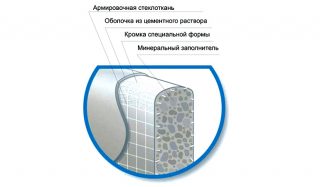

Aquapanel is a durable and lightweight slab for false ceilings and wall decoration. The material is used in warm rooms, it is also used in open gazebos, awnings, on facades. The internal and external Knauf rectangular aquapanel contains a mineral core, a Portland cement sheath. Fiberglass mesh is laid on both sides outside.

- Features of the use of water panels in construction

- Material characteristics

- Varieties of material

- The difference between panels for interior and exterior decoration

- Features of the installation of water panels on the example of Knauf products

- Ceiling installation

- Assembly of partitions

- Mounting methods

- Safety and Transport Regulations

Features of the use of water panels in construction

Material made on a conveyor, where a continuous strip of concrete of the required thickness is formed. The surface is coated with cement mortar liquid consistency and fiberglass mesh... The mass hardens, then it is divided into individual elements. The surface of the slabs is smooth off the face, but the reverse side is characterized by roughness... The products are obtained light gray.

- mineral layer plays a role insulation, provides rigidity to the product;

- fiberglass fabric prevents cracking when finishing arched structures, does not allow the front cement shell to crumble;

- the cement layer on the surface provides moisture resistant qualities of the panel, creates a surface that is impervious to water.

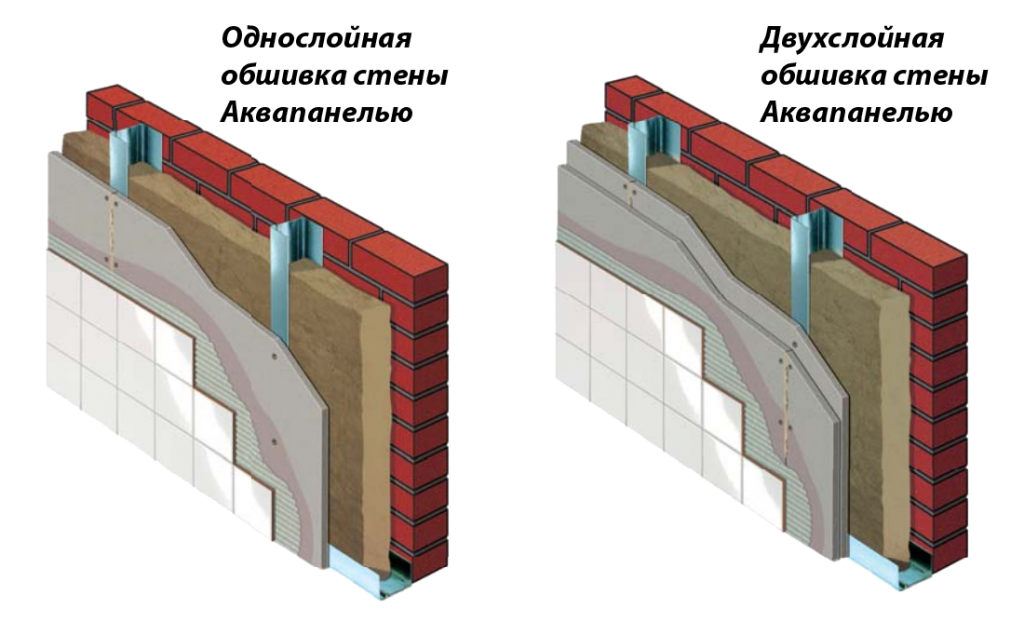

Sheathed sheets Not only ceilings, but also walls in wet rooms, for example, in saunas or swimming pools. Set the material like drywall on the frame made of galvanized metal profiles. Attached to the crate special self-tapping screws for such panels or fix adhesives.

Application area moisture resistant aquaplates:

- cladding of external walls of houses, plinths and pedestals of buildings;

- filling between elements of frame structures;

- for interior decoration of walls, ceilings, arched openings, vaults with a radius of curvature of more than 1 meter;

- sheathing of areas in engineering tunnels, mines;

- installation as an outer layer in fireplaces, stoves of various designs;

- installation of false walls, partitions, decoration of niches;

- surface treatment in garages, basements, storerooms, cellars;

- in the form of a base for soft tiles, roofing material;

- in the construction of car washes, service stations.

The material can withstand up to 75 courses of freezing and thawing, serves about fifty years old.

During installation, take into account the essential the severity of the finishing layer - the weight of each square is on average 10 - 15 kg.

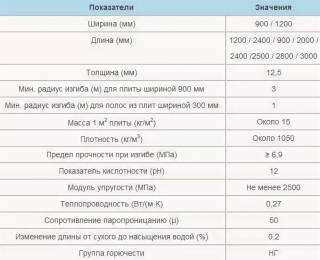

Material characteristics

Plates have almost unlimited uses, good performance... The external and internal water panel is used by architects in various finishes, curved concave and convex planes... Frame-type walls are several times lighter than those built of brick or concrete.

