Acrylic putty is a modern and environmentally friendly material for preparing ceilings and walls for finishing. Compatibility with different types of paints and varnishes and resistance to environmental factors make it a popular composition for facade work and indoor repairs.

Description and material properties

Wall treatment with putty is carried out for sealing small cracks in the wall and defects damaged plaster, final finishing for painting to give the surface evenness. The acrylic composition adheres well to various substrates, dries quickly, and tolerates temperature changes well.

Composition and characteristics

it moisture resistant composition based on liquid acrylicwith good environmental safety indicators, with chalk and talcum additives. The ready-to-use product has paste consistency.

Putties are easily applied with a simple spatula or spray gun (the second option is used when the mixture is very thin). Sanding the surface is also not a problem: sandpaper is suitable for this.

Scope of application

The formulations are used to treat a wide variety of premises and materials. Interior acrylic putty is designed for only for rooms with dry air... Moreover, it is compatible with different types of bases.

For pretreatment of the bathroom or any other damp room you need an acrylic putty for outdoor use. It is also suitable for facade decoration.

There are also universal formulationsthat can be used both indoors and outdoors.

Putty on acrylic can be used with different reasons - with concrete or brick, wood, plasterboard, plastered surfaces. Wherein for concrete, it is better to choose a water-dispersion mix variant. It will prevent moisture from cracking the material. But such a product is only suitable for wall surfaces.

Varieties of acrylic putties

Acrylic putty goes on sale in two forms: in a ready-to-use form and in powder.

Ready option good because the master does not have to waste time kneading. Moreover, there is no risk of non-observance of proportions or cooking technology, so you can be sure that the specified characteristics of the product will be preserved.

A plus mixtures in powder - profitability, but it should be used if you have experience in the independent preparation of mortars. The nuances of this work are always given in the instructions on the package.

On the market there are starting and finishing compounds for filling.

Starting are used for the primary leveling of wall planes, elimination of height differences, large cracks and other clearly noticeable defects. These products have a coarse texture.

Finishing mixtures are applied under a decorative coating.

For wooden surfaces produce a special type of acrylic putty containing fungicidal and antiseptic additives that prevent rotting and parasite damage.

Instructions for use

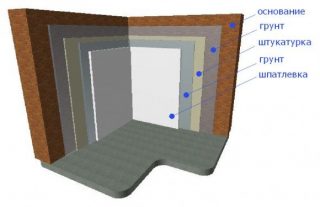

The primer composition for applying putty is also selected on the basis of acrylic. Better if these are two products from the same manufacturer.

Consumption

Consumption of the composition depends on the thickness of the applied layer... For a thin coating of 0.1 cm, it will be 1.2 kg per square meter. For thicker thicknesses, the consumption will increase (up to about 1.6 kg).

When buying a composition, you need to take into account roughness of the plane (the presence and size of cracks, etc.) and purchase it in the amount necessary for the successful elimination of defects.

Required tools and materials

To complete the work you will need:

- respirator and goggles to protect against dust ingress when sanding walls;

- emery cloth, if necessary - a sander;

- alignment control tool (usually a level);

- priming brushes and rollers;

- stirrup ladder;

- a set of spatulas of different sizes (including for processing corners and adjacent parts);

- painting net.

Mix and surface preparation

Walls need clean from dust and dirt... If there are remnants of the old finish on them, it is better to remove them. Sometimes craftsmen widen large gaps so that they are completely filled with mortar.

Apply to a clean, dry surface acrylic primer according to the technology described in the instructions. For this, a roller or a large brush can be used.

Putty in polymer containers does not need special preparation. If a dry compound is used, it knead just before applying in a small amount... Use this amount immediately after preparation. Subsequent doses are mixed as needed.

Application rules

Sequence of work:

- After complete drying of the soil on the walls apply starting putty and dried throughout the day - the duration is indicated for room temperature, for lower thermometer readings it will be longer.

- Surface sanded and primed again... After it dries, the starting composition is again applied and allowed to dry for a day. This sequence of actions is repeated until the desired evenness is achieved after the next grinding and priming.

- After the soil has dried, finishing coat... For painting, it must be processed with fine sandpaper. It is not necessary to do this under wallpaper with a textured surface.

Popular manufacturers

Another Russian brand of universal putty - "Lacra".

In Siberia make acrylic compounds produced under the brand Diola. Used for production foreign raw materials... The assortment also includes a waterproof elastic compound specially for wood. One of its advantages is tinting for different breeds. This wood putty can only be used indoors in dry rooms.

For leveling walls in dry rooms, the composition is suitable Parade S40. It is flexible, fills cracks well, and is easy to grind. It can be applied with a spatula in several layers of 0.1-0.2 cm, while the total thickness can reach 0.5 cm. Work should be carried out at temperatures above +12 degrees and humidity no more than 80%.