required thickness. The composition is squeezed out of a metal tube. Products packed in tubes are applied with a pistol. For ease of dosing, a tip is used, the spout of which is trimmed to the required level.

- Withstand parts for about 10 minutes or according to the recommendations on the package.

- Articulates parts, eliminating full tightening of bolts or nuts.

- The full polymerization time is indicated on the package, approximate figures can be found in the table for sealants of different colors from the manufacturer's website.

For reliability, experienced makers recommend leaving the parts for a period of 24 hours, during which time a layer of any thickness is guaranteed to polymerize.

Security measures:

- work with acidic compounds in a ventilated area;

- use protective gloves, respirator, goggles;

- wash off the product with warm running water if it comes into contact with open skin or mucous membranes, if irritation persists, consult a doctor;

- store products out of the reach of children and pets.