Ordinary drywall is not very effective at dampening sounds; when it is installed, additional insulation from noise is laid in the frame. They release a new type of material that better copes with the correction of the mid-frequency and low-frequency range - perforated acoustic drywall. During installation, the front surface remains visible, therefore, a mounting method is used that is slightly different from the standard one.

Features of acoustic drywall

Purpose of perforated g / cardboard sheets:

- reducing the sonorism of background sounds in the room;

- elimination of echoes in spacious halls of mansions;

- improving the hearing and perception of the conversation;

- reducing the boominess to nothing.

A special type of drywall is produced according to the principle of standard panels, but there are differences. They consist in perforation of the face layer and additional non-woven layer on the other side.

Product characteristics:

- panel length - 2000 - 2500 mm;

- width - 1200 - 1500 mm, standard thickness 12.5 mm;

- the weight is determined by the dimensions of the plates, the square weighs 8.4 - 9.8 kg;

- gypsum density in the range 650 - 750 kg / m3;

- sound absorption coefficient - 0.95;

- panels are slightly flammable (group G1), resistant to aggressive conditions.

Application area

Material sheets reduce echo in large halls... They are installed so that a continuous coating without seams is created on the surface of the walls and ceiling, damping noise due to the holes. A layer of g / cardboard is sometimes mounted together with acoustic mineral wool.

Material use cases:

- concert halls, television recording studios, cinemas;

- residential buildings with private cinemas;

- conference rooms, speech booths;

- trade pavilions, large supermarket halls;

- waiting rooms at railway stations, airports;

- coworking offices, long corridors;

- subway stations, churches, cathedrals;

- technical rooms such as elevator engine rooms, ventilation chambers, boiler rooms and pumping stations.

Soundproof acoustic GVL can be compared with sound-absorbing g / cardboard. The material contains cellulose fibers, which also help absorb sound and correct the wavelength range. Additionally, the sheets are shockproof, therefore they combine several qualities.

Varieties of soundproof drywall

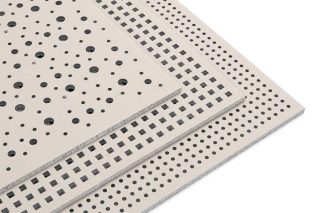

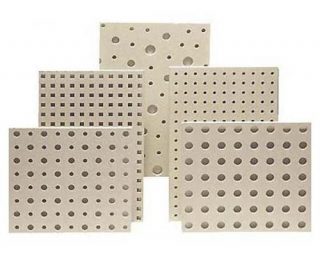

Perforated hole types:

- round - the diameter of the punctures is up to 8 mm;

- scattered round - make holes from 8 to 20 mm in size;

- square - they are made with a cross section of 12 mm.

The variety of punctures and their location on the panel affect the appearance and quality of soundproof drywall. Plates are produced from different edges: straight and folded (PC and FC, respectively).

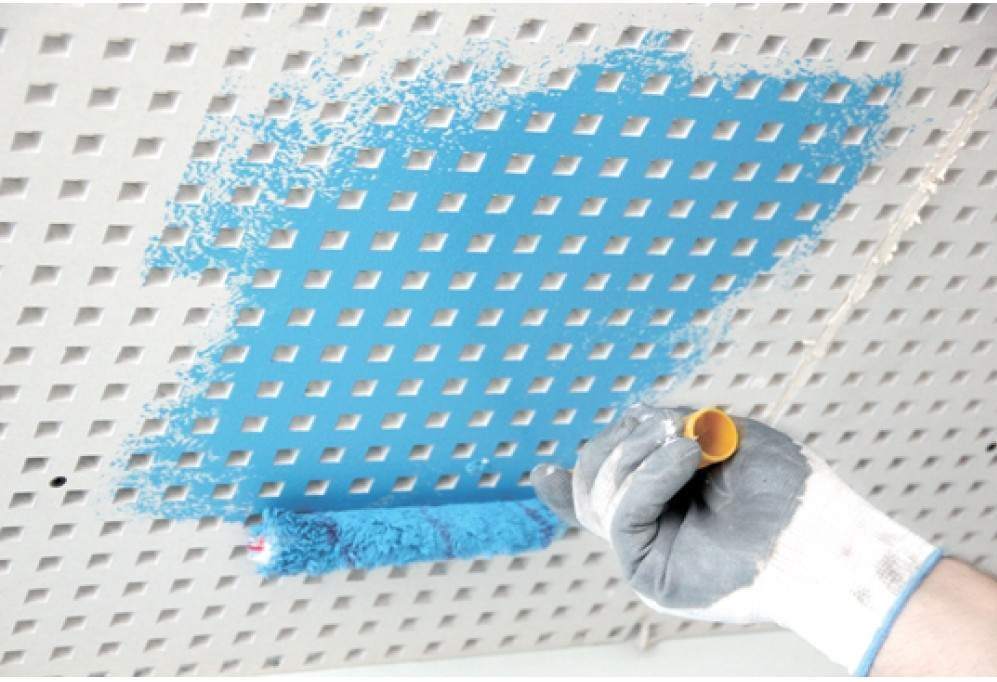

Installation features

Frame mounting technology is no different from installing the lathing under ordinary sheets of g / cardboard. The changes concern the fastening of the panels themselves. They are fixed with a hidden method, while the self-tapping screws are screwed into the perforation holes. Before that, special plastic plugs are placed in the punctures.

Installation rules:

- a material with the same characteristics and type of perforation is placed on one surface;

- the seams between the panels are putty without installing a reinforcing mesh;

- an assembly gap of 3 mm is left between the side edges of adjacent sheets, in order to subsequently seal it with a putty.

Plates of GKL "acoustic" with FC are not putty, because the sides are joined with the help of a curly edge. The sheets are placed so that the rows of perforations in adjacent sheets are on the same level.

Popular manufacturers of acoustic drywall

The second most popular material is Rigiton brands... Large-format sheets are mounted using a seamless method using a special durable putty. Products are used for installation in offices, medical facilities, sheets are produced with round and square perforations. Dimensions 3000 x 1200 x 12.5 mm.

They use products no less successfully Knauf brands... Produced with various perforation options, installed in concert halls, music centers, classrooms. Panel dimensions 2500 x 1500 x 12.5 mm. Products are resistant to temperature extremes and humidity.