Product properties:

- composite components do not respond to high humidity, therefore, the sheets are placed in showers, public bathrooms;

- core, fiberglass and cement not valuable for bacteria, fungi and mold, rodents do not settle in the mass of the material;

- panels do not burn, they are classified as a fire-resistant class, they are installed in rooms with a fire hazard, while processing with fire retardants is not needed, flammability group G-1;

- after installation of water panels it turns out uniform surface without seams, which are closed up at the stage of finishing;

- density of products 1050 - 1350 kg / m³;

- vapor permeability plates provide an acceptable microclimate, additionally the coating protects against sounds;

- there are no active chemical ingredients in the raw materials, therefore the products are considered environmentally friendly;

- at temperature extremes in outdoor use material keeps stable parameters, it does not expand or contract from heat and cold, frost resistance - up to -50 ° С;

- after installation the plane of the panels can be finished with any kind of decorative materials - universal boards are perfectly combined with different types of topcoats;

- installation is carried out no wet processestherefore, work outside the building is carried out all year round.

Panel thickness 6 - 12 mm, this size is comparable to that of gypsum plasterboards. The edges of the products are also framed with fiberglass, so they do not collapse from impacts during installation and transportation.

Cut aquapanel cement slabs with a knifeusing a little more force than when working with drywall. After that the panel break and separate the parts. Back wall made of fiberglass cut again with a knife.

Varieties of material

All types of reinforced mineral cement panels, regardless of the model, are tested at the factory. Manufacturers claim that the panel does not deform and won't even swell when immersed in liquid for a long time.

Produce water panels for different applications with different characteristics:

- Skylight panels;

- universal elements;

- outdoor slabs;

- internal products;

- reinforced slab for sub-floor tiles.

Cement panel Skylight used to install on the ceiling as a suspended structure... In unheated rooms and in damp rooms, the surface does not rot or deteriorate. Outside they put in open galleries, on balconies, for finishing roof overhangs... Dimensions of elements 0.9 x 1.2 meters, thickness 8 mm.

Universal Knauf water panel is installed in various versions, since its characteristics are suitable for facades, ceilings, partitions... Product dimensions 0.9 x 1.2 meters, thickness 6 mm.

Outdoor elements are mounted to work as wall decoration, filling of fences between the pillars, they are placed under the soft roofing layer... Element sizes in width 0.9 and 1.2 mm, the length release from 1.2 to 3.00 meters, thickness - 12,5.

Reinforced internal panels are for wet conditions work with regular cleaning of floors, processing of walls, ceilings, where there is a lot of steam, there is a high temperature. Panel dimensions in width 0.9 and 1.2 m, length from 1.2 to 3.0 meters, thickness - 12.5.

There are slabs that are mounted as a base layer for facing with tiles or ceramic tiles... They are standard size 0.9 x 1.2m, thickness is 6mm.

The difference between panels for interior and exterior decoration

External panels work under conditions of constant exposure to adverse atmospheric factors... They are affected by atmospheric chemistry in the form of alkalis, acids, and solar ultraviolet light. Plinth panels are close to the ground, so they are covered with snow, drops of car oils and exhaust particles fall on the surface. In addition, the walls are kicked.

Facade products must firmly resist the above factors. When installed as a curtain wall, it is possible to mount insulation and waterproofing

The sun does not affect the inner plates, therefore, they do not contain ultraviolet traps. But such products must withstand internal vapors and high humidity, therefore, hydrophobic additives.

Features of the installation of water panels on the example of Knauf products

Need a strong crateto withstand the mass of mineral cement sheets. Wooden slats before installation impregnated with linseed oil 3 timeswait for each layer to dry. Also used store impregnation against inflammation, moisture, microorganisms.

For a steel profile, such procedures are not necessary., so this particular type of frame is chosen most often. The metal profile has a greater bearing capacity than wood.

At the joints of the floor and ceiling finishes, small technological gaps;

- at the floor they are made 10 mm wide;

- do not cover a 6 mm gap at the ceiling.

The material is cut and hung on the crate. Element step the frame is made depending on the width of the panels, in multiples 30, 40 or 60 cm... The assembly seams between the sheets are sealed with polyurethane sealant.

Ceiling installation

Ceilings do together with interior decoration, before finishing the floor covering. Before work finish the electrical wiring, set ventilation boxes.

Ceiling decoration process aquapanels includes works:

- marking the position of the frame parts;

- assembly of the battens, fastening elements to the floor slab;

- fixing the plates to the frame;

- putty, gluing joints;

- priming of the entire surface, putty and painting.

In wet rooms wooden slats are not used, but put galvanized profile from the g / cardboard fastening system. The profiles are placed on the plate for hangers (ES brackets), which are fixed with plastic dowels. Metal elements hold together self-tapping screw "flea".

The resulting surface does not belong to load-bearing structures, has a smooth surface without seams, on which wallpaper is glued or painted. To fix the load on the ceiling, expanding screws (butterflies) are used.

Assembly of partitions

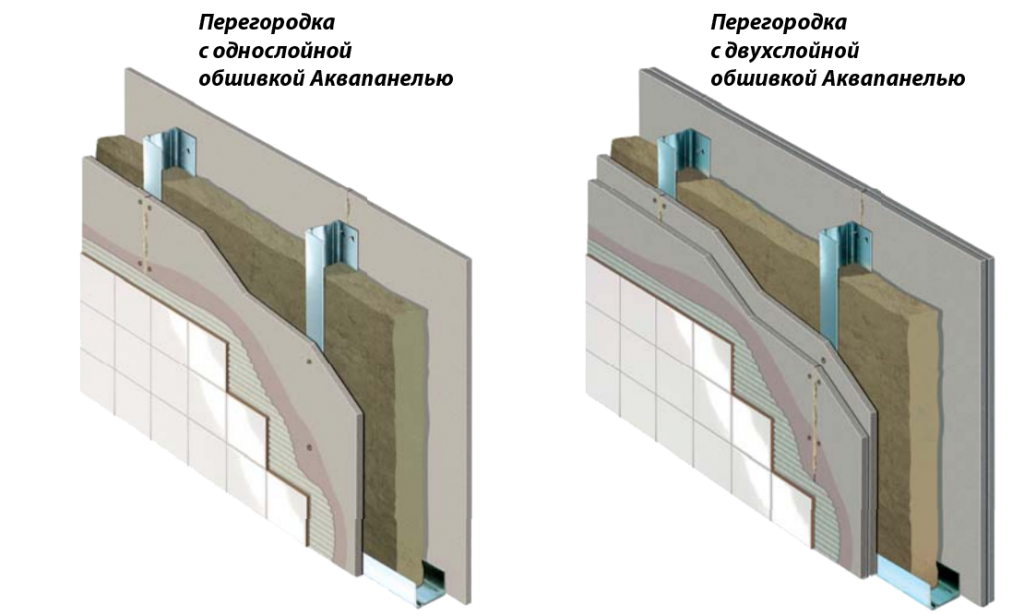

Allows connection of racks along the length overlapped (the length is equal to the section multiplied by 10), or use additional section of the profile (the length is equal to the section size multiplied by 20). Wooden posts are connected with steel plates.

Device rules:

- the joints of the profiles are staggered;

- the upper horizontal girders are connected above the racks, and the lower ones - between them;

- to the floor, ceiling, the parts are fixed with dowels;

- between the walls, ceiling, floor and guide profile, a sealing and sound-absorbing tape is placed;

- metal profiles are fastened to each other using punching methods with bending the edges of the holes.

The joints between the slabs are treated with glue, which is applied to the edges of the sheets before installation. This technique excludes the use of reinforcing serpyanka at the seams. The end joints are shifted by a step of the racks. In a two-layer design, the first layer is also displaced in relation to the joining of the elements. The panels can be cut if necessary, this does not reduce their quality.

Mounting methods

Adhesive composition for seams of aquapanels, they are used according to the manufacturer's recommendations. Reinforced cement sheets are attached to metal racks, girders self-tapping screws, countersunk screws. Be sure to take hardware with galvanized layer on a surface... Step between the screws - not less than 25 cm.

With a horizontal vertical method of arranging sheets the smooth surface of the panel is turned outward, while the rough surface remains inside the structure... Self-tapping screws are placed from the edge of the sheet at a distance of 15 mm. When installing slabs between them, provide technical gap of 3 - 5 mm... To do this, take spacer wedges or screws.

Panels on ceilings, walls, floors and as partitions check for horizontal, vertical a building level, and a carpenter's square is used to check right angles.

Safety and Transport Regulations

Transport aquapanels horizontallypacked in bags. Packages have on wooden pallets of sufficient rigidity so that the sheets do not bend. When unloading, the slabs do not hit, and do not drop from a height.

Safety regulations:

- If the panels are placed outdoors, it is prohibited to work in the rain with a power tool.

- Workers use only serviceable tools, and installation at a height is carried out from a stable scaffold, stairs, scaffolding (on the street).

- False ceilings are made with an assistant, despite the relatively low weight of each sheet.

- For work, they put on overalls and personal protective equipment.

The material is stored on pallets in closed warehouses without the possibility of mechanical damage. The storage rules allow the storage of packages with panels of several pieces in height, while the stack should not exceed 3 meters. Hooks, hooks of cranes are equipped with soft pads so as not to destroy the surface of the panel when jerking.