A subspecies of gypsum is called alabaster; it is made from natural gypsum stone. The oldest building material has been used for more than five centuries, it is popular, despite the many new dry mixes. The material has unique qualities, fast solidification, so working with it requires a special technology.

What is alabaster

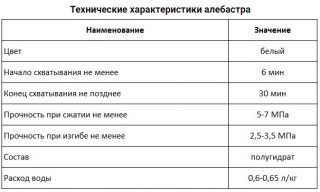

Alabaster characteristics:

- white, yellowish, pinkish or gray dry powder, opaque and microporous;

- permeates with water if stored in humid conditions.

In solutions alabaster plays the role of the binder. Differs in fast setting due to the content of large grains, which serve as catalysts. A particularly valuable property in construction is its high adhesion to surfaces.

Structure

Alabaster contains impurity coarse sand, is a type of gypsum. It is produced from gypsum stone (calcium sulfate) by grinding and firing at + 180 ° С.

Chemical gypsum and alabaster formulas:

- gypsum - dihydrate, expression CaSO4 · 2H2O;

- alabaster - semi-aqueous, formula CaSO4 · 0.5H2O.

Alabaster particles in the composition are smaller than that of gypsum, therefore it is less elastic, more durable, and hard. Gypsum is more often used in medicine, casting of blanks, jewelry craft, art. Alabaster is used for construction and decorative work.

Two-water gypsum in a high-temperature mode in open chambers turns into semi-water, resulting in a β-modification material. If the heat chamber is closed hermetically, a high-strength α-modification gypsum is obtained.

Varieties and properties

Distinguish three types of alabaster:

- Calcite... They are made from stalagmites of limestone caves or travertine formed by water currents. It is called marble onyx.

- Plaster. Common building materials are mined in different countries.

- The black. A rare species found naturally in Oklahoma, China and Italy.

Fast hardening species are designated A (2 - 15 minutes), normally hardening - B (6 - 30 minutes), slow-hardening - In (20 or more minutes). Compressive and flexural strength - 4 and 2 MPa. For mixtures, particle boards, g / cardboard take stamps G5 - G6, for high-strength products they use grades G13 - G25. According to SNiP, it is indicated water consumption 0.65 - 0.7 liters per 1 kg of powder.

Scope of application

Other use cases:

- in the production of gypsum board panels, dry plaster boards, ventilation boxes, gypsum boards and fibrous sheets;

- high-strength arches are used to create sculptures, ceramics;

- in foundry they are used for the manufacture of water-absorbing formwork, sealing holes.

Selection criteria for renovation

Choose a product taking into account that the material absorbs water if stored improperly... Alabaster it is better to buy in a hardware storex, and not in markets where there are no conditions for preservation. They buy such a quantity that it is enough to complete the work, and there are no leftovers.

Inspection and purchase rules:

- Check the integrity of the bags. Torn walls indicate that the product has absorbed moisture somewhere, has lost its properties.

- Well-known manufacturers are a priorityand even if their products are more expensive. They have an established production cycle in compliance with technology.

Buy products with a certificate of quality and conformity... It is better if the brand is indicated on the label, there are instructions for making the mixture.

Mixing rules

The technology of diluting the powder with water is of particular importance - fast setting requires a special approach. First, water is poured into the container, then the dry substance is poured (not vice versa).

Other rules cooking:

- while mixing, the powder is introduced little by little, while constantly kneading until smooth;

- in case of hardening, the solution is thrown away, since it will no longer be possible to reanimate it;

- applying to the surface, you need to remember that after drying, the material will add a little in volume.

The behavior of the mixture depends on the grade of alabaster and even the delivery batch. To see the speed of solidification, you need to make a small test batch (about 100 g of powder).

Preparing the container

The result of the work depends on the container where mixing will take place. There will be a lot of adhered stone mortar on the walls, which will need to be disposed of before the second batch.

When choosing, you need to consider:

- metal containers are not suitable, since diluted alabaster will firmly grab the iron;

- dried residues on the walls of the plastic container accelerate the already fast hardening;

- it is convenient to use soft containers and a tool made of semi-rigid material.

Dilution with water

The proportions of the mixture depend on the goal to be achieved.

Proportions depending on the different jobs:

- alabaster mortar for plaster, leveling, putty - 0.65 l per 1 kg of alabaster;

- for repair and assembly personnel - 0.5 liters per 1 kg;

- liquid solution for putty - 1 liter per 1 kg.

Dissolve dry powder only with cold water... Hot will accelerate hardening so much that it will not even be possible to mix the mass. Stir quickly and vigorously so as not to waste minutes of the life of the solution.

How to extend the setting time

Experienced craftsmen know how to delay the time of turning alabaster into stone. There are completely scientifically based methods, other methods are folk, but they also have a right to exist.

Supplement options:

- Bone glue. Any glue from this series is used (painting, carpentry). Enter only 2% of the total mass.

- Lemon acid. Typically, for half a glass of alabaster, several acid crystals are counted. It is dissolved in water, where the powder will be added.

- PVA glue. 3% by weight is added to the mixture.

The amount of citric acid is also selected empirically. The amount of this modifier depends on the brand of alabaster and its strength.

Recommendations for working with the solution

The first step in the work is splashing. For application, use a construction steel trowel without defects. The spray is performed by sharp throws of the solution onto the wall away from you. The force must be calculated correctly so that the solution does not bounce off the wall and hit the floor.

Primer and topcoat applied with a wide spatula. It is better to install beacons so that they work as a rule. When the cover dries a little, take construction grater made of plastic, and process the surface in a circular motion, pressing the tool to the plane.