Reinforcement is a collection of various metal structures intended for strengthening. Most often, such products are used in construction to reinforce concrete structures. Concrete can withstand bearing loads well, but is not resistant to tension, compression or bending load. The metal frame provides these properties.

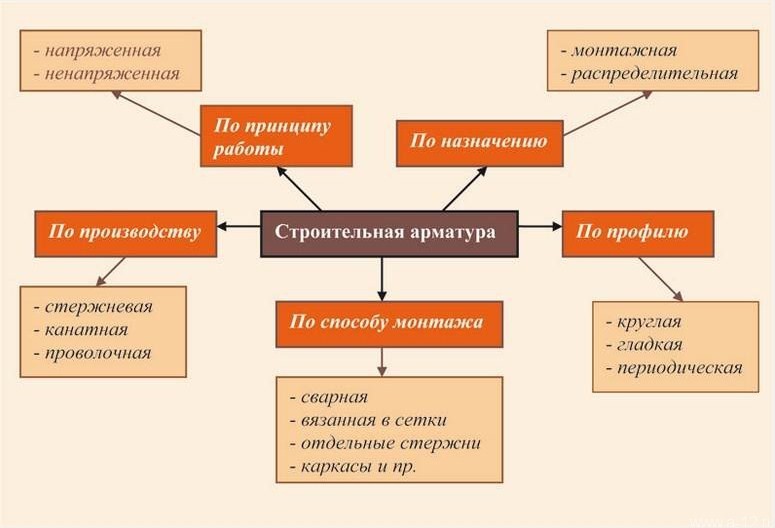

General classification of fittings

By appointment rods are divided into 4 classes.

- Working - perceives the effort from the main load. Its dimensions are calculated according to the maximum effort.

- Constructive - designed to compensate for the load during shrinkage, expansion, compression. Calculated by the minimum percentage of reinforcement.

- Mounting - combines the working structural reinforcement into one whole and evenly distributes the load.

- Anchor - embedded parts to which the supporting structures are welded.

By rod type - corrugated or smooth.

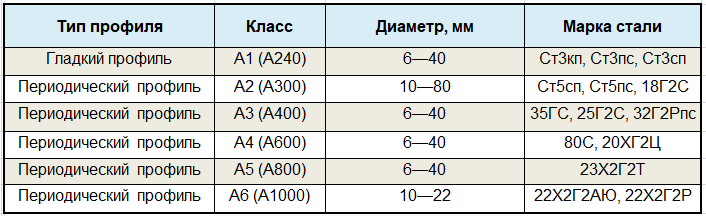

By mechanical properties there are 5 classes.

- A1 (A240) - hot rolled smooth steel, usually round. The diameter of the bar is not more than 12 mm, it is produced only in the form of bars.

- A2 (A300) - corrugated bar. The vertical ridges are spaced with a large pitch. Almost not used now.

- A3 (A400) - round steel profile periodic. Manufactured from alloyed and low-alloyed structural steel. Due to its ease of welding, it serves as the main material for reinforcement. Maps and grids are made from the rods.

- A5 (A600) - the diameter of the bar is 6–36 mm. The reinforcement is taken for structures with long runs. The rods are suitable for the construction of prestressing frames.

- A6 (A800) - hot rolled corrugated fittings. To increase the strength of the product, the intermittent cooling method is used. The rods are used for tension frames.

There are many types of rolled products that occupy an intermediate position, for example, the A500 class.

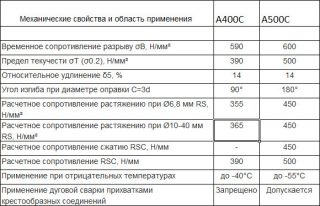

Features of A500S fittings

A500C fittings are rods and wires obtained reinforcing carbon steel... Its main difference is before production, the alloy is heat-hardened... For this, the workpieces are heated until high plasticity appears, and then rolled through the mill. The relief of the product is formed on the rolls.

The bar is quenched with water to form an upper quench layer. The rod is then transferred to the refrigerator where the final structure is formed. As a result, a hot-rolled product has almost the same strength characteristics as a cold-rolled one, but at the same time it is affordable.

Testing

Before release, take samples of the batch and check:

- assess the surface - the appearance of cracks, films, shells, sunsets on the surface is not allowed. Local atmospheric rust is considered a normal variant;

- check the diameter of the bar, curvature, compliance with the length;

- estimate the yield point, tensile strength, these studies are performed before electric heating;

- bend tests are performed with a certain radius with a bend.

Standard indicators, as well as tolerances, are given in GOST 34028-2016.

Specifications

The A500S fittings have the following properties:

- Density - depends on the type of steel used.

- Yield point - 500 N / sq. mm.

- Temporary resistance - 600 N / sq. mm.

- The ratio of the actual values is 1.05.

- The elongation is 14, 2 and 2.5, respectively.

- Electric heating temperature for A500C fittings is not measured.

All product characteristics are indicated in the manufacturer's certificate and on the packaging.

Decoding

- letter A - hot-rolled rod, thermally and mechanically hardened;

- 500 - yield point;

- FROM - indicates the ability to weld the material.

A500SP is also produced. This variety has high adhesion to concrete.

Dimensions, weight

The range of A500C fittings is described by GOST. Rods are produced according to the current standards diameter from 4 to 40 mm... The weight of 1 running meter of the product fluctuates from 0.099 to 9.865 kg. The measured length of the products is 6-18 m.

The production of rods of measured and unmeasured lengths in the range from 6 to 12 m is allowed.

Application of fittings А500С

Thermo-mechanically reinforced rods are used in the following areas:

- when reinforcing walls, columns, arches, foundations;

- in the production of reinforced concrete structures of any type;

- upon receipt of floor slabs, arch elements for bridges.

A500C fittings are not suitable for use in severe weather conditions.

Transport and storage

The packaging material and the number of straps are determined by the customer.

Rolled metal is transported by ordinary freight transport. Stored in warehouses in low humidity conditions.

Installation nuances

Plus fittings of this class - easy weldability. The frame of the rods is fixed by welding, and not by tying, as is the case, for example, when using the A300 or A400. In addition, the material can be used as embedded parts